Spray nozzle with spray area adjusting function

A spray area, adjustable technology, applied in spray devices, spray devices, etc., can solve the problem that adjustable nozzles are not suitable for spray devices with larger spray diameters, and achieve stable and reliable cooperation, stable cooperation, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

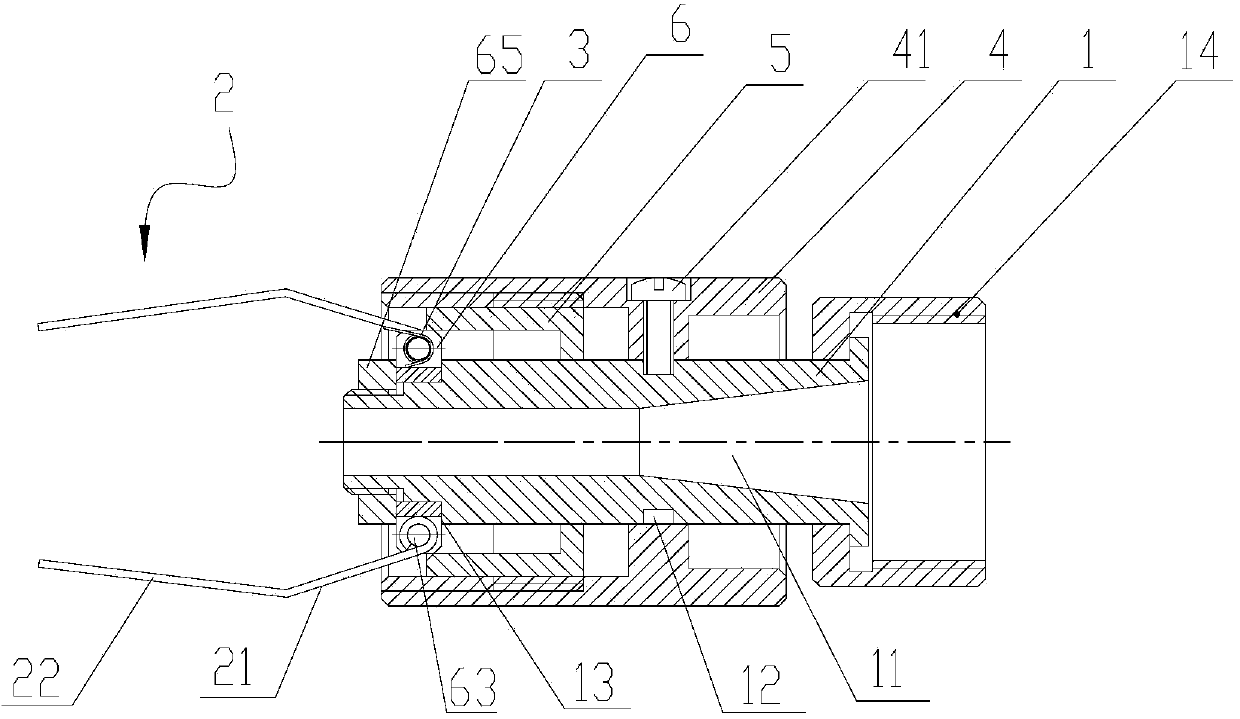

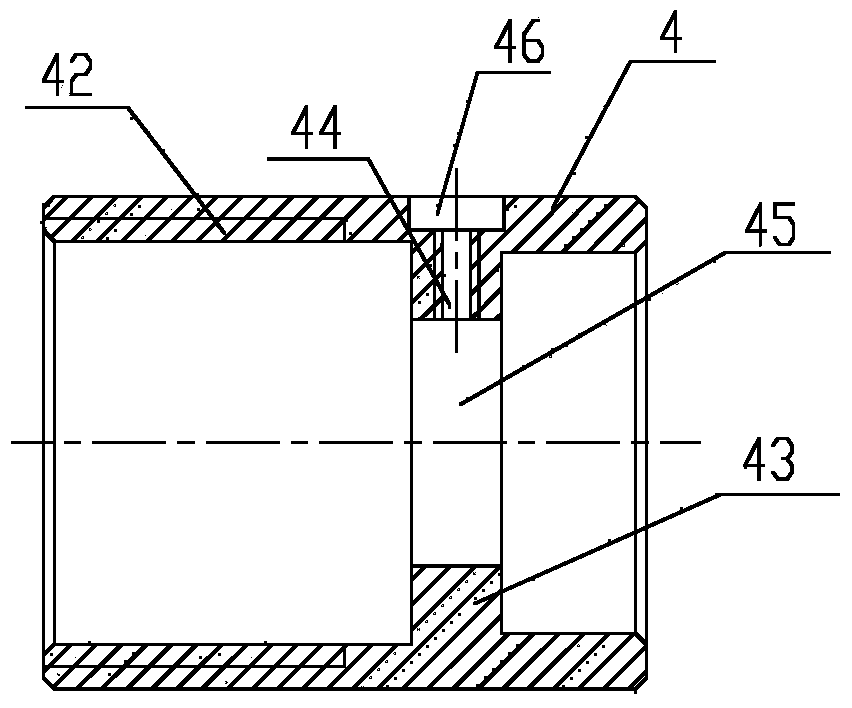

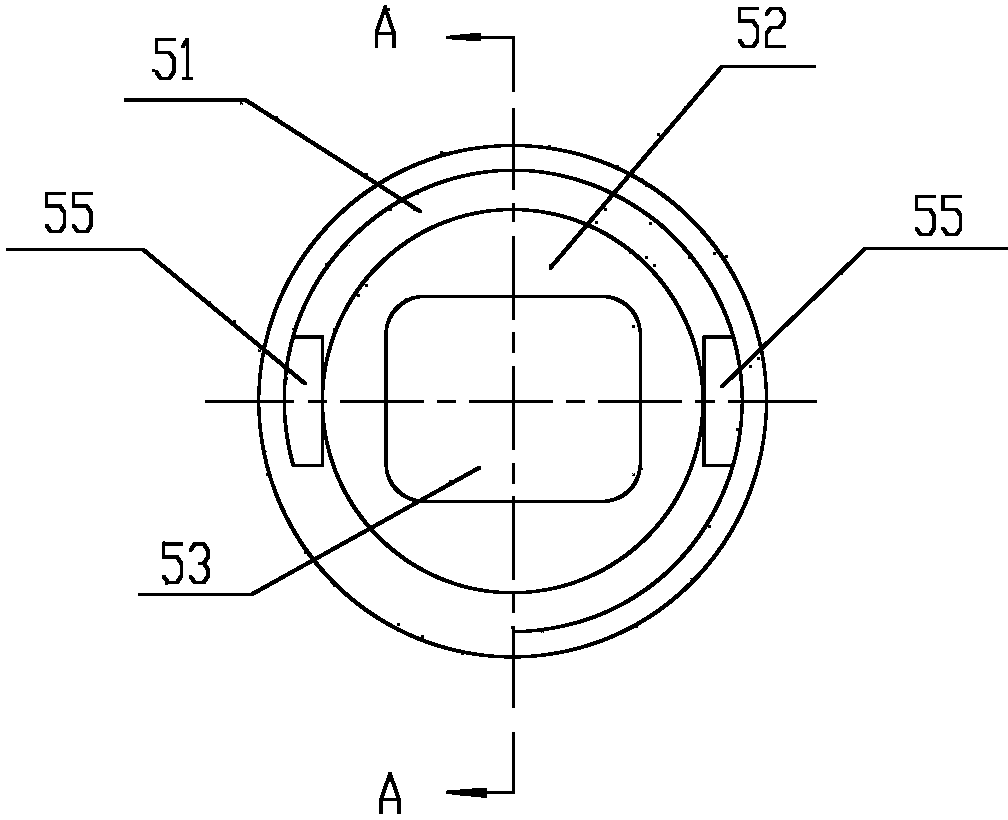

[0037] figure 1 It is a schematic cross-sectional view of a nozzle with adjustable spray area according to an embodiment of the present invention. like figure 1 As shown, the nozzle with adjustable spray area of the present invention includes a nozzle body 1, at least two baffles 2, an elastic member 3 for exerting external force on the baffles 2, an outer adjustment member 4 sleeved on the nozzle body 1, and an inner adjustment Piece 5.

[0038] The nozzle body 1 has a nozzle cavity 11 that allows fluid to pass through and to be ejected forward. The blocking piece 2 is hinged with the front end of the nozzle body 1 through the hinge shaft 63. In this embodiment, the rear end of the blocking piece 2 is hinged with the nozzle body 1 through the hinge shaft 63, and the blocking piece 2 can be directly hinged on the nozzle body. 1, it can also be hinged on the part fixed with the nozzle body 1. The preferred solution will be described later. Each of the baffles 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com