A defect detecting device for a bottle cap

A defect detection and bottle cap technology, applied in the direction of optical testing defects/defects, sorting, etc., can solve the problems of difficult to solve the problems of human fatigue and false detection, low sampling frequency, low work efficiency, etc., to improve the detection speed and detection efficiency. The effect of reliability, time delay reduction, labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

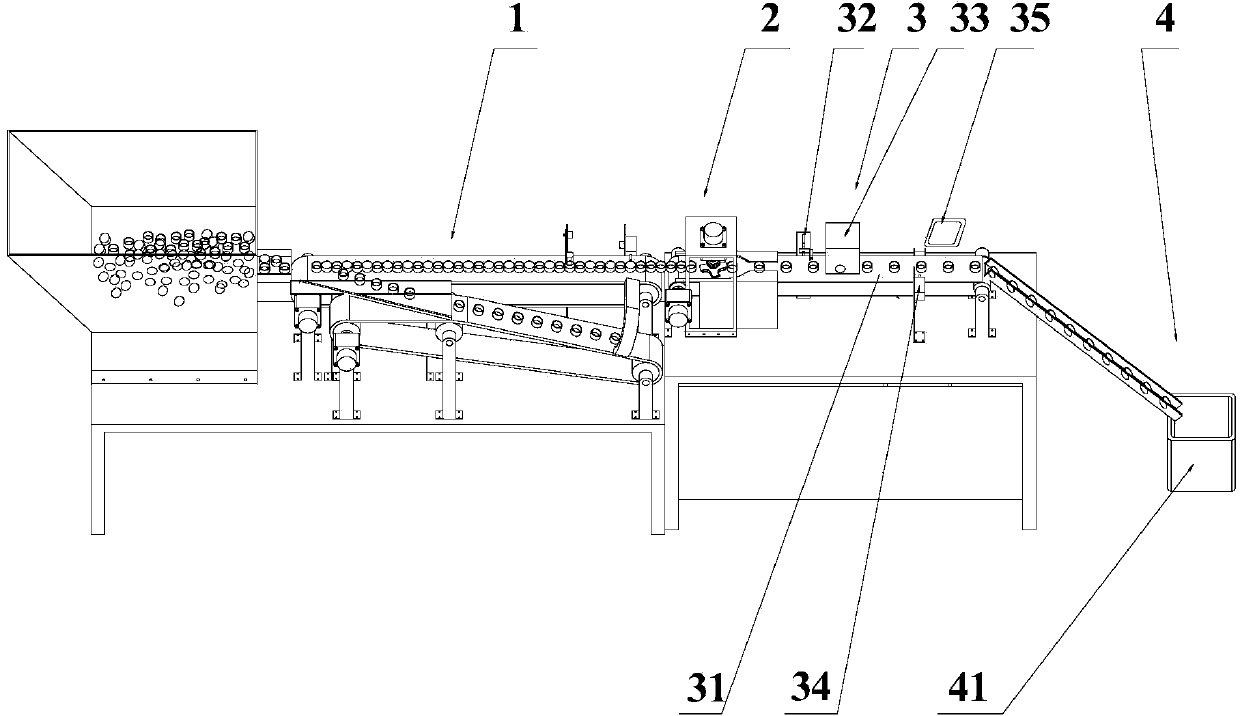

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a bottle cap defect detection device, which includes a finishing material facing feeding mechanism 1, a material gap position adjusting mechanism 2, a detection and screening mechanism 3 and a receiving mechanism 4 arranged in sequence on the frame;

