Method for Continuously Preparing Core-Shell Phophilic Bipolar Composite Airgel Powder

An airgel particle and core-shell technology, which is applied in the field of airgel, can solve the problems of uneven processing and dispersion, and the decline of heat insulation properties of post-processed products, so as to achieve excellent dispersion and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above and / or other purposes, effects, and features of the present invention more obvious and understandable, the preferred implementation modes are specifically cited below, which are described in detail as follows:

[0031] The continuous preparation technology of the core-shell bipolar airgel powder in the embodiment of the present invention can prepare shell surface hydrophilic-core hydrophobic airgel particles and shell surface hydrophobic-core hydrophilic airgel particles, and The main functions of its preparation method will be clearly presented below.

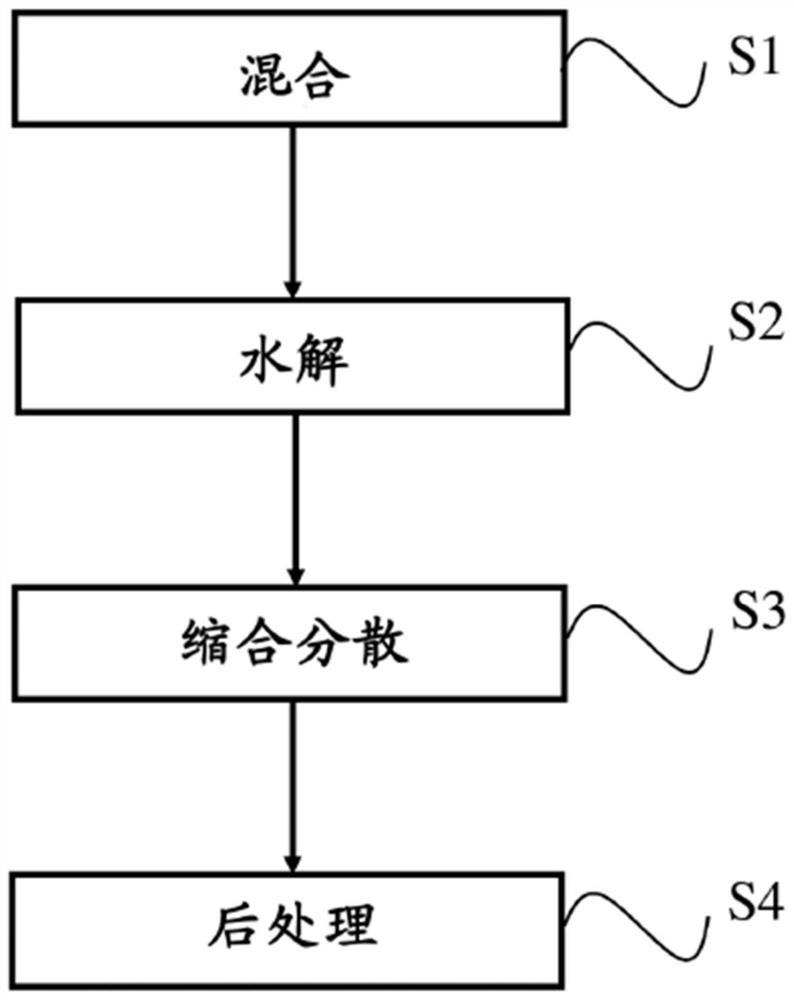

[0032] Please see first figure 1 , which discloses a method for preparing airgel particles according to an embodiment of the present invention, comprising the following steps: a mixing step (S1), a hydrolysis step (S2), a condensation and dispersion step (S3), and a post-processing step (S4).

[0033] Mixing step (S1): The hydrophilic silicon alkoxide compound is one or more substances select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com