Simple polishing machine for the production of piano shell parts

A technology for parts and polishing machines, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc. High work efficiency and good workpiece surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

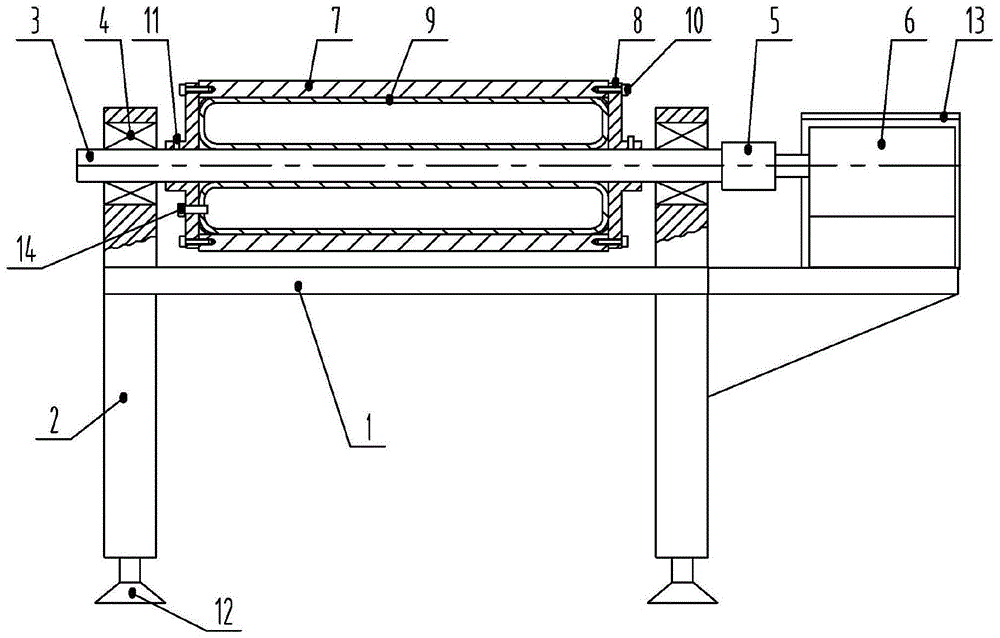

[0031] see figure 1 , in the figure, the present invention is used for the simple polishing machine of piano shell parts production, comprises workbench 1, and four corners of the bottom of workbench are provided with outrigger 2, and polishing roller is installed above the workbench, and the two ends of polishing roller pass bearing and bearing seat 4 Rotate and support on the workbench, and one end of the polishing roller is directly connected with the driving motor 6 through the shaft coupling 5, the polishing roller includes the rotating shaft 3 and the roller body 7, and the two ends of the roller body are fixedly provided with end caps 8. An airtight chamber is formed between the body, both end covers and the rotating shaft, and an annular air bag 9 is arranged in the airtight chamber, and an air nozzle 14 is arranged on the air bag, and the air nozzle protrudes from the end cover, and the air bag completely fills the entire airtight chamber when it is full of air , the ...

