Blast furnace multiple working condition fault separation method and system based on sparse contribution plot

A technology of fault separation and multi-working conditions, which is applied in the direction of electrical testing/monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

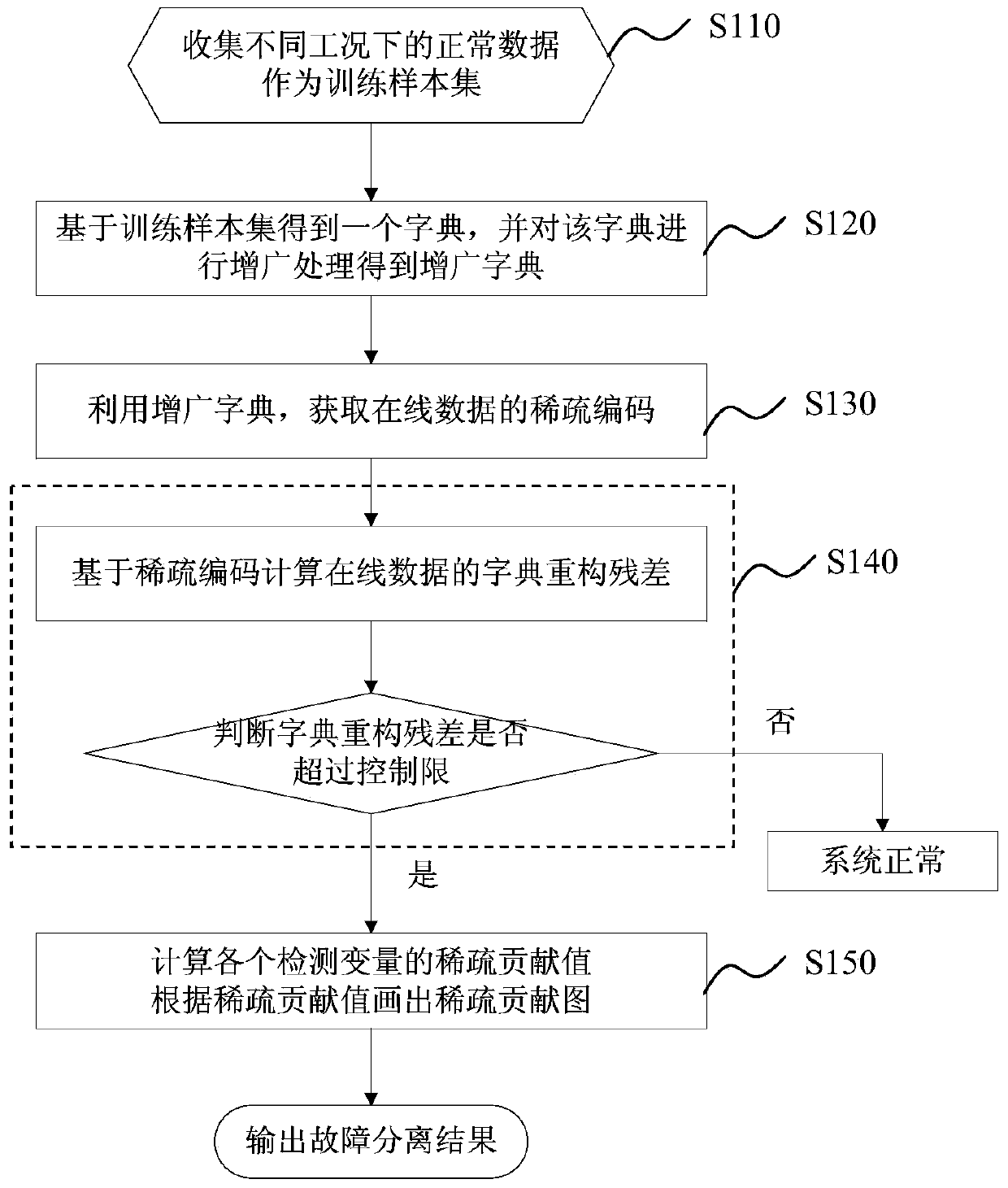

[0049] figure 1 is a schematic flow chart of the blast furnace multi-working condition fault isolation method based on the sparse contribution graph according to the first embodiment of the present invention, and the following reference figure 1 Each step of this implementation will be described in detail.

[0050] In step S110 (the word "step" is omitted below), normal data corresponding to each detected variable under different working conditions are collected as a training sample set.

[0051] Taking the blast furnace system as an example, the normal data corresponding to different detection variables under different working conditions are generally collected from the process database. The detection variable is the physical quantity to be collected by the sensor installed inside the blast furnace system, such as furnace top pressure, hot air temperature, cold air flow rate, cold air pressure, soft water temperature, hot air pressure, etc. There are more than 30 detection v...

no. 2 example

[0099] Figure 7 is a schematic structural diagram of a blast furnace multi-working-condition fault isolation system based on a sparse contribution graph according to the second embodiment of the present invention. Refer below Figure 7 Describe the components and functions of the system.

[0100] Such as Figure 7 As shown, the system includes a data collection module 71, a dictionary augmentation module 73 connected with the data collection module 71, a sparse coding module 75 connected with the dictionary augmentation module 73, a fault detection module 77 connected with the sparse coding module 75, and A fault separation module 79 connected with the fault detection module 77. The data collection module 71 , dictionary augmentation module 73 , sparse coding module 75 , fault detection module 73 , and fault separation module 79 of this embodiment respectively execute steps S110 , S120 , S130 , S140 and S150 of the first embodiment. It will not be expanded in detail here....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com