Assembly structure of front end framework of automobile skylight framework

A front-end frame and car sunroof technology, which is applied to vehicle parts, transportation and packaging, roofs, etc., can solve the problems of low work efficiency, time-consuming assembly, time-consuming and labor-intensive problems, and achieve the effect of convenient assembly and splicing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

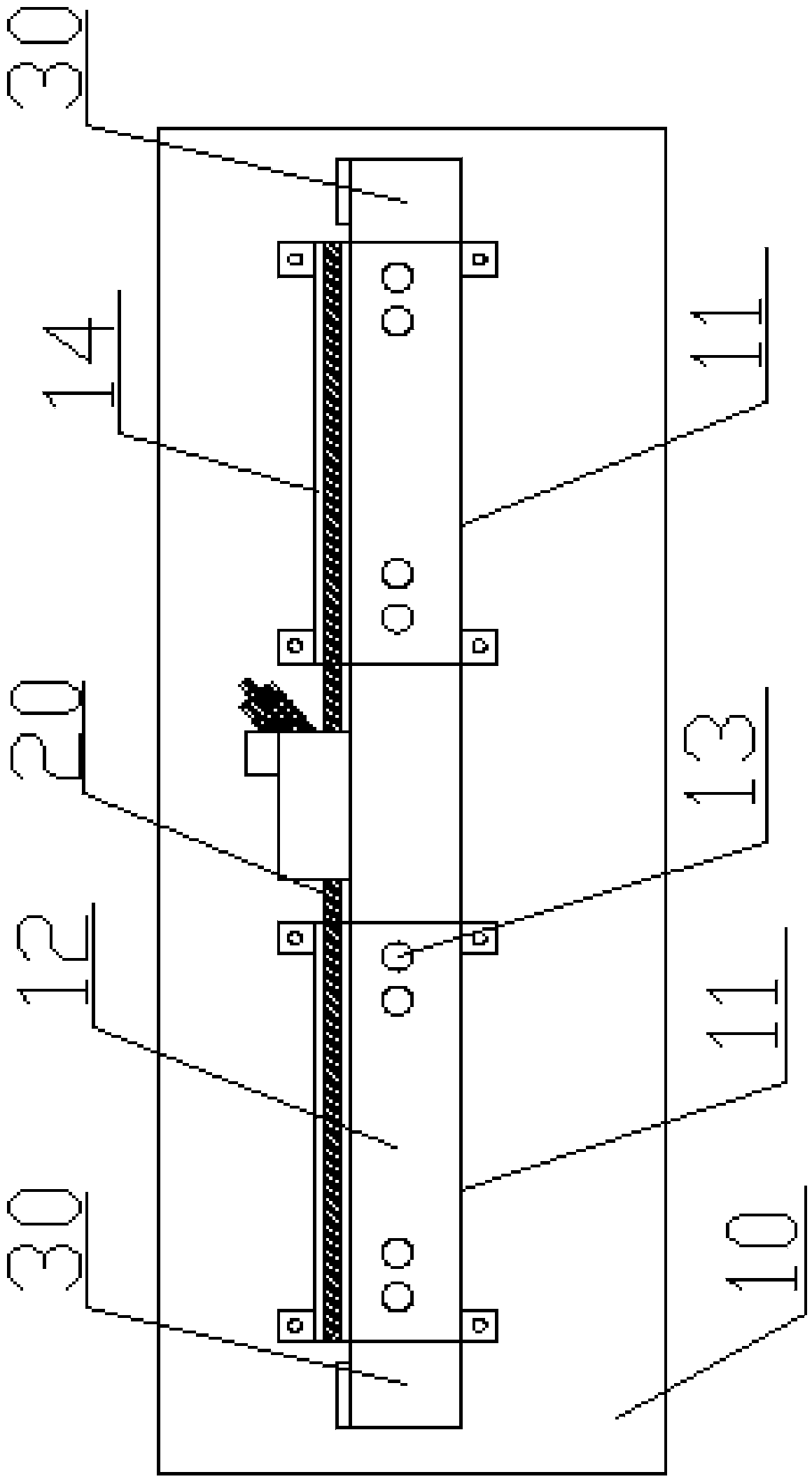

[0012] The invention provides a front-end frame assembly structure of an automobile sunroof frame, such as figure 1 As shown, it includes a workbench (10), a motor copper pipe (20) and a front frame (30), and two rectangular parallelepiped rubber cushions (11) of the same size are fixed by bolts on the side of the workbench (10) near the side. , the two rectangular parallelepiped rubber cushions (11) form a straight shape, the gap width of the two rectangular parallelepiped rubber cushions (11) is greater than the motor width of the front frame (30), and the two rectangular parallelepiped rubber cushions (11) are set There are grooves (12) for cooperating with the front-end frame (30), and the two rectangular rubber pads (11) are provided with round holes (13) for cooperating with the front-end frame (30) bolts.

[0013] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com