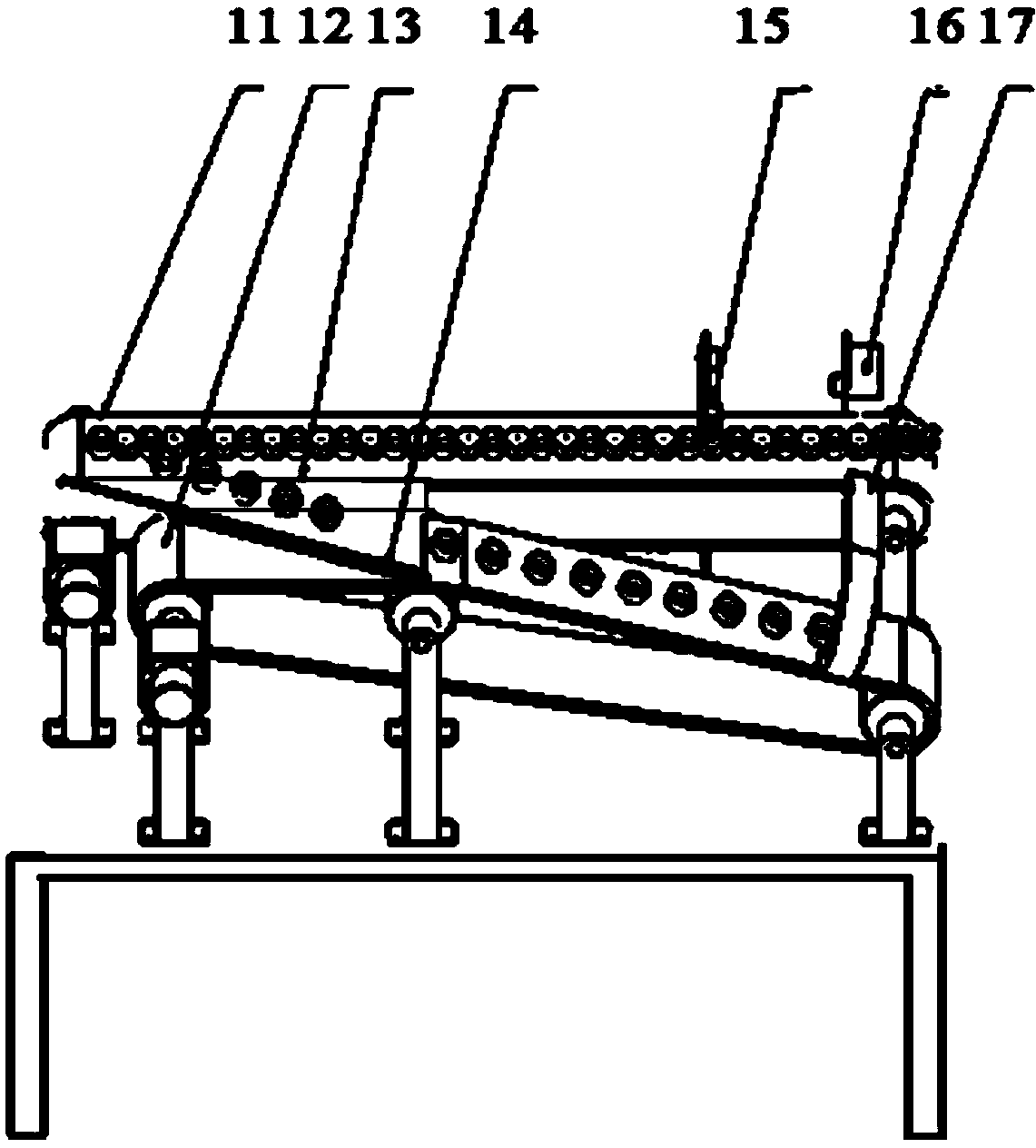

[0028] The feeding mechanism 1 for sorting materials includes a vibrating hopper, a conveyor belt and an overturning mechanism 17 arranged on the frame. The vibrating hopper is arranged at the left end of the support. Overturn mechanism 17;

