A Three-row Cylindrical Roller Combined Slewing Bearing with Split Structure

A cylindrical roller and slewing bearing technology, applied in the field of bearing manufacturing, can solve the problems of large size and weight of forgings, exceeding the processing capacity, processing and transporting short plates, etc., to improve the reliability of use, reduce impact and vibration, reduce The effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

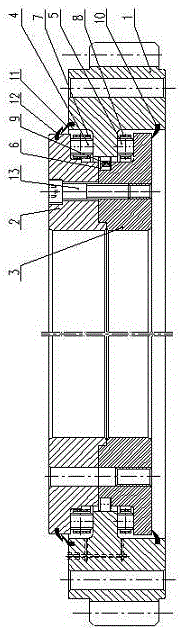

[0020] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

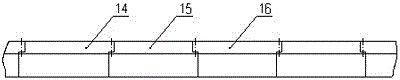

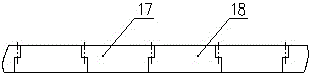

[0021] Such as figure 1 As shown, a three-row cylindrical roller combined slewing bearing with a split structure, the three-row cylindrical roller combined slewing bearing with a split structure includes a combined outer ring 1, a first combined inner ring 2 and a second combined inner ring ring 3; multiple main thrust rollers 4 are set between the combined outer ring 1 and the first combined inner ring 2, and multiple secondary thrust rollers are set between the combined outer ring 1 and the second combined inner ring 3 Thrust roller 5 and radial roller 6; as figure 2 , Figure 6 As shown, the combined outer ring 1 is a combined structure formed by lapping multiple segments of the outer ring; the split segments of the adjacent two outer rings have different structures, and the outer ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com