Shock absorption structure of pull rod suspension device

A vibration-damping structure and hanging technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problem of not being able to solve vibration reduction and service life at the same time, achieve excellent vibration reduction effect, simplify the tasks of regular inspection and maintenance, and reduce vibration effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

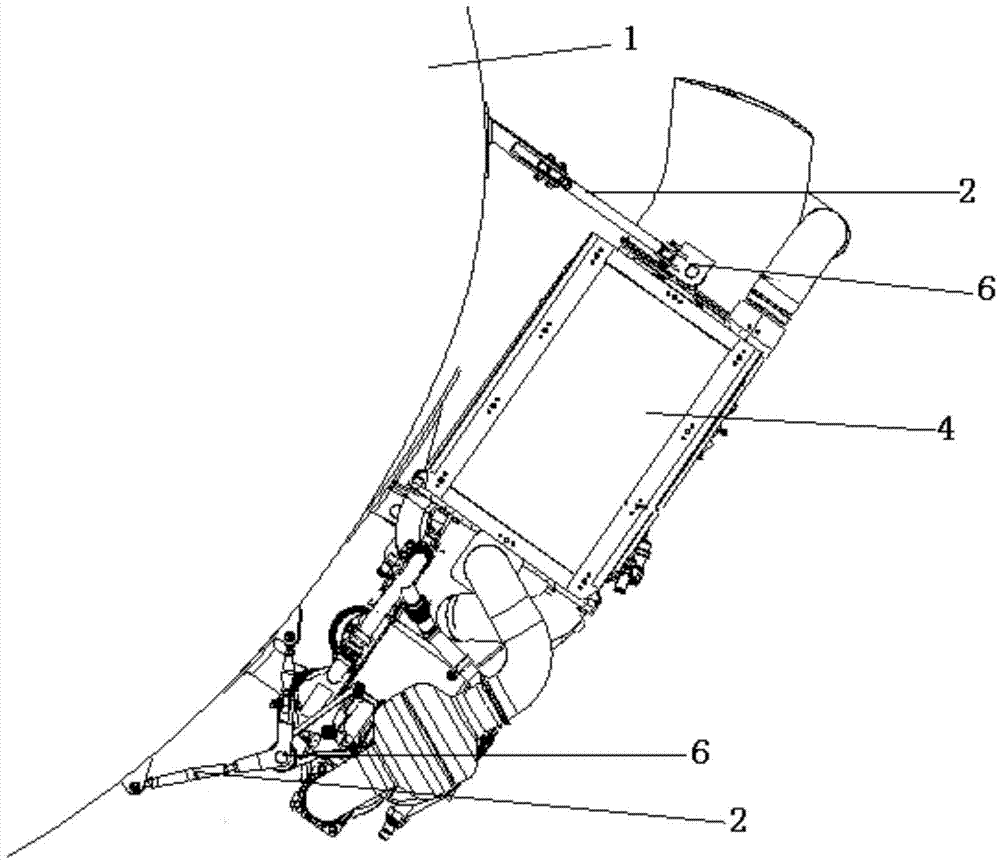

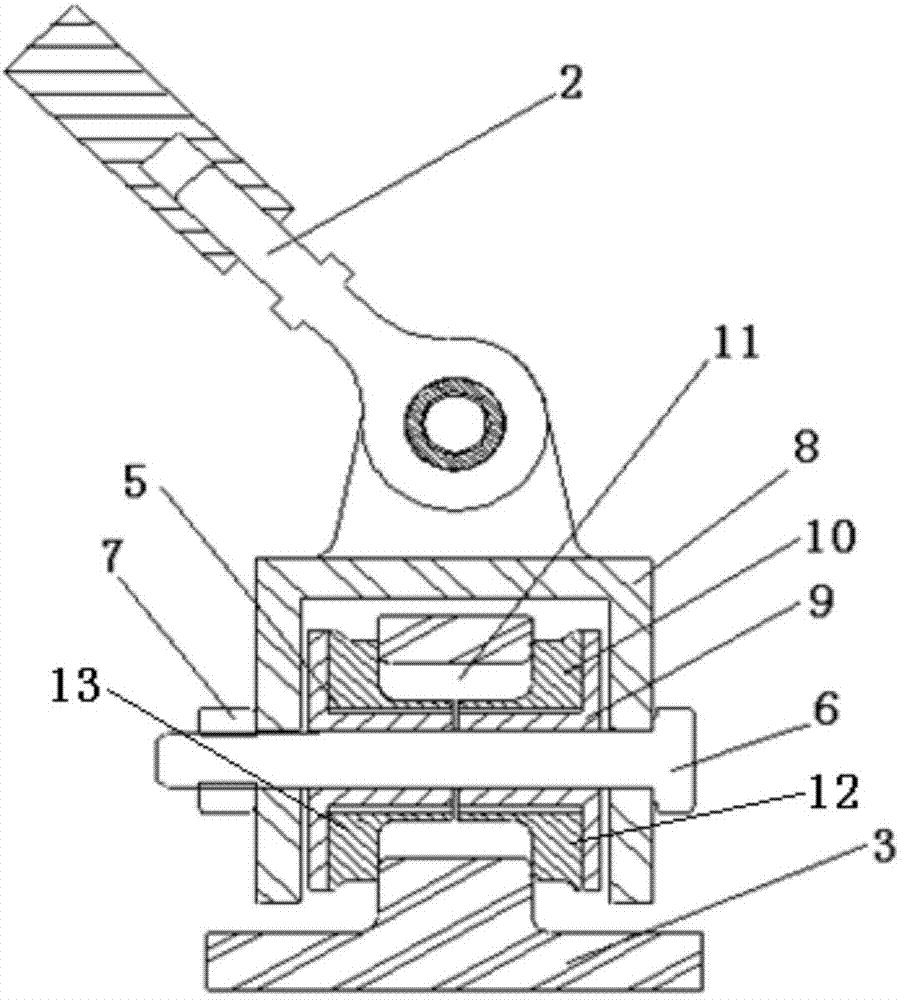

