Four-degree-of-freedom inner rotor magnetic bearing

An inner rotor and magnetic bearing technology, applied in the field of non-contact magnetic suspension bearings, can solve the problems of complex circuit, poor stability, low damping, etc., and achieve the effects of high control accuracy, low rotational power consumption, and small magnetic field fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

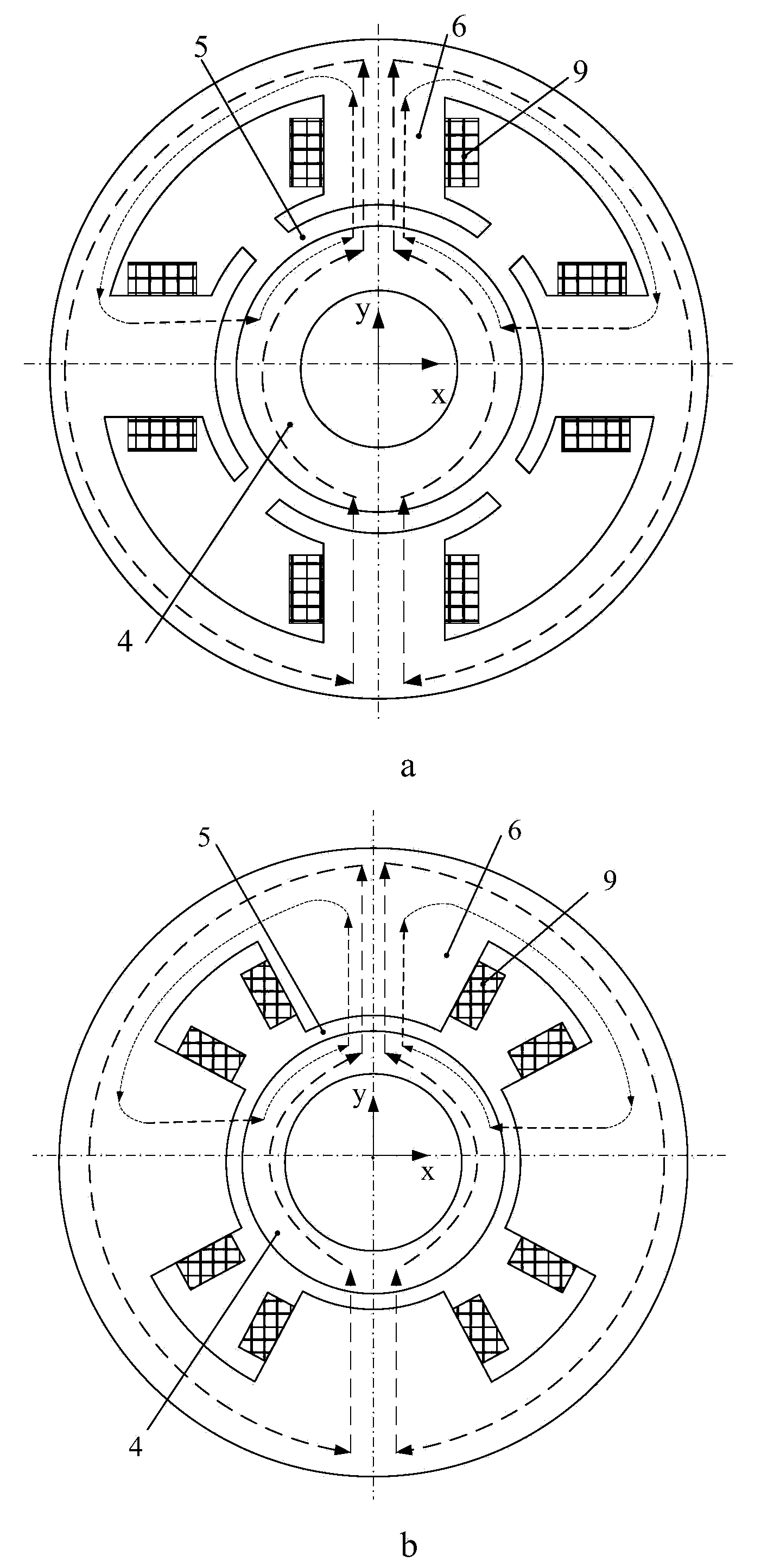

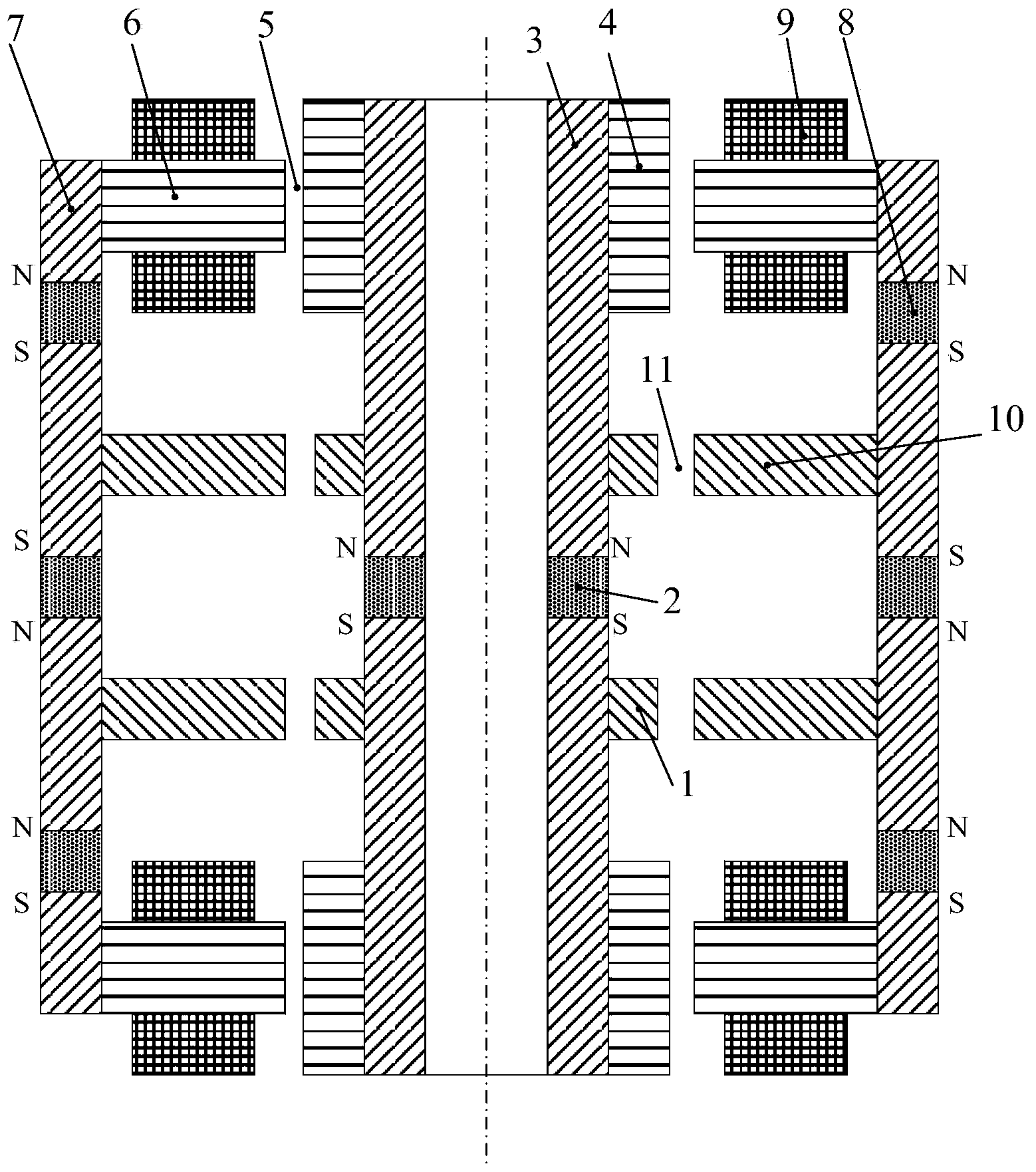

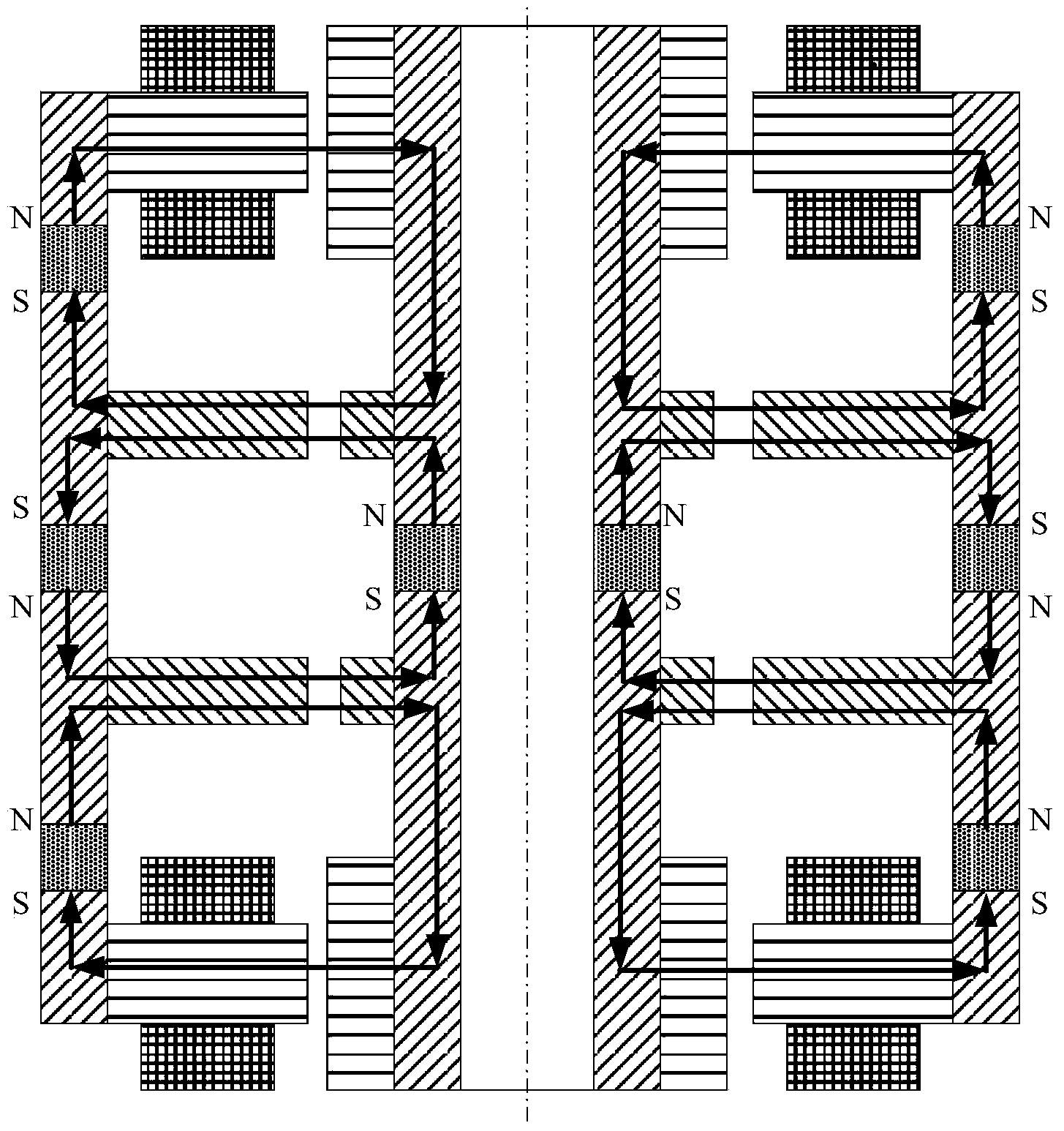

[0017] like figure 1 As shown, a four-degree-of-freedom inner rotor magnetic bearing consists of a passive part inner rotor magnetic ring 1, an inner rotor permanent magnet 2, an inner rotor magnetic body 3, an inner rotor core 4, an air gap 5, a stator core 6, and a stator guide The magnetic ring 7, the stator permanent magnet 8, the coil 9, the passive part of the stator magnetic ring 10 and the passive part of the air gap 11, wherein each stator core 6 is composed of 4 magnetic poles, and two stator cores 6 form the upper and lower ends of the magnetic bearing 8 magnetic poles respectively form the magnetic poles in the positive and negative directions of the X and Y axes. A coil 9 is wound on the magnetic pole of each stator core 6. The inside of the stator core 6 is the inner rotor core 4, and the inside of the inner rotor core 4 is the inner rotor magnetizer. 3. There is a certain gap between the outer surface of the inner rotor core 4 and the inner surface of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com