Embodiment 2

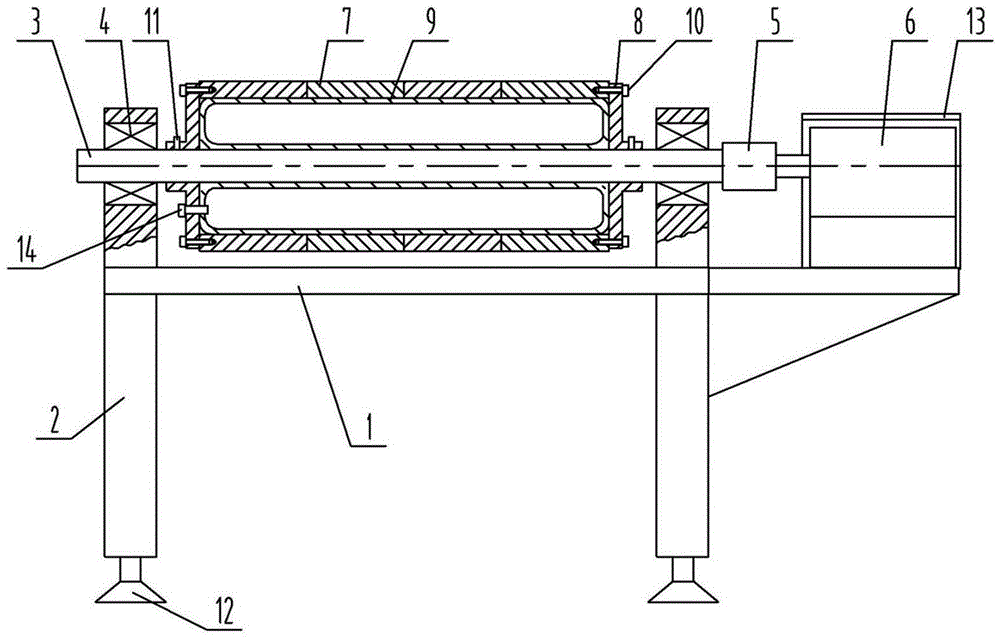

[0035] see figure 2 , Figure 4 , the structure of this embodiment is similar to that of Embodiment 1, and the same numbers in the figure represent the same meaning, which will not be repeated here. The difference is that the roller body described in this embodiment is composed of multiple sections connected in series; Screw connection between.

[0036] Compared with Embodiment 1, the roller body of this embodiment is composed of multiple sections connected in series. According to the width of the workpiece to be processed, the length of the roller body can be adjusted accordingly, so as to prevent the length direction of the surface of the roller body from being too long due to unused places, which will affect the operation of workers. , so it is more convenient to use.

Embodiment 3

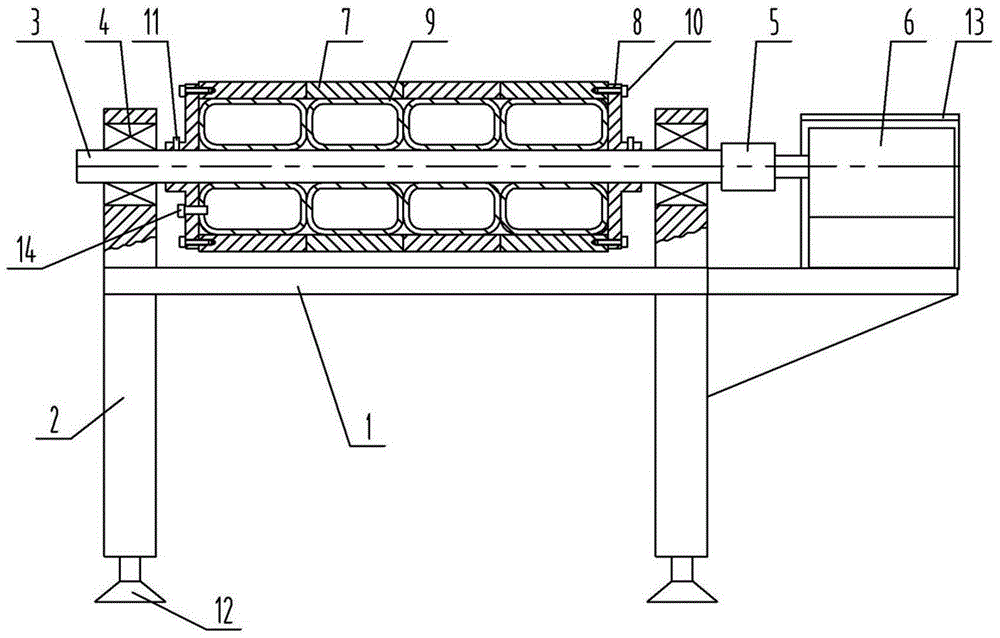

[0038] see figure 2 , Figure 5 , the structure of this embodiment is similar to that of Embodiment 2, and the same numbers in the figure represent the same meaning, which will not be repeated here. Teeth and matching grooves snap together.

[0039] Compared with Embodiment 2, when the segmented roller bodies of this embodiment are connected in series, two adjacent segments are locked together by a plurality of protruding teeth uniformly distributed on the end surfaces and matching grooves. The realized functions are the same, only the specific means of implementation are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com