Miniature impact piezoelectric-drive rotary joint and method for controlling same

A technology of piezoelectric drive and rotary joints, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of low miniaturization, low efficiency, and driving force Insufficient and other problems, to achieve the effect of simple driving mode, stable structure and optimized layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

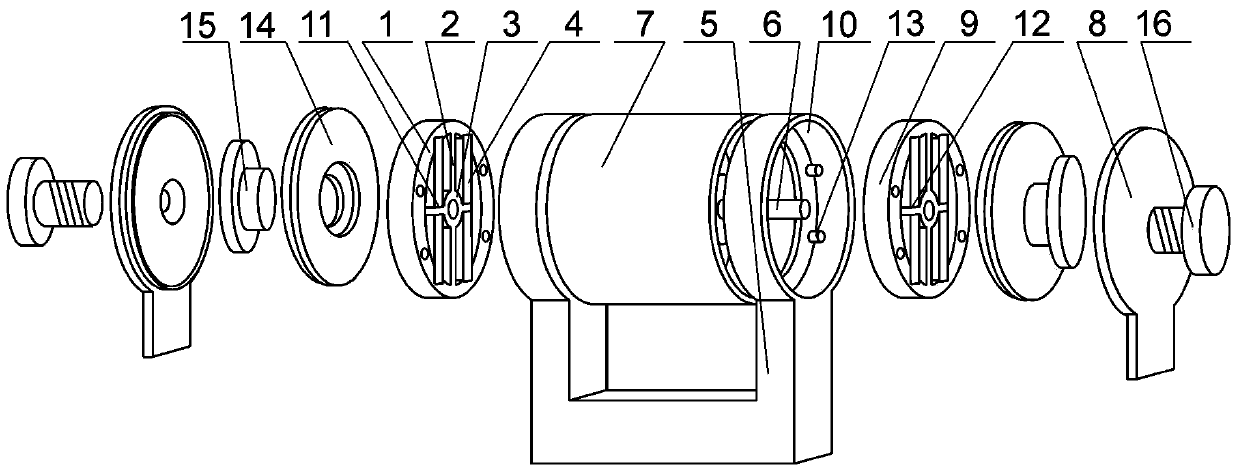

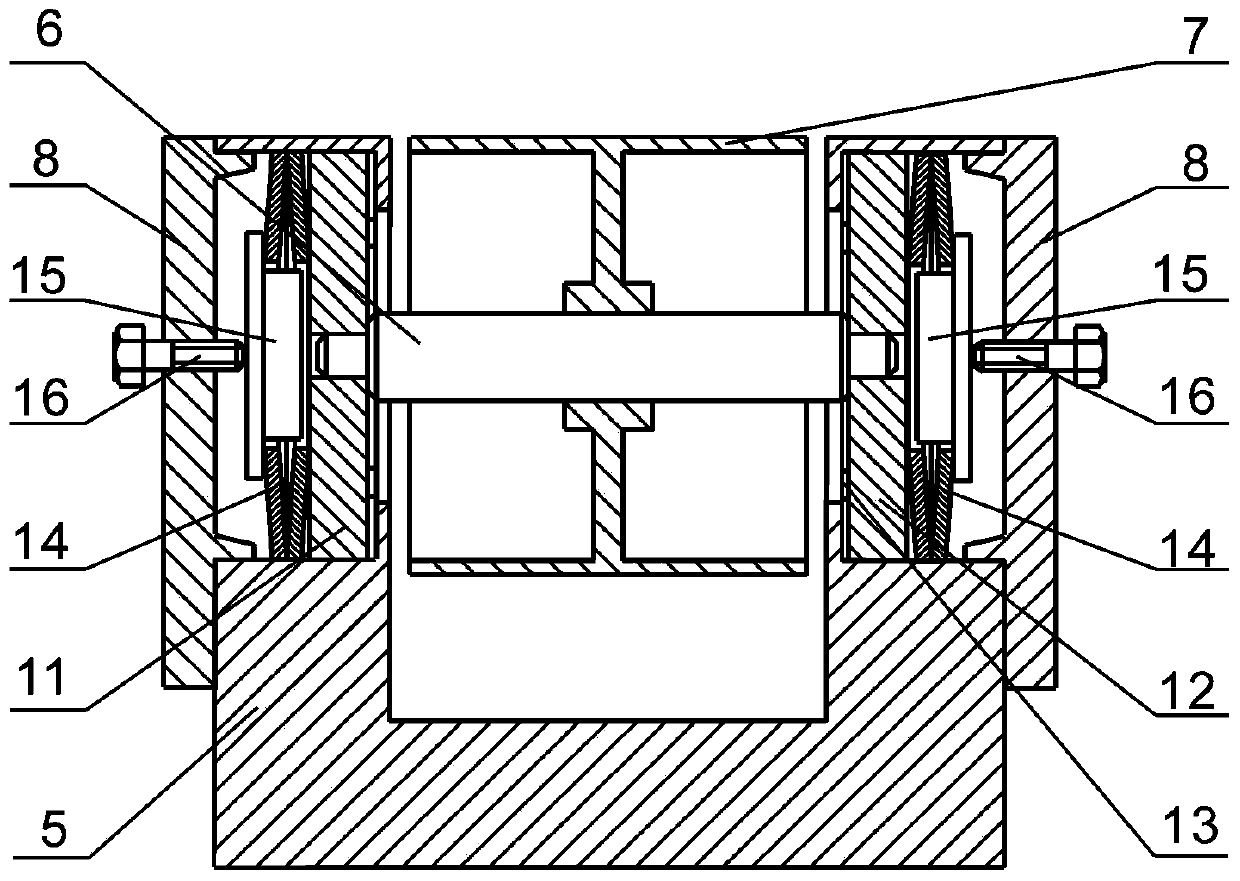

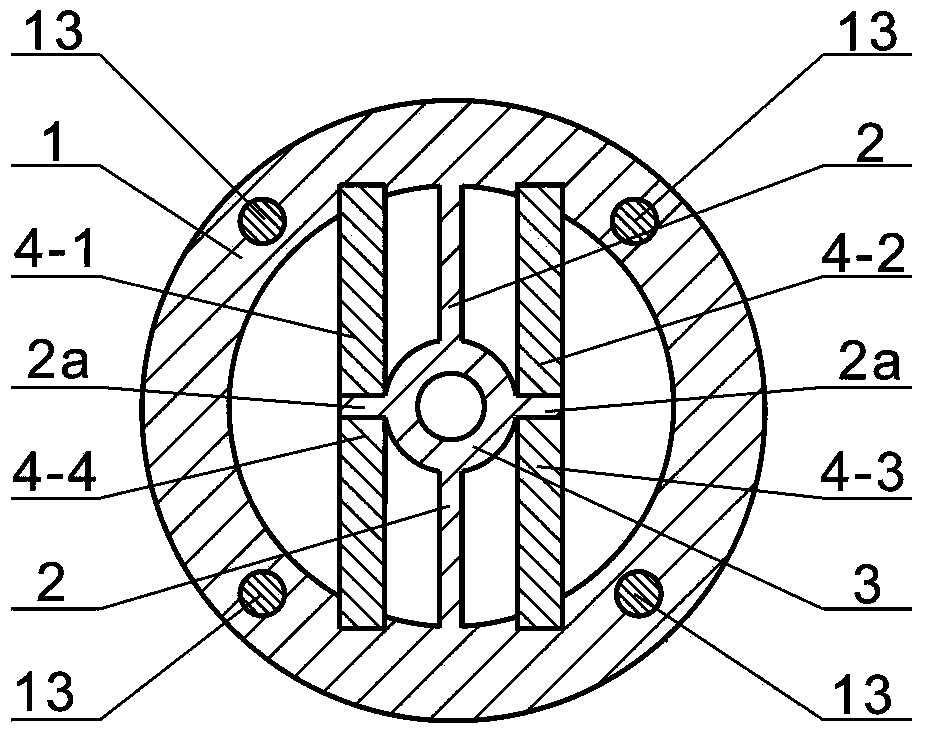

[0027] see figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, the micro-impact piezoelectric-driven rotary joint includes a U-shaped base 5, and a rotating sleeve 7 horizontally clamped in the U-shaped opening on the U-shaped base 5, and the central axis of the rotating sleeve 7 rotates The rotating shaft 6 is installed, and the two ends of the U shape on the U-shaped base 5 are respectively connected with annular seats 10, and the two annular seats 10 are connected to the two ends of the rotating sleeve 7 corresponding to the central axis respectively. Ring-shaped bearing housings 1 are respectively installed in the bearing housing 1. The inner ring wall of the bearing housing 1 is connected with a bearing frame 2 along a certain radial direction. The bearing frame 2 is disconnected at the middle position and connected with a bearing ring 3 in a complete ring. 3 and the bearing seat 1 are the same circle center, on the outer circumferential surface of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com