Cooling grid for cold storage

A technology for cooling pipes and cold storage, which is applied to coolers, household refrigeration devices, lighting and heating equipment, etc. It can solve the problems of not being able to adapt to the cooling pipes used in cold storage, no defrosting function, and few cooling guide wings, etc., to achieve optimization Appearance and durability, power saving, aesthetic appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

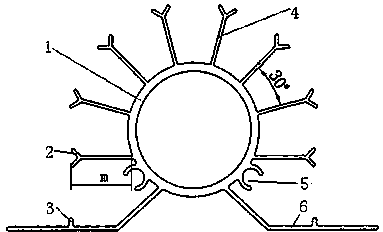

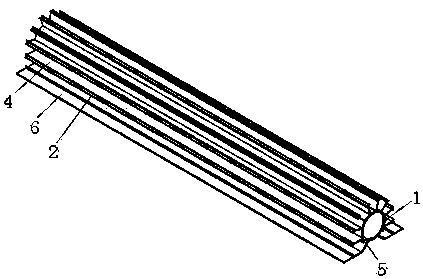

[0014] The cold storage cooling pipe of the present invention is as figure 1 , image 3 As shown, it includes the cooling pipe 1, 8 rows of cooling fins 4 and two rows of fixed wings 6, and the cooling fins and fixed wings are parallel to the axial direction of the cooling pipe. The outer end of the cooling wing is provided with a frost-climbing foot 2, and the frost-climbing foot is a Y-shaped structure. An electric fuse slot 5 is arranged between the fixed wing and the cooling wing, and the electric fuse slot is parallel to the cooling wing. The length m of the cooling fin is 25mm. The diameter of the cooling pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com