A liquid-cooled heat dissipation structure for an ultrasonic motor

An ultrasonic motor, liquid-cooled heat dissipation technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. Complex problems, to achieve the effect of improving heat dissipation efficiency and working stability, increasing cooling effect, and promoting popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

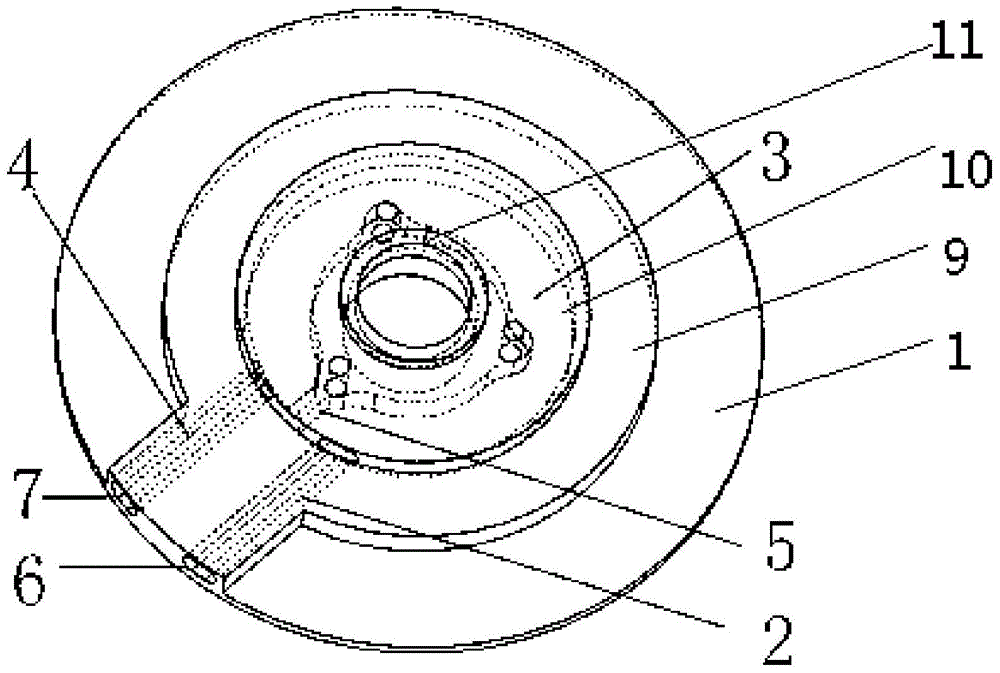

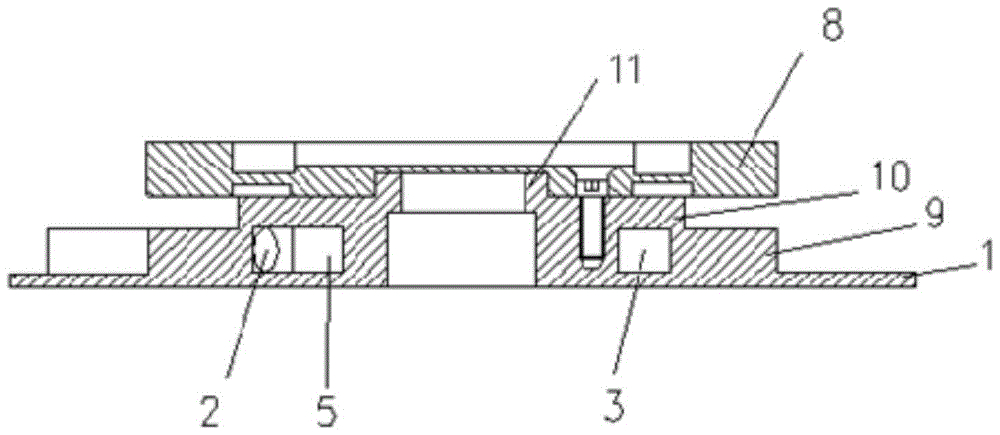

[0028] Such as Figure 1 to Figure 2 as shown, figure 1 It is a perspective view of the cooling base of the heat dissipation structure of the ultrasonic motor of the present invention; figure 2 It is a schematic cross-sectional view of the cooling base of the ultrasonic motor heat dissipation structure and the stator assembly of the ultrasonic motor in the present invention; figure 1 and figure 2 A cooling base of a liquid-cooled heat dissipation structure of an ultrasonic motor and its installation diagram are illustrated, including a cooling base fixedly connected to a stator 8 of an ultrasonic motor, and a cooling inlet channel 2 and a cooling ring are arranged in the cooling base in sequence. Flow channel 3 and cooling outlet channel 4, the opening of the cooling inlet channel 2 on the side wall of the cooling base is a cooling liquid inlet 6, and the cooling outlet channel 4 is on the side wall of the cooling base The opening of the cooling liquid outlet 7; the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com