An electronically controlled two-way three-state clutch

A clutch and electronic control technology, applied in the field of mechanical transmission, can solve problems such as complex clutch structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

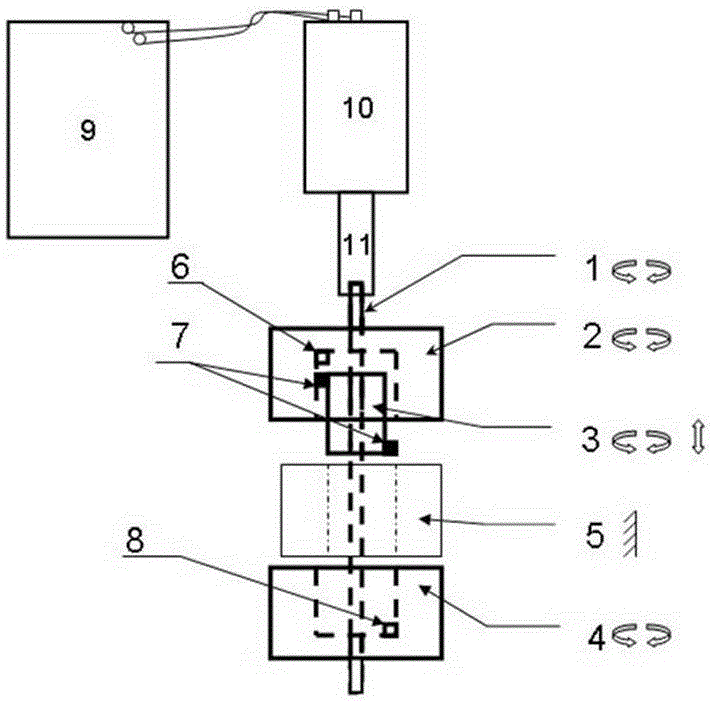

[0012] Combine below figure 1 Further detailed description of the embodiments of the patent of the present invention.

[0013] combine figure 1 , an electronically controlled two-way three-state clutch of the patent of the present invention is mainly composed of an electronically controlled power input shaft [1], a positive rotation power output body [2], a shaft sleeve with external threads [3], and a transition body [5] Composed of the reverse power output body [4], the shaft sleeve [3] with external thread is first set on the electric control power input shaft [1], and then the forward rotation power output body [2], transition body [5] , reverse power output body [4] suits above them successively. Among them, the inner hole of the shaft sleeve [3] with external thread is set as a square hole, which cooperates with the square cylindrical surface of the electric control power input shaft [1], and the two can only slide freely along the rotation axis and cannot rotate relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com