Automatic and random grouping push control system of shield tunneling machine

A technology of propulsion control and shield machine, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as reducing construction efficiency, lengthening construction period, affecting construction quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

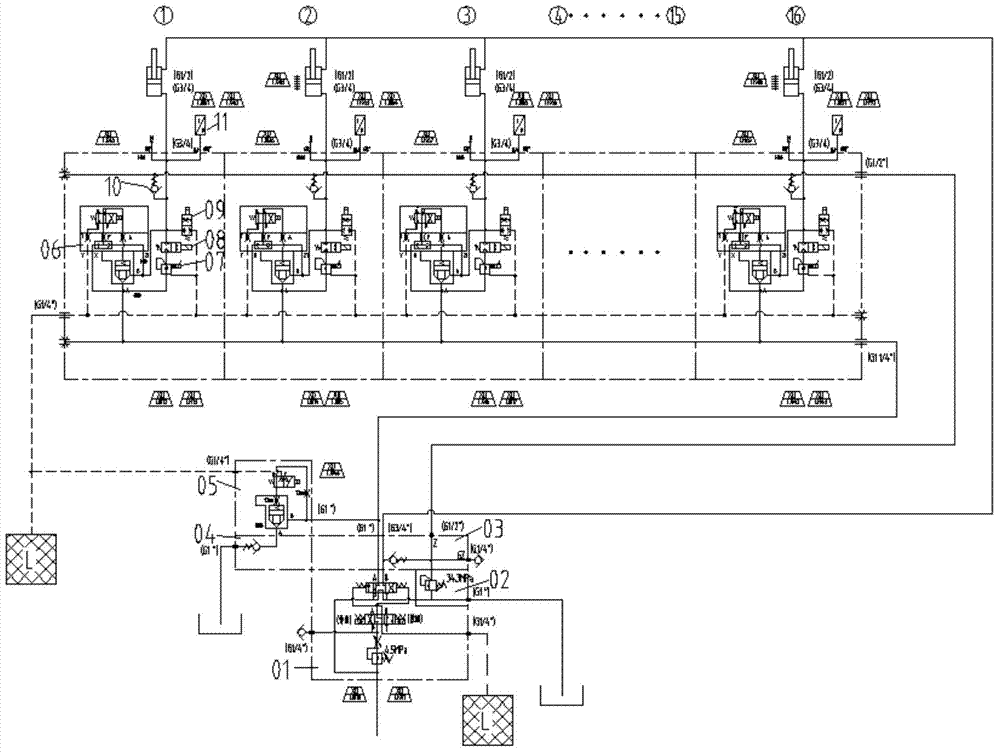

[0021] Such as figure 1 As shown, the present invention discloses a shield machine automatic arbitrary grouping propulsion control system (oil cylinder control can be grouped arbitrarily), including multiple groups of propulsion cylinder thrust control devices and a group of propulsion cylinder reversing control devices, multiple groups of propulsion cylinder thrust control devices The signal control end of the device and a set of propulsion cylinder reversing control devices are connected to the host computer of the shield machine, and the host computer sends signals to multiple sets of oil cylinder thrust control devices and a set of propulsion cylinder reversing control devices, which are realized by adjusting the maximum thrust of the oil cylinders. Real-time adjustment of the propulsion attitude of the shield machine.

[0022] figure 1 Shown is a group of propulsion cylinder reversing control devices, 16 groups of propulsion cylinder thrust control devices The reversin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com