Gentle tilt angle mining structure

A technology of gentle inclination and angle, applied in the field of mining working face layout in inclined seams, can solve problems such as hindering the economic development of mining in gently inclined seams, less mining and unloading, and non-proportional input and output, so as to achieve high mining rate and mining efficiency and reduce Mining cost, ease of implementation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

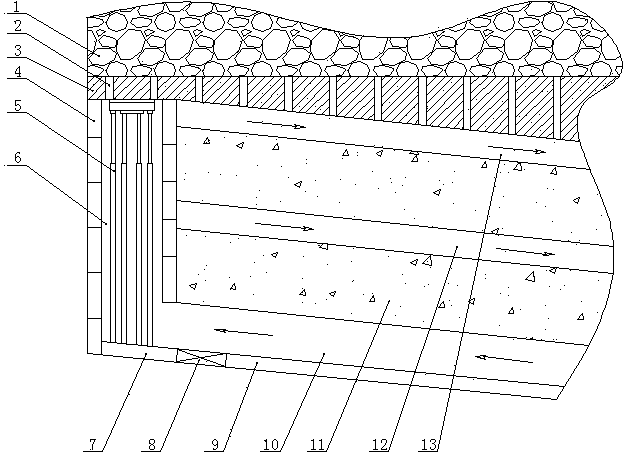

[0011] Example: such as figure 1 As shown, a mining structure with a slight inclination angle is provided with a return airway 13 on the topmost layer of the layer to be mined, and a transportation roadway 12 is provided at equidistant intervals from top to bottom in the layer to be mined 11, and the transportation roadway 12 is waiting The inclined surface of the mining layer is laid out, and the transport roadway 12 and the air return roadway 13 are connected with the external air return shaft. At least one air inlet roadway 10 is provided on the lowermost layer of the layer to be mined 11 along its inclined surface, and the air inlet roadway 10 communicates with the air inlet shaft. A mining roadway 6 is opened at the mining face of the layer 11 to be mined, and the mining roadway 6 communicates with the transportation roadway 12 and the air inlet and air return roadways 10 and 12 . A support frame 5 is erected in the mining roadway 6 of the mining face, and a scraper mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com