A Data Acquisition System for Wide Plate Tensile Testing Machine

A wide-plate tensile, data acquisition and processing technology, applied in the field of data acquisition system of wide-plate tensile testing machine, can solve the problems of incomplete acquisition signals, affecting the accuracy of the test, etc., to achieve real-time data acquisition and high reliability, The effect of preventing mutual interference and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0015] The following first introduces the overall structure during the wide plate tensile test.

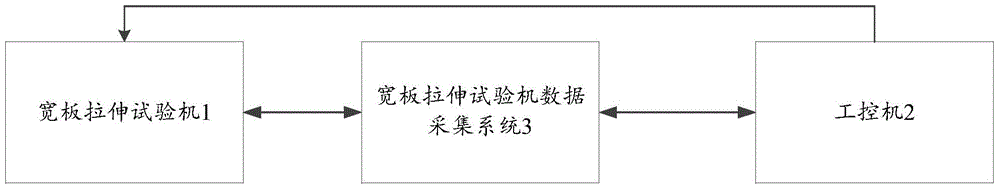

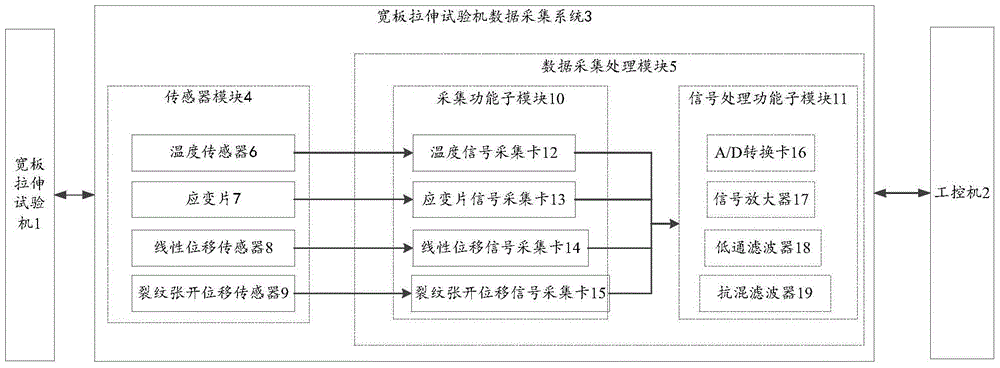

[0016] During the whole test process, three structures are involved: the wide-plate tensile testing machine 1, the industrial computer 2 of the wide-plate tensile testing machine, and the data acquisition system 3 of the wide-plate tensile testing machine.

[0017] During the test, the data acquisition system 3 of the wide plate tensile testing machine is mainly used to measure various data of the wide plate tensile testing machine 1 in real time, namely crack opening displacement signal, point strain signal, area strain signal, temperature After the signal is integrated and processed, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com