Polymer battery as well as encapsulating mold and encapsulating method thereof

A polymer and battery technology, applied in the isolation of batteries and their environment, secondary batteries, battery pack components, etc., can solve problems such as numerous processes, complex processes, and extended product development cycles, and achieve process simplification, reduce mold cycle, The effect of material cost and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings of the embodiments of the present invention.

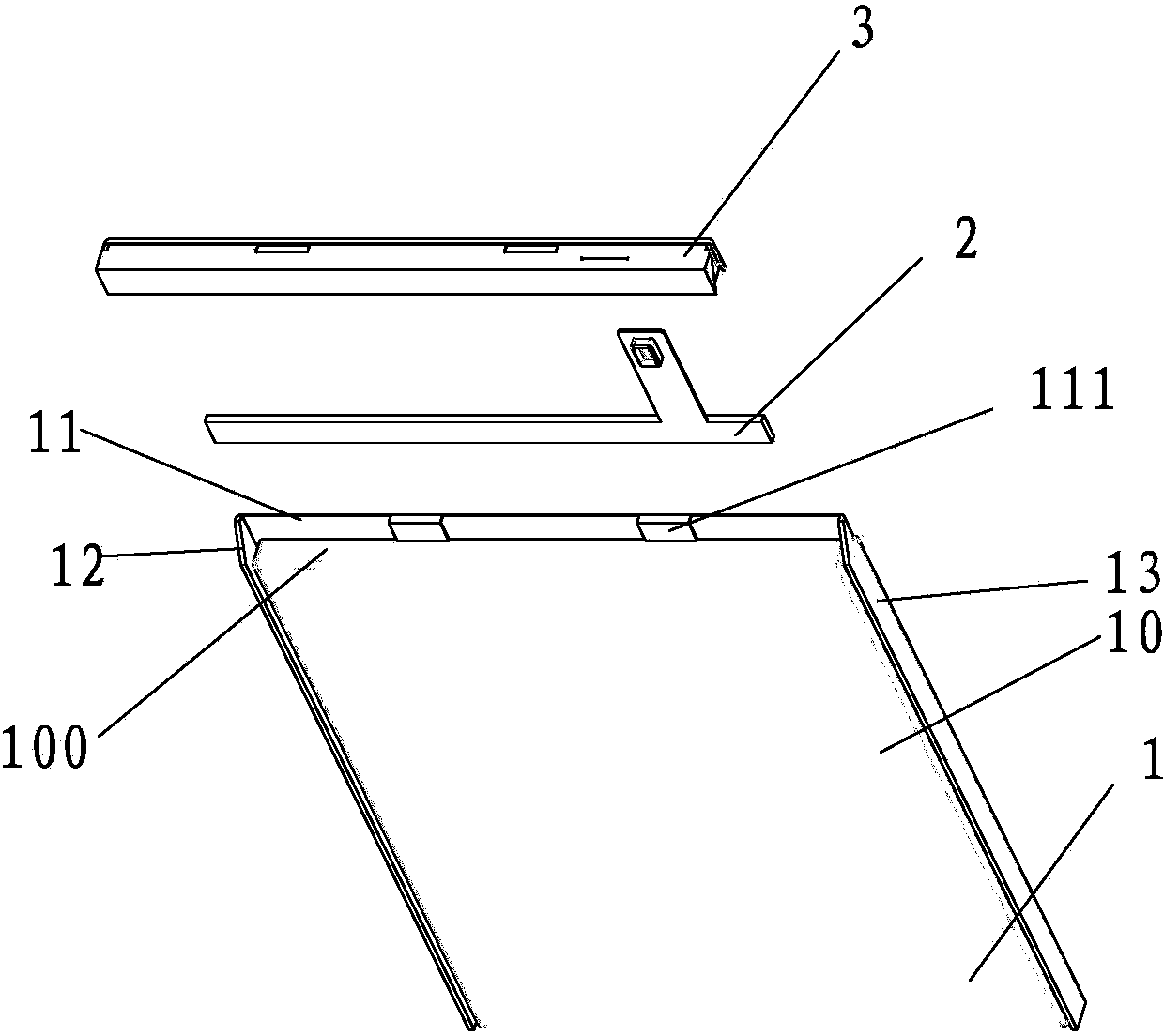

[0034] refer to figure 1 , a polymer battery according to the present invention, comprising a battery cell 1, a protective plate 2 connected with the battery cell, and injection molding glue 3 filled between the battery cell and the protective plate. One end of the battery cell connected to the protection board is provided with a protection board storage slot 100 . The storage slot 100 is surrounded by three side walls that are integrally formed higher than the cell body, that is, the cell body 10 is placed in the accommodation cavity formed by the upper panel 11, the left side panel 12 and the right side panel 13, wherein the upper The panel 11 , the left side panel 12 and the right side panel 13 are higher than the cell body 10 , and the three side walls higher than the cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com