Method for measuring content of calcium carbonate in gypsum

A technology of calcium carbonate and content, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problems of rapid analysis and tedious measurement time required by unfavorable tests, and achieve Reasonable method design, accurate and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

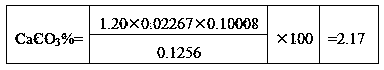

Embodiment 1

[0022] Embodiment 1, a kind of method for measuring calcium carbonate content in gypsum, its main steps are as follows:

[0023] (1) Weigh a certain amount of sample into a container; add an appropriate amount of sodium chloride solution with a mass concentration of 5%, place it on an electric heating plate and heat to a slight boil;

[0024] (2) Remove the filter, wash it with a 0.8% NaCl solution at 50°C, and put the filter paper into a container;

[0025] (3) Add hydrochloric acid solution, put it on an electric heating plate and heat to slightly boil; in the hydrochloric acid solution, the volume ratio of hydrochloric acid to water is 1:4;

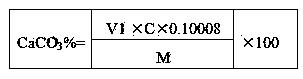

[0026] (4) Remove the filter, adjust the pH value of the filtrate to alkaline; add a masking agent, titrate the calcium ion with a standard solution to obtain the content of calcium carbonate; the masking agent is a triethanolamine solution, and in the triethanolamine solution: triethanol The volume ratio with water is 1:2.5; the stan...

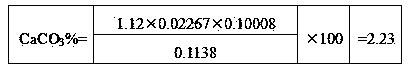

Embodiment 2

[0027] Embodiment 2, a kind of method for measuring calcium carbonate content in gypsum, its main steps are as follows:

[0028] (1) Weigh a certain amount of sample into a container; add an appropriate amount of sodium chloride solution with a mass concentration of 5-20%, and heat it on a heating plate until slightly boiling;

[0029] (2) Remove the filter, wash it with a 1.2% NaCl solution at 70°C, and put the filter paper into a container;

[0030] (3) Add hydrochloric acid solution, put it on an electric heating plate and heat to slightly boil; in the hydrochloric acid solution, the volume ratio of hydrochloric acid to water is 1:6;

[0031] (4) Remove the filter, adjust the pH value of the filtrate to alkaline; add a masking agent, titrate the calcium ion with a standard solution to obtain the content of calcium carbonate; the masking agent is a triethanolamine solution, and in the triethanolamine solution: triethanol With the volume ratio of water is 1: 5; Described sta...

Embodiment 3

[0032] Embodiment 3, a kind of method for measuring calcium carbonate content in gypsum, its main steps are as follows:

[0033] (1) Weigh a certain amount of sample into a container; add an appropriate amount of sodium chloride solution with a mass concentration of 10%, and heat it on a heating plate until slightly boiling;

[0034] (2) Remove the filter, wash it with a 1% NaCl solution at 60°C, and put the filter paper into a container;

[0035] (3) Add hydrochloric acid solution, put it on an electric heating plate and heat to slightly boil; in the hydrochloric acid solution, the volume ratio of hydrochloric acid to water is 1:5;

[0036] (4) Remove the filter, adjust the pH value of the filtrate to alkaline; add a masking agent, titrate the calcium ion with a standard solution to obtain the content of calcium carbonate; the masking agent is a triethanolamine solution, and in the triethanolamine solution: triethanol The volume ratio with water is 1:3; the standard solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com