Photocurable thermosetting composition, method for producing cured product thereof, cured product, and printed circuit board having same

A heat-curable and light-curable technology, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve problems such as difficult to obtain high-definition patterns, achieve excellent storage stability, excellent durability, Excellent manufacturing efficiency and durability

Active Publication Date: 2017-09-22

TAIYO HLDG CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, the screen printing method uses a stencil for the above-mentioned pattern formation and transfers ink with a squeegee, but it is difficult to obtain a high-definition pattern.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

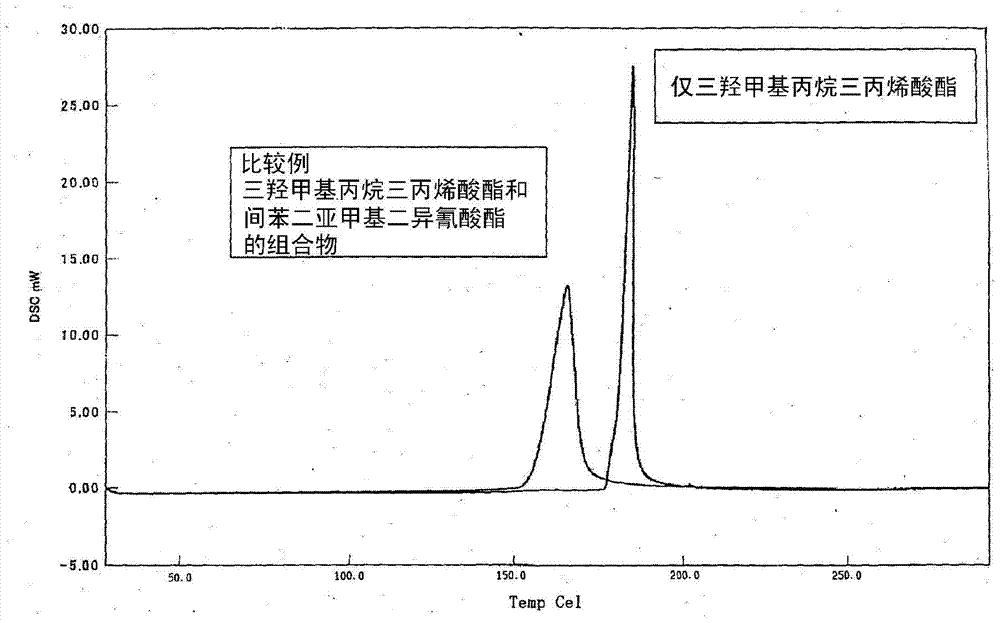

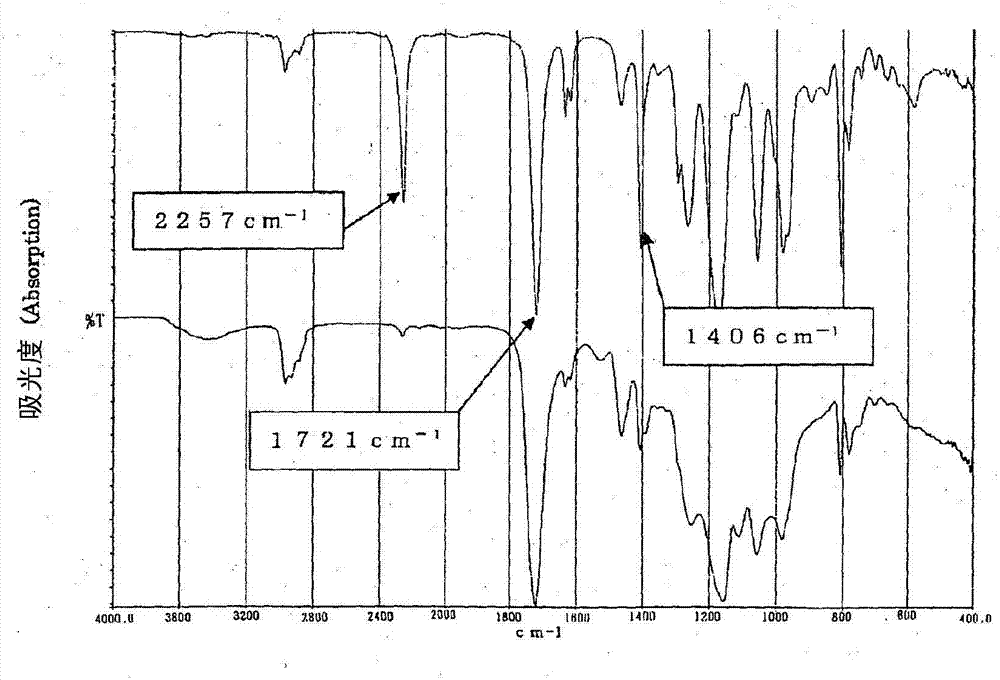

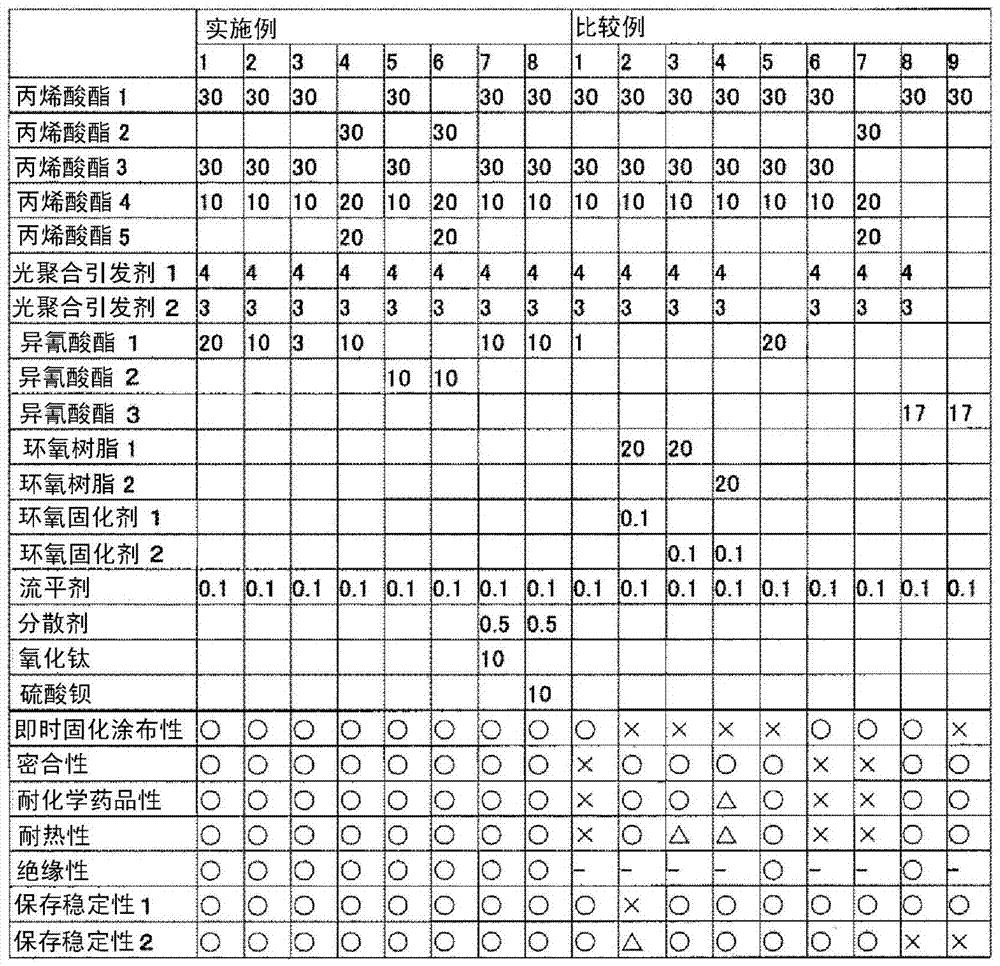

Embodiment 1~8、 and comparative example 1~9

[0115] I. Modulation of Composition

[0116] Each component was mixed in the ratio shown in Table 1, and this was stirred with the dissolver. Regarding Examples 7 and 8, dispersion was further performed with a bead mill, followed by filtration with a 1 μm disc filter. Thus, the composition of this invention and a comparative composition were obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a photocurable thermosetting composition, which has a viscosity corresponding to that suitable for an inkjet printer, can directly draw a pattern on a substrate for a printed circuit board, and can be cured at a relatively low temperature. After curing, it has Excellent adhesion, chemical resistance, heat resistance, and