Method for preparing transmission electron microscopy (TEM) sample

A sample and preparation technology, which is applied in the field of preparing TEM samples, can solve the problems of insufficient uniformity, imperfection, and laboriousness of ion beams, and achieve the effects of ensuring quality, saving machines, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

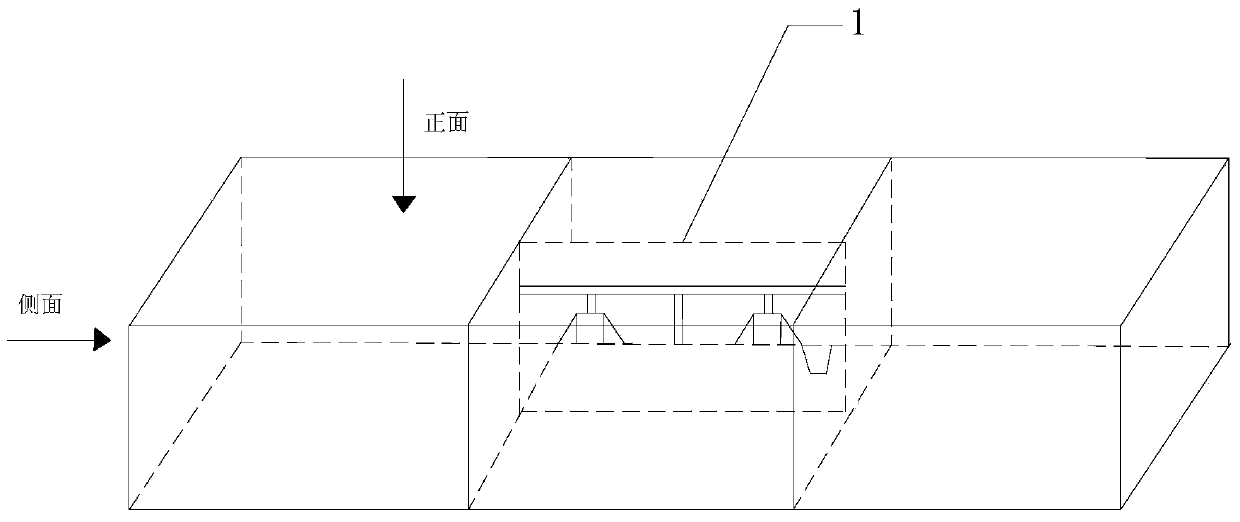

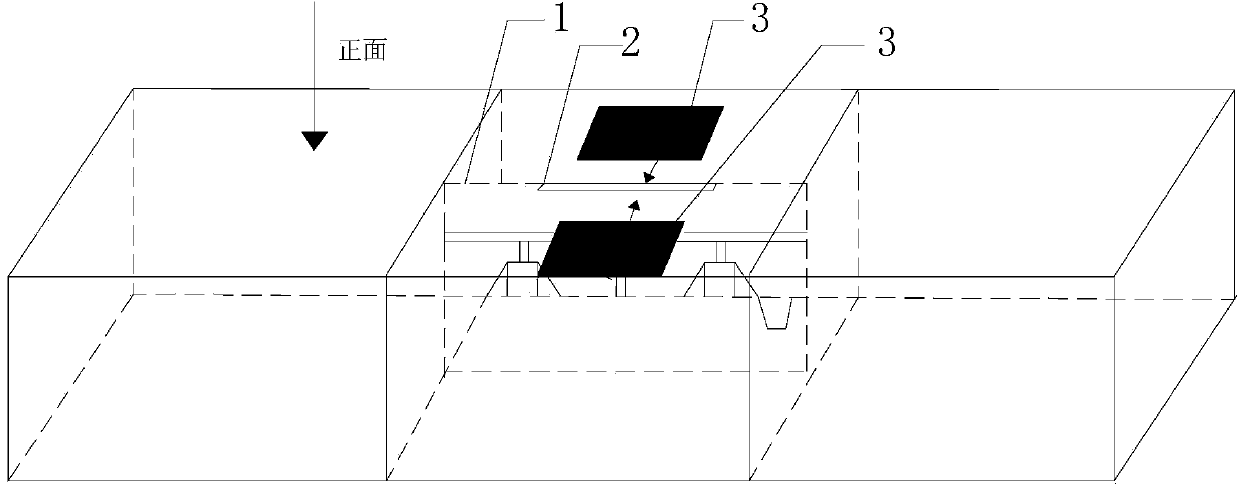

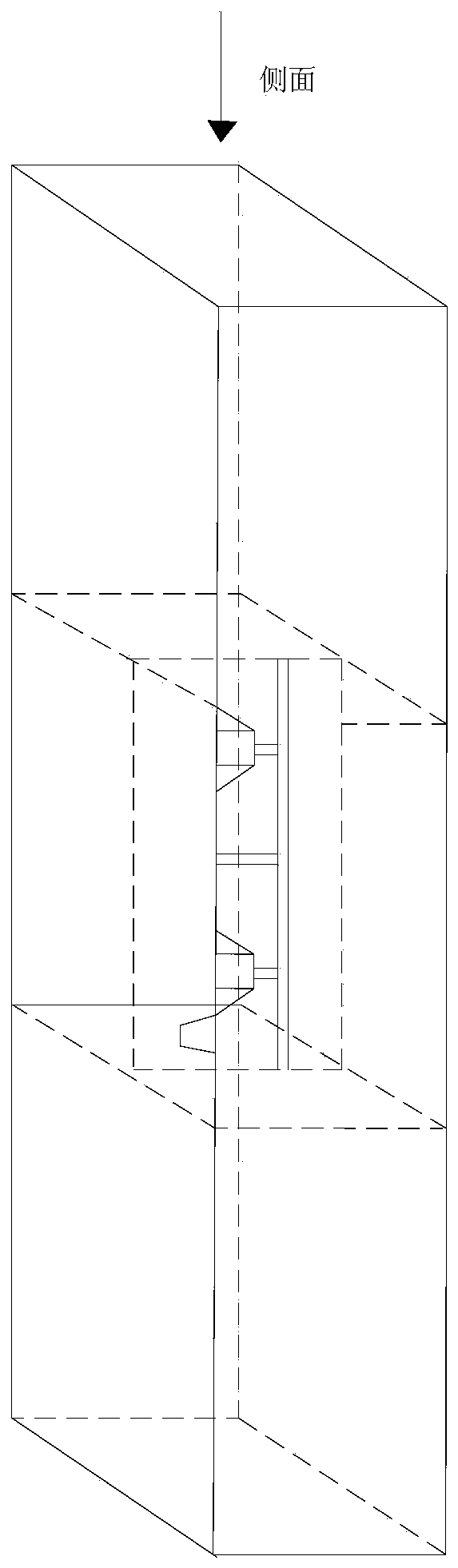

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0037] For the structure to be tested that needs to be photographed with a multi-layer structure and the thickness reaches 3 μm or more, a large pit is roughly excavated from the front of the structure to be tested to form a marking pit, and continue to thin. Therefore, the present invention provides a method for preparing TEM samples, focusing on rapid grinding from the side to the point of failure and then cutting the sample with a knife. Since the point of failure or the required structure is rotated, the depth is at most 2 μm, so The time for preparing samples using this invention will be equal to the conventional preparation time, thereby greatly saving the machine, time and labor costs. In addition, using the method of the present invention, the failure point of the failed chip and the corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com