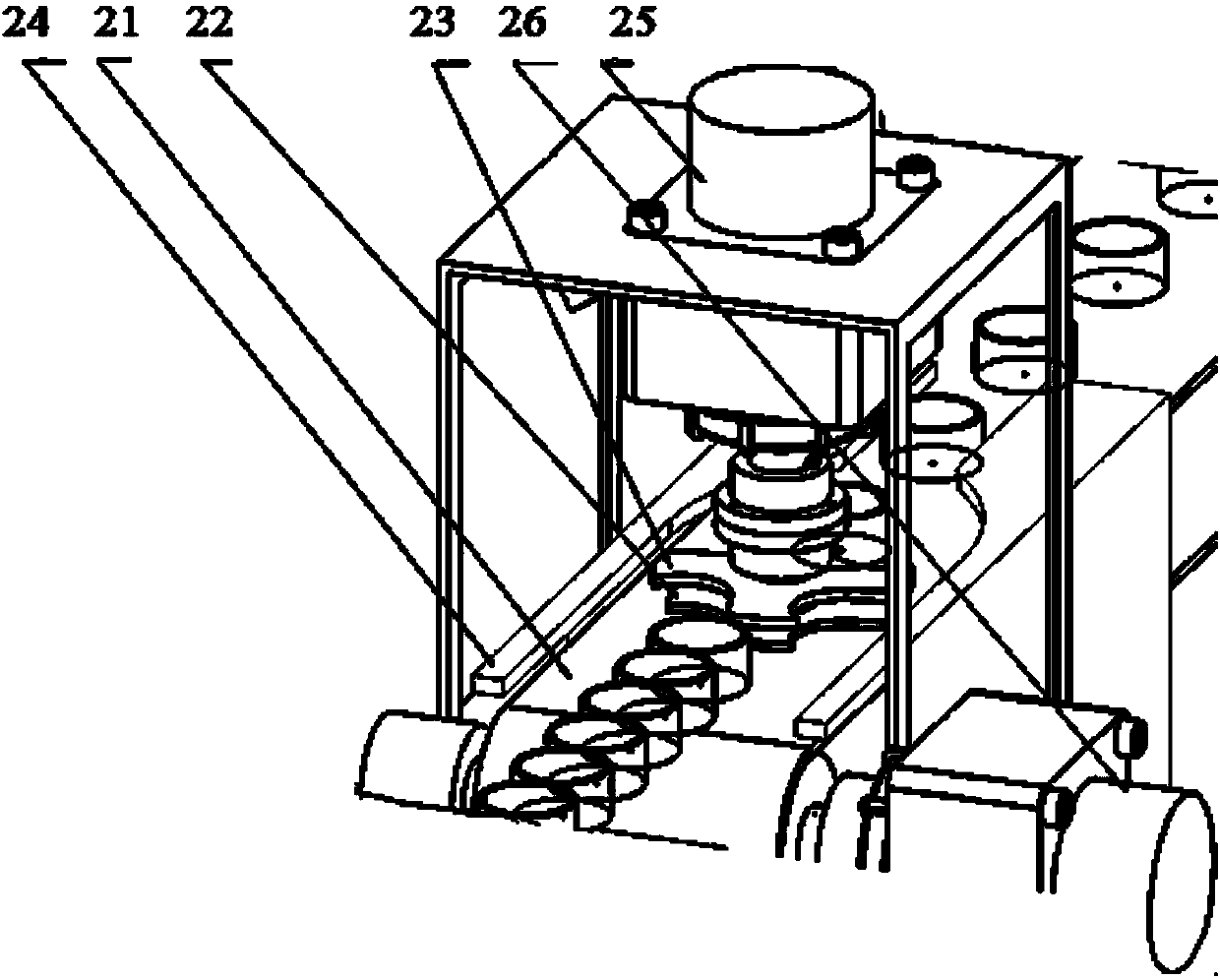

[0029] The mechanism 2 for adjusting the material gap position includes a first conveyor belt 21 for receiving the end of the feeding conveyor belt 11, a gap disc, a limit mechanism, a motor one 25 and a motor two 26, and a gap circle is arranged directly above the conveyor belt 21. disc, the notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com