A method of creating a frictional washing surface

A surface bonding, part-of-a-kind technology applied in the field of constructing friction-cleaning surfaces that is time and cost efficient, eliminates manufacturing steps, and reduces time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

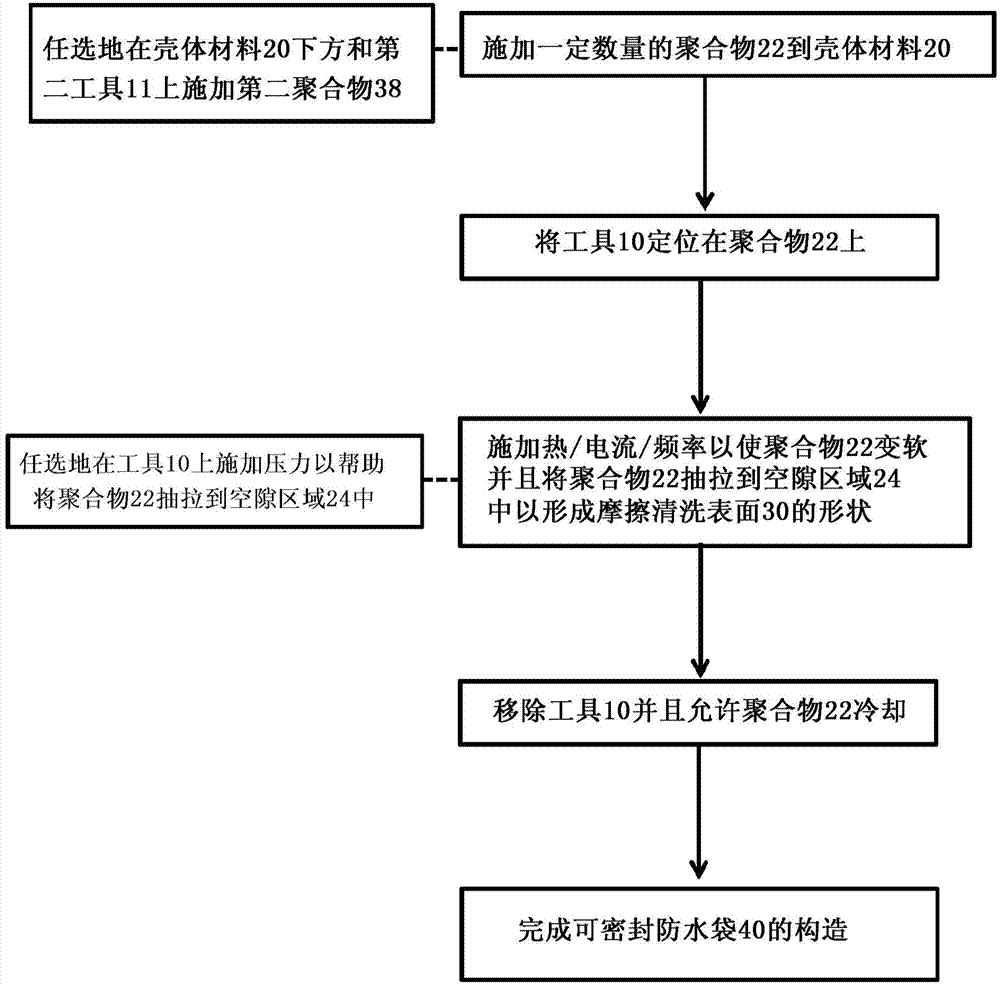

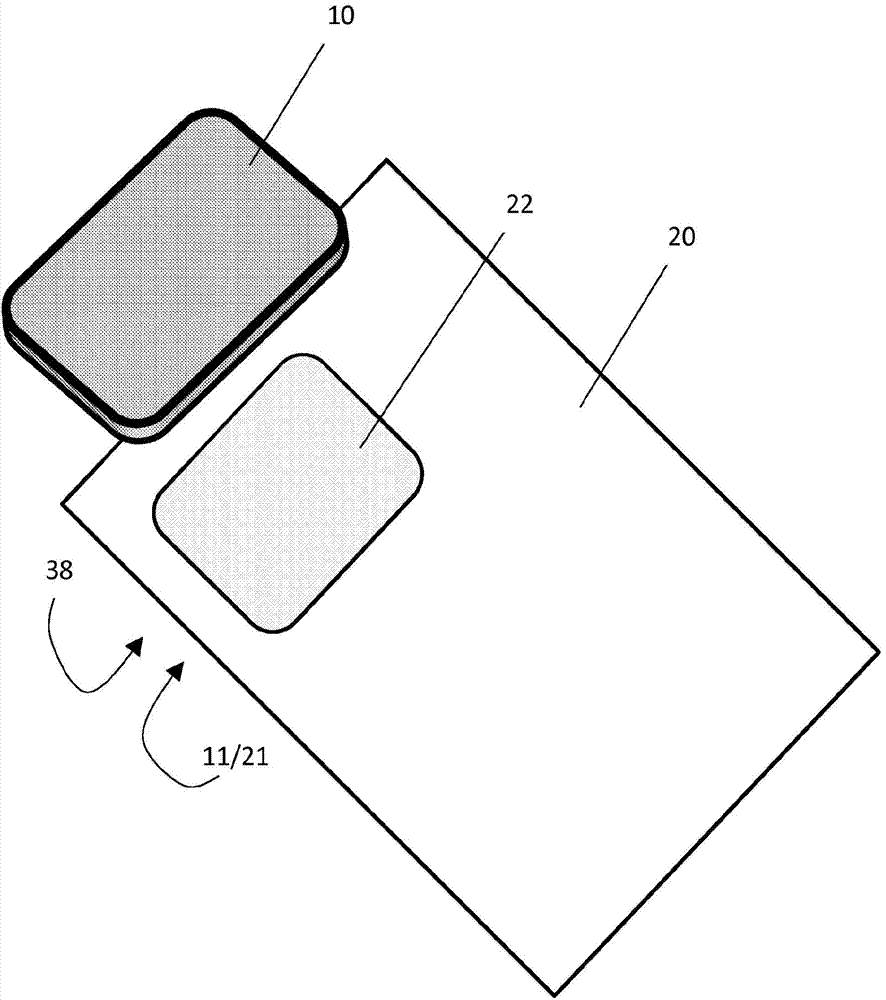

[0047] Such as figure 1 Shown: a certain amount of polymer 22 is applied to the housing material 20; the tool 10 is positioned on the polymer 22; heat and / or current and / or high frequency are applied to soften the polymer 22 and pump it Pull into the void area 24 of the tool 10 to form the shape of the abrasive cleaning surface 30; the tool 10 