Balancing piston seal assembly of mud pulser

A technology for balancing pistons and mud pulses, which is used in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems affecting the normal operation of MWD/LWD instruments, the pulser cannot work normally, and the fatigue strength is low and not durable. To achieve the effect of good sealing performance, not easy to be punctured, and reliable life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

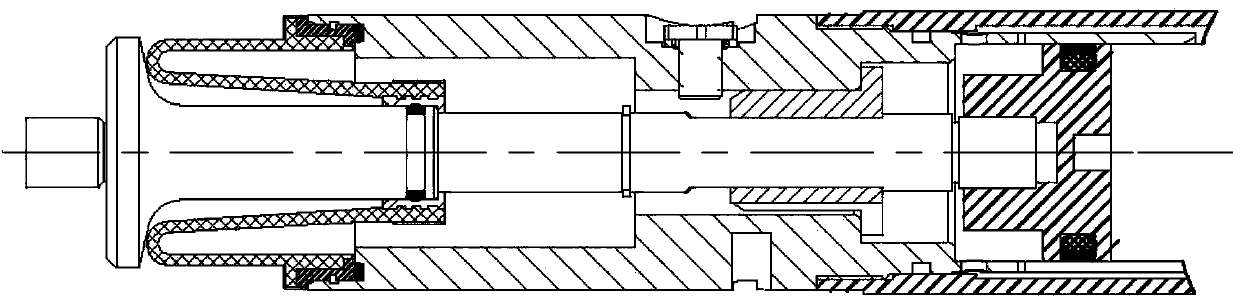

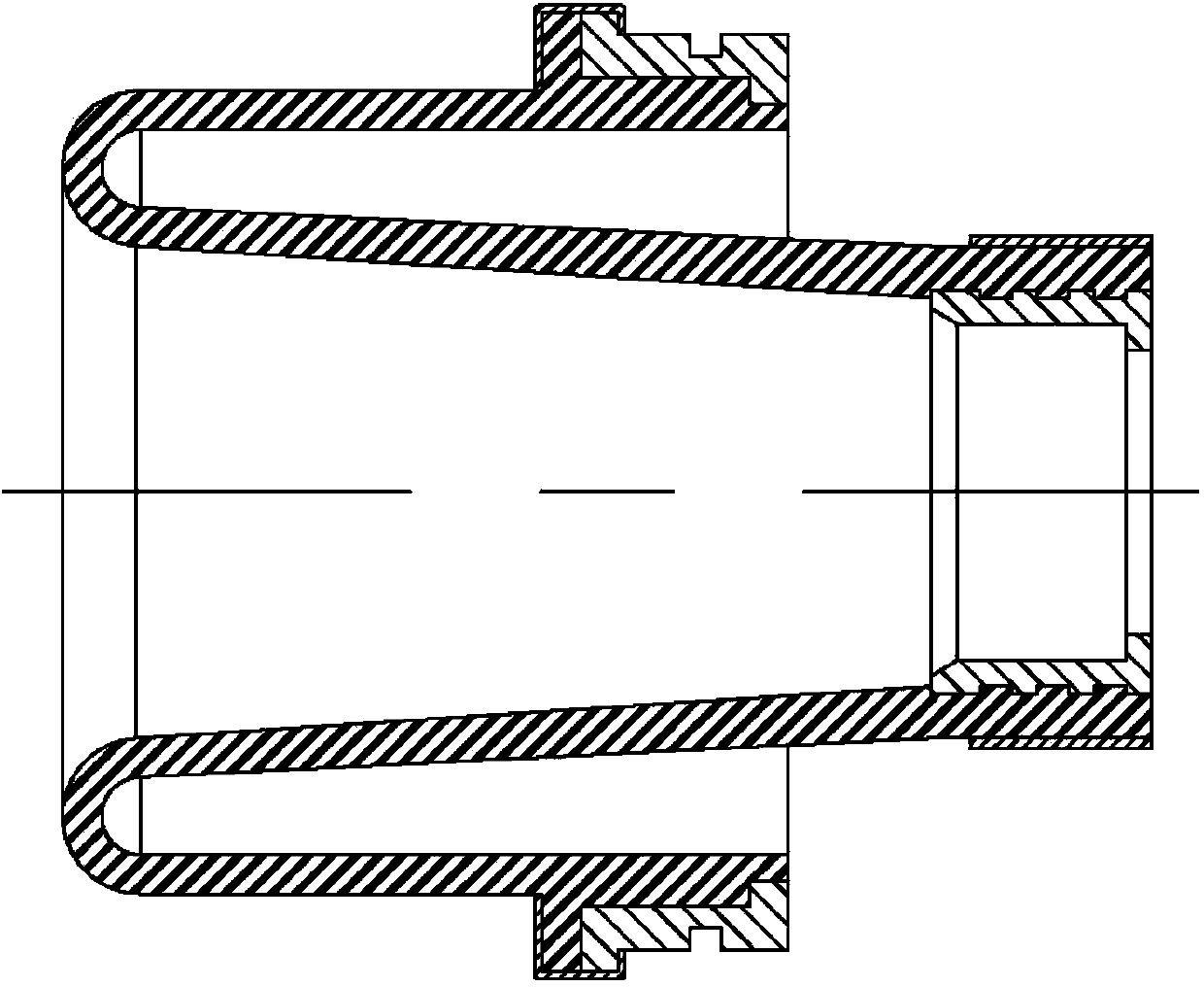

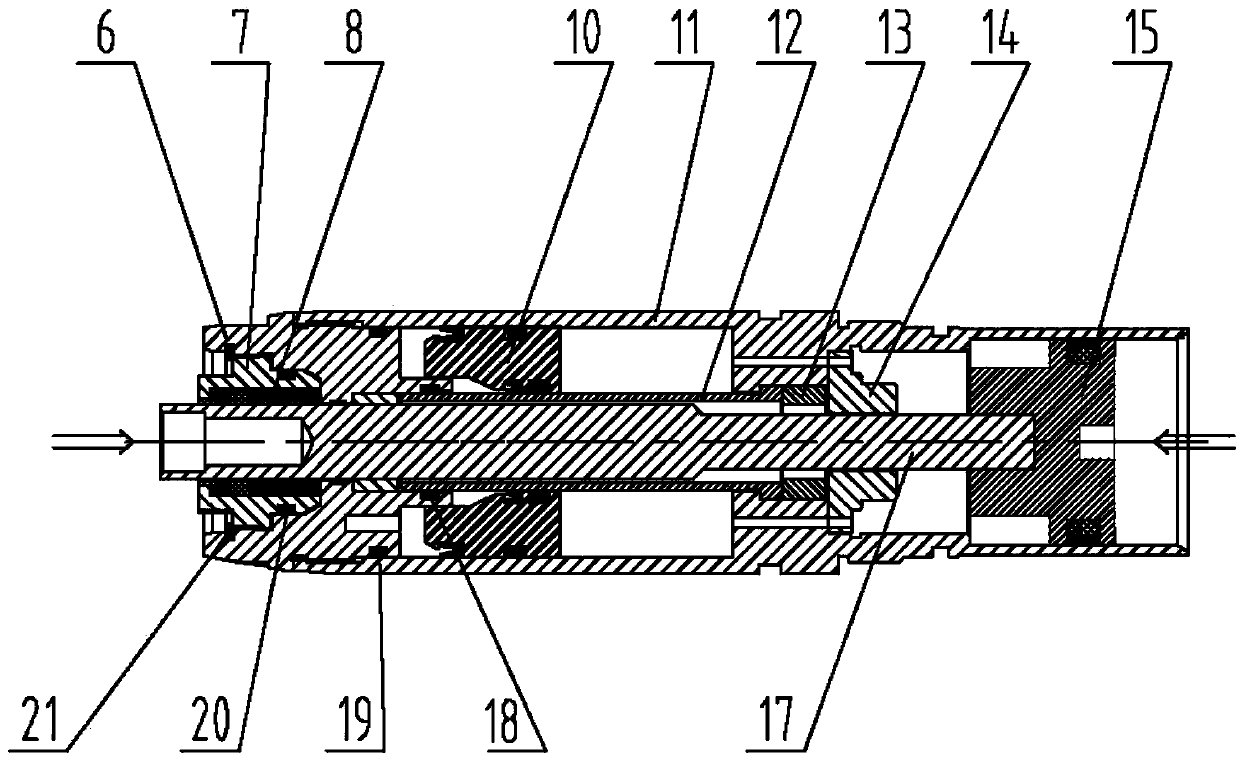

[0023] A mud pulsator balance piston sealing assembly, including a housing 11, a balance piston 10, a lifting rod 17, a piston 15, a guide pipe 12 and a top plug 6, the balance piston 10 is arranged in the housing 11, and the inside of the housing is divided into a mud chamber And the oil chamber, the top plug 6 is arranged in the mud chamber, the top plug 6 has a mud flow channel 9, the mud flow channel 9 communicates with the mud chamber, the guide pipe 12 passes through the balance piston 10 and connects with the top plug 6 Connected, the lifting rod 17 passes through the guide pipe 12 and the top plug 6 and extends out of the top plug 6, the lifting rod 17 is connected with the piston 15 at one end of the oil chamber, and the piston 15 is arranged in the oil chamber. Mud and hydraulic oil are separated by balance piston 10 to prevent mud from contaminating the hydraulic oil.

[0024] In order to better fix the guide pipe 12 and avoid displacement affecting the stability, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com