Polyester-based composite fiber with excellent thermal insulation and color rendering properties

A composite fiber, thermal insulation technology, applied in the chemical characteristics of fibers, conjugated synthetic polymer rayon, transportation and packaging, etc., can solve the problems of high cost, reduced color rendering, shading, etc. Thermal effect, effect of improving color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

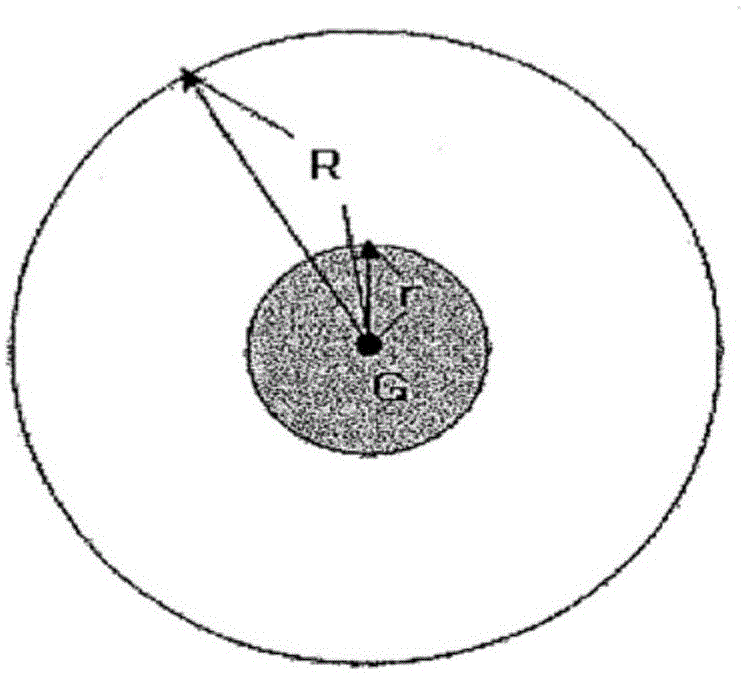

Method used

Image

Examples

Embodiment 1

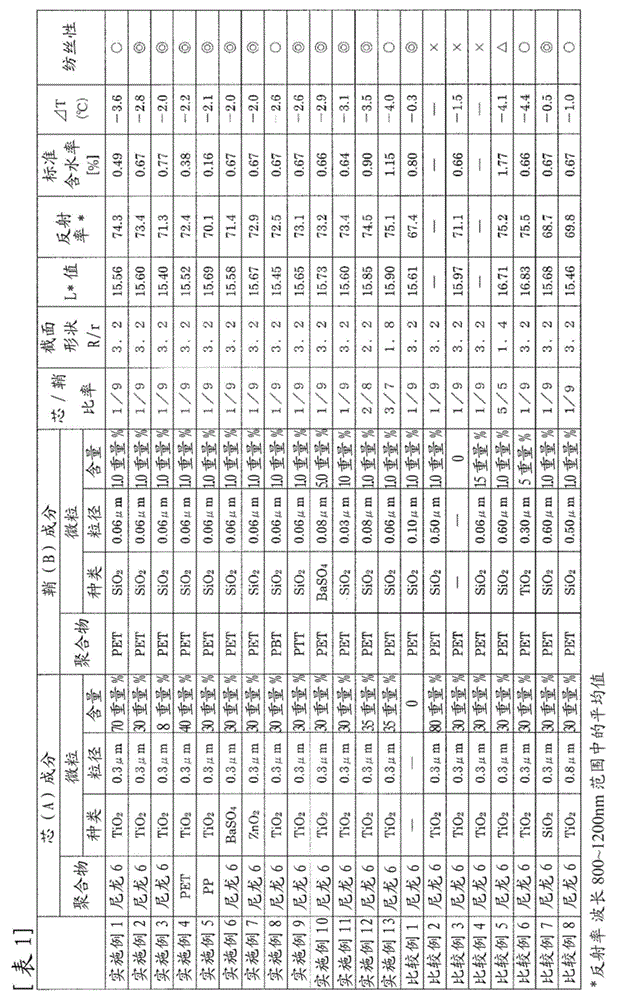

[0106] A polyamide (component A polymer) containing 70% by weight of titanium oxide with an average particle diameter of 0.4 μm in the core component and polyethylene terephthalate (polyethylene terephthalate) containing 1.0% by weight of silica in the sheath component The composite ratio (mass ratio) of component B polymer) is 10:90, using a nozzle with 24 holes (hole diameter 0.25mmφ), spinning temperature 260°C, single hole discharge amount = 1.42g / Spinning in minutes, blow the cooling air with a temperature of 25°C and a humidity of 60% at a speed of 0.4m / s to the spun filaments, and after the filaments are below 60°C, they are introduced to a position 1.2m below the spinning nozzle The length is 1.0m, the diameter of the inlet guide rod is 8mm, the diameter of the outlet guide rod is 10mm, and the inner diameter is 30mm. The strips were oiled and wound by two take-off rolls at a speed of 4000 m / min to obtain 84T / 24f composite fiber filaments (strength 2.53cN / dtex, elonga...

Embodiment 2~11

[0108] The polymers of components A and B, the added particles and content of components A and B were changed, and spinning was carried out in the same manner as in Example 1 to obtain the 84T / 24f conjugated fiber yarn. Table 1 shows the physical properties of the obtained fibers. All of them had good L* value and ΔT, and were of quality without any problem. In addition, in Example 10, by using barium sulfate as the fine particles contained in the sheath component, a high heat-shielding effect can be obtained while maintaining the color rendering property. In addition, the color fastness to washing and color fastness to light of any fiber are above grade 4.

Embodiment 12~13

[0110] The core-sheath ratio of this conjugate fiber was changed, and it spun by the same method as Example 1, and obtained this conjugate fiber filament of 84T / 24f. All exhibited excellent thermal insulation properties and color rendering properties, and were of quality without any problem. In addition, the fastness to washing and the fastness to light of any fiber were all grade 4 or higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com