is removed and the polymer 22 is allowed to cool; construction of the sealable waterproof bag 40 can then be completed. Optionally, a second polymer 38 may be applied underneath the housing material 20 and on the second tool 11 to allow a gripping surface 48 to be formed on the housing material 20 to support the formed abrasive cleaning surface 30 . Also optionally, pressure may be applied to tool 10 to assist in drawing polymer 22 into void region 24 .

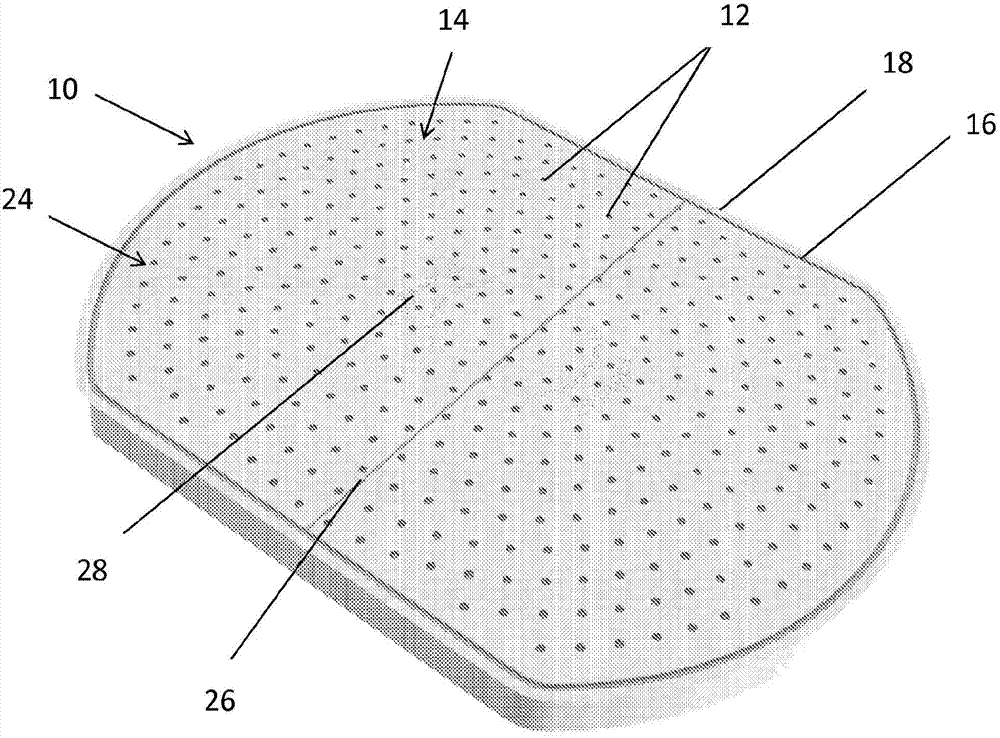

[0048] At this point will refer to figure 2 One embodiment of the present invention is described with reference to the diagram shown in FIG. 3 .

[0049] figure 2 The tool 10 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com