A method for preparing sauce base using soy sauce tailings and a brewing and drying device

A technology for tailings and soy sauce, applied in the field of sauce base preparation, can solve problems such as waste, long fermentation period, environmental pollution, etc., and achieve the effects of saving energy and production cost, simple operation and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

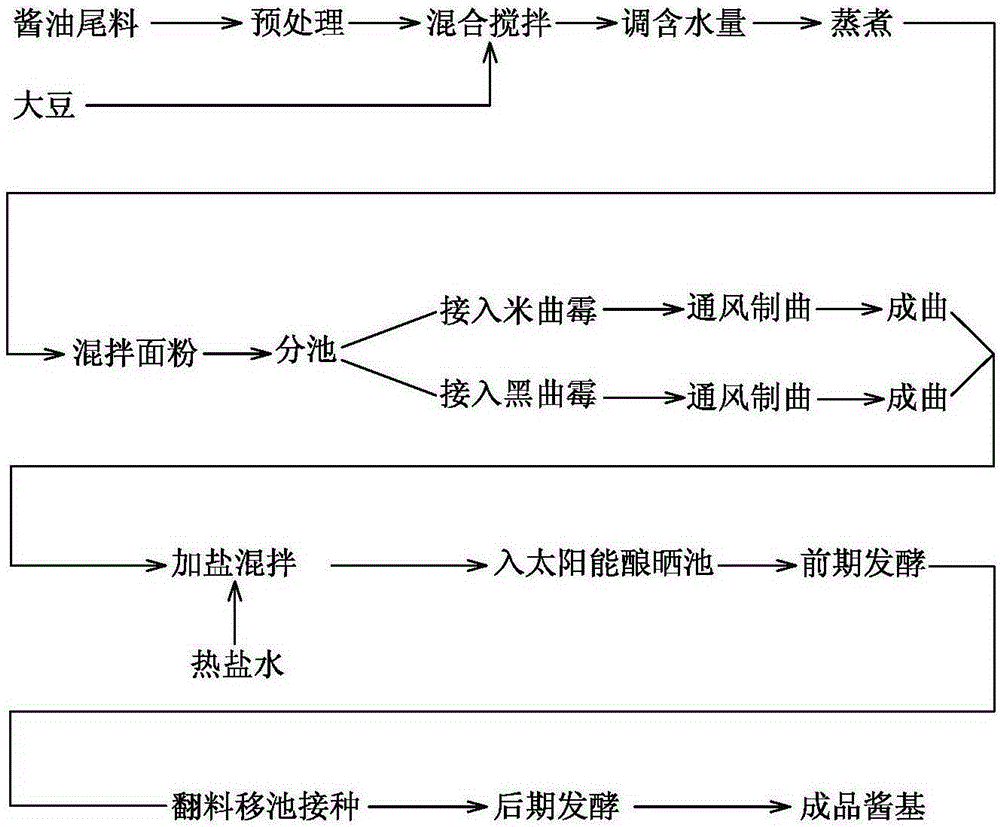

[0030] Embodiment one: a kind of method utilizing soy sauce tailings to prepare sauce base, comprises the steps:

[0031] (1) Carry out heating pretreatment to the tailings of soy sauce, let it stand for cooking, the temperature and pressure are 2 kg, the temperature is 131° C., and the pressure is maintained for 5 minutes.

[0032] (2), mixing and stirring the pretreated soy sauce tailings and soybeans to obtain a mixture, wherein the soy sauce tailings account for 45wt%, and soybeans account for 55wt%;

[0033] (3), water is added to the mixture until the water content is 45wt%, and then put into a high-pressure cooking pot for cooking, after reaching a pressure of 2KG, keep the pressure for 5 minutes, and quickly exhaust and reduce the pressure;

[0034] (4) Stir and mix the steamed mixture with flour, and then divide it into two parts, A and B, wherein flour accounts for 5 wt%, and the ratio of material A to material B is 7:3.

[0035] (5), insert Shanghai brewing 3.042 A...

Embodiment 2

[0038] Embodiment two: a kind of method utilizing soy sauce tailings to prepare sauce base, comprises the steps:

[0039] (1) Carry out heating pretreatment to the tailings of soy sauce, let it stand for cooking, the temperature and pressure are 2 kg, the temperature is 131° C., and the pressure is maintained for 5 minutes.

[0040] (2), mixing and stirring the pretreated soy sauce tailings and soybeans to obtain a mixture, wherein the soy sauce tailings account for 50wt%, and soybeans account for 50wt%;

[0041] (3), water is added to the mixture until the water content is 45wt%, and then put into a high-pressure cooking pot for cooking, after reaching a pressure of 2KG, keep the pressure for 5 minutes, and quickly exhaust and reduce the pressure;

[0042] (4) Stir and mix the cooked mixture with flour, and then divide it into two parts, A and B, wherein flour accounts for 5wt%, and the ratio of material A to material B is 6.5:3.5.

[0043] (5), insert Shanghai brewing 3.042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com