A repair welding method and device for large involute spur gears

A technology of large gears and involutes, applied in auxiliary devices, belts/chains/gears, welding equipment, etc., can solve problems such as unsubmitted repair welding methods and devices, achieve efficient and accurate repair welding, improve utilization, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

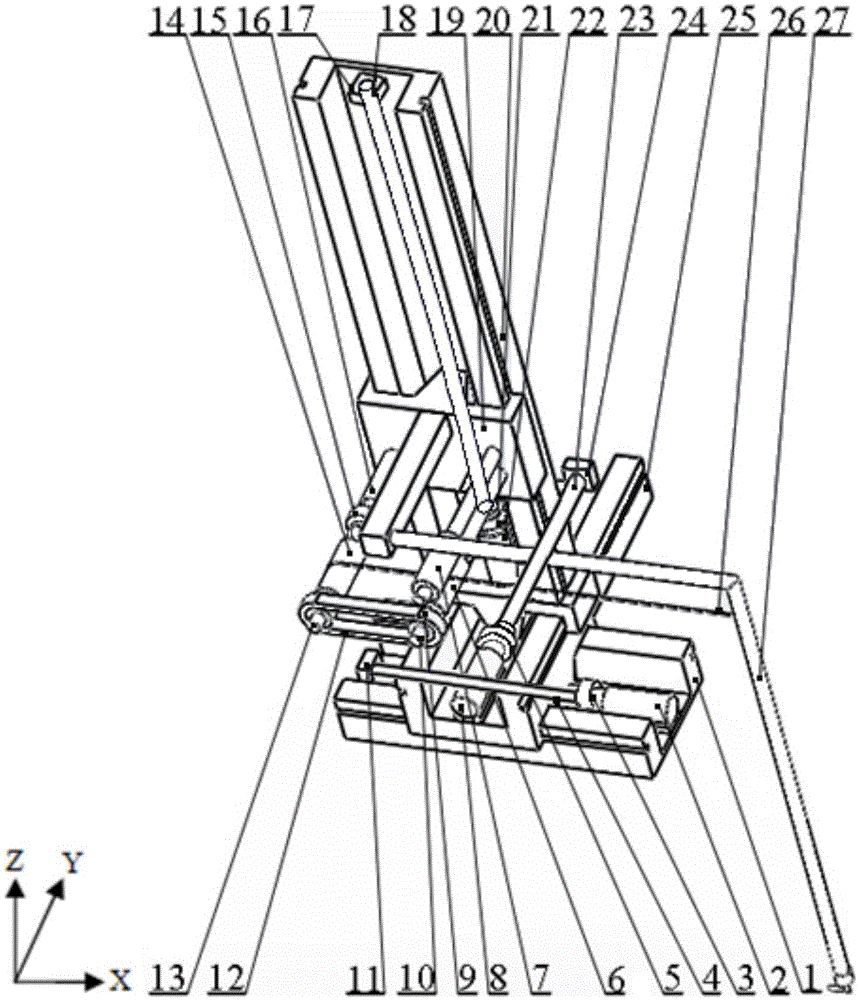

[0014] like figure 1 and figure 2 As shown, a large involute spur gear repair welding method and its device, using Siemens' S7-200 software and V4.0STEP7-Micro / WIN software, and the CPU224 in the S7-200 series PLC as the control system, To control the repair welding device, the steps of repair welding are as follows:

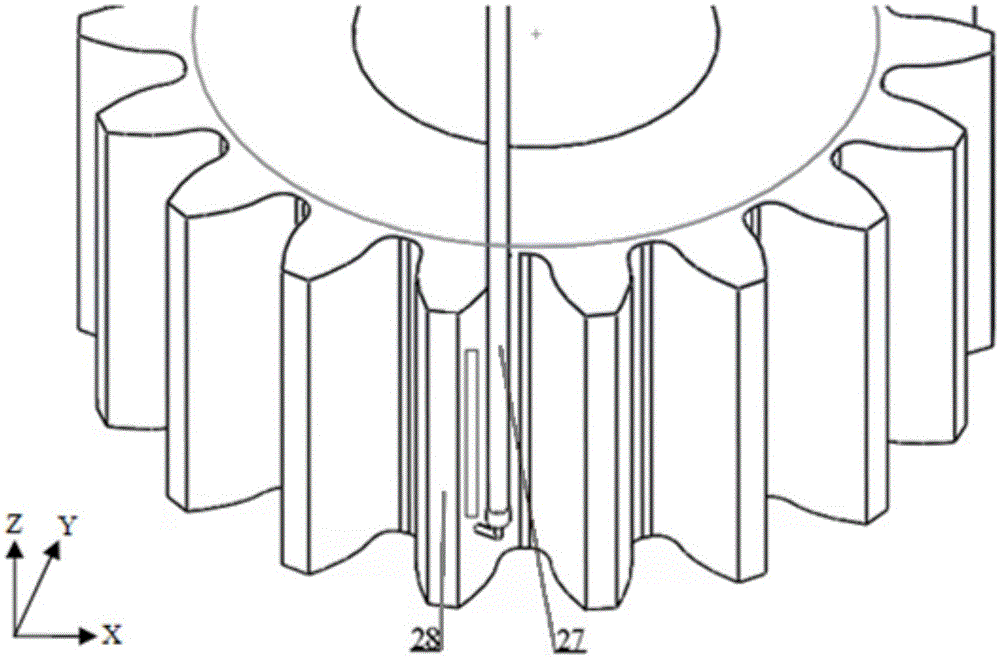

[0015] a. Place and fix the worn large gear 28 horizontally, then place the repair welding device on the worn large gear 28, and position it through the shaft hole of the worn large gear 28;

[0016] b. After the repair welding device is positioned, the motor 2 on the X-axis in the device drives the X-axis screw 4; the motor 8 on the Y-axis drives the Y-axis screw 23; the motor 22 on the Z-axis drives the Z-axis screw 18, through The common linear motion of the X-axis screw 4, the Y-axis screw 23 and the Z-axis screw 18 positions the welding torch 27 to the worn part of the large gear;

[0017] c. After the welding torch 27 is positioned, the motor 22 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com