insulation. The present invention provides a photocurable thermosetting composition characterized by containing a (meth)acryloyl group-containing monomer, a blocked isocyanate, and a photopolymerization initiator, and is suitable for printing by an inkjet method.

Description

technical field [0001] The present invention relates to a photo / thermosetting composition, and particularly relates to a photo / thermosetting composition that can be suitably used for printing by an inkjet method. [0002] Furthermore, this invention relates to the manufacturing method of the hardened|cured material obtained using the said photo / heat-curable composition, a hardened|cured material, and the printed wiring board which has a hardened|cured material. Background technique [0003] Conventionally, a photographic development method and a screen printing method have been used to form a resist film, a solder resist film, and a mark of a printed circuit board. [0004] In the photographic development method, a photosensitive resin material and a photomask are applied on a substrate, and exposed to light so that only the part of the photosensitive resin material not covered by the photomask is photocured, and the uncured part is dissolved by a developer solution, thereby...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D11/30B41M5/00C08F2/44H05K3/28

CPCB41M7/009C08F2/48C09D11/101C09D11/322C08F222/102C08F222/103H05K3/287H05K2203/013Y10T428/24802Y10T428/24917B41J2/00C08F220/18C08F222/1006C08G18/62C09D11/107G03C1/498C09D11/30

Inventor 崔城豪志村优之依田健志宇敷滋

Owner TAIYO HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com