Offset cutter and coal plow for planer

A technology of cutting tools and planing heads, applied in the field of offset cutting tools and coal plows, can solve the problems of difficulty in planing, wear of planing tools, falling off of picks, etc., to improve the stress condition, increase the thickness of the outer wall, reduce the The effect of the probability of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

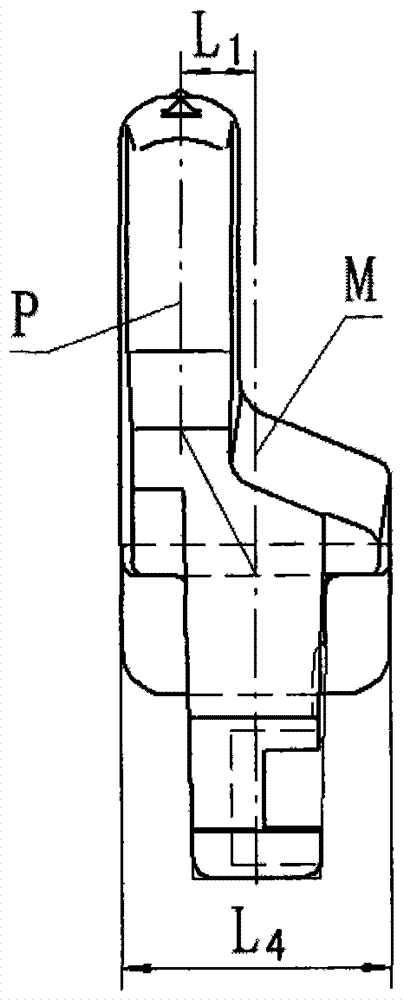

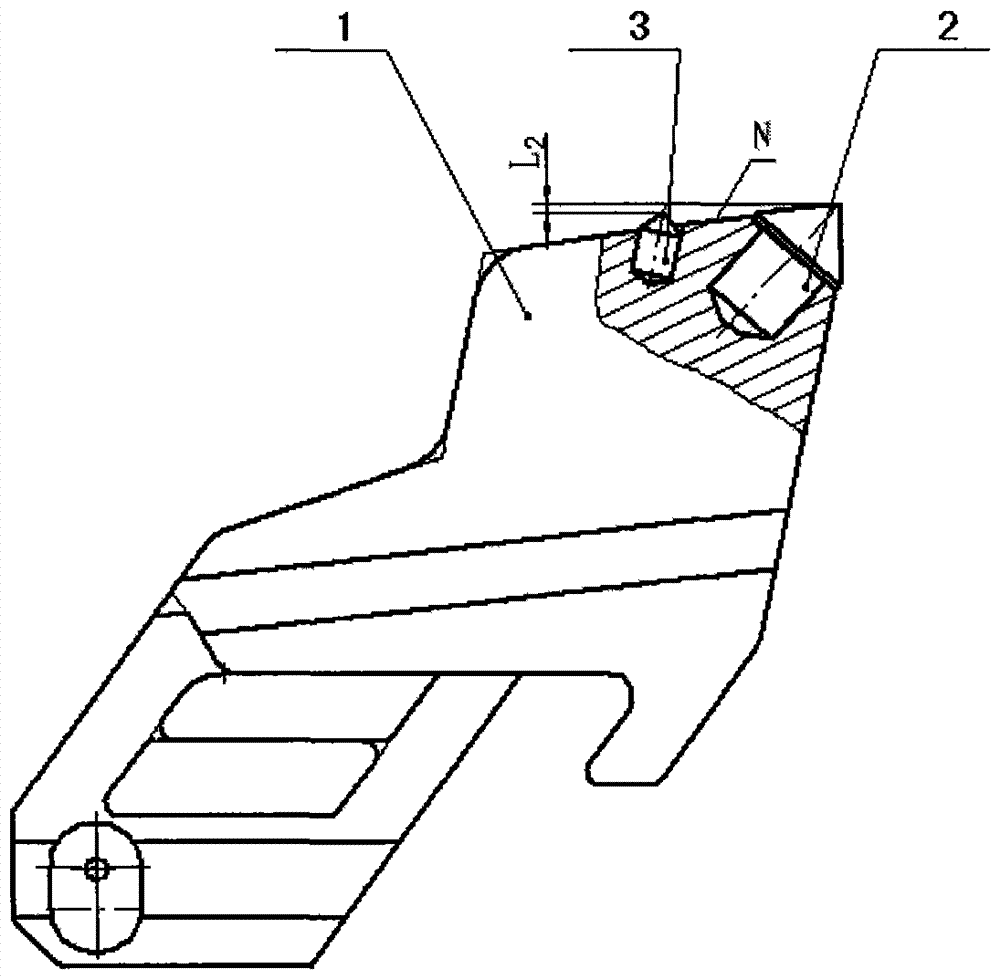

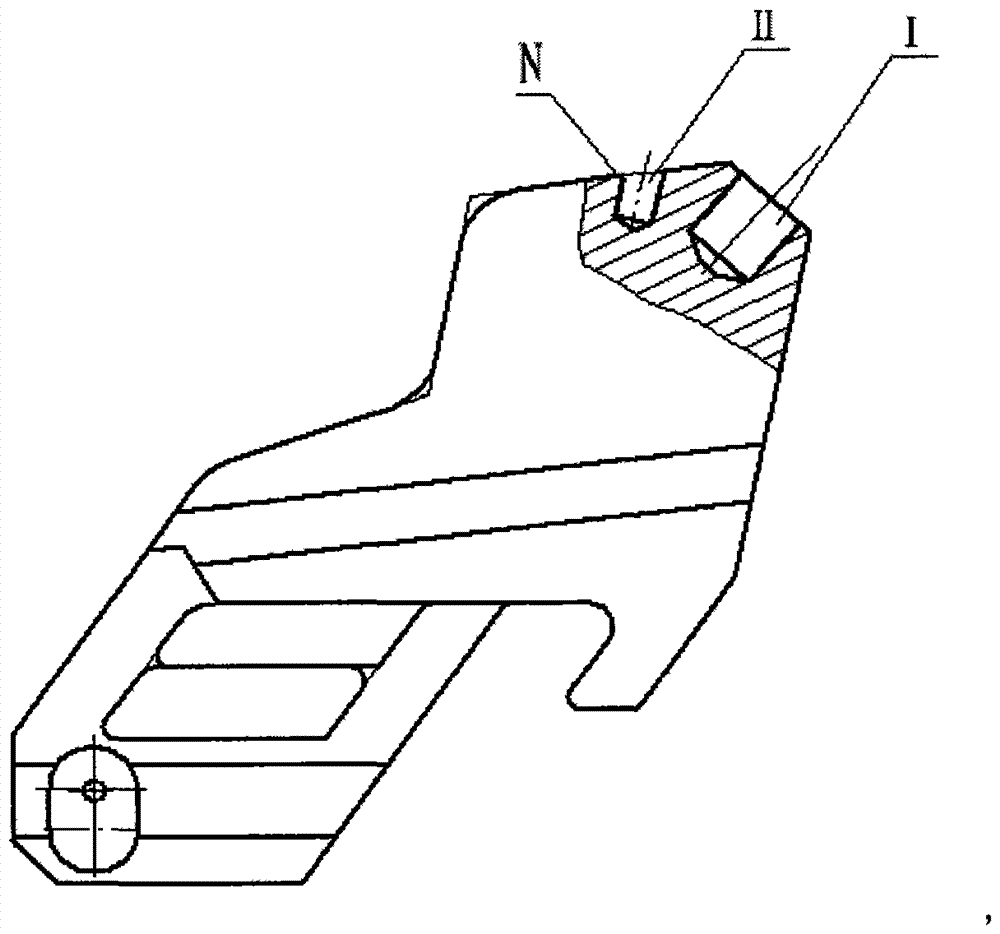

[0019] like Figure 1~4 As shown, it includes cutter body 1, umbrella-shaped pick 2 and cylindrical pick 3; cutter body 1 is an offset asymmetric structure, and the center P of the head of the cutter body is relatively offset from the center M of the shank of the cutter body. The surface N is provided with pick holes I and II, the center of the pick hole coincides with the center P of the head, and the offset distance L of the center P of the head of the cutter body 1 relative to the center M of the handle of the cutter body 1 is the cutter body thickness L 4 1 / 8 to 3 / 8 of that.

[0020] The umbrella type pick 2 and the cylindrical pick 3 are respectively embedded in the pick holes I and II provided on the cutter body 1, and are fixed by brazing. The umbrella-shaped structure not only ensures the welding area between the pick and the cutter body, but also increases the thickness of the outer wall of the pick hole I of the cutter body, effectively reducing the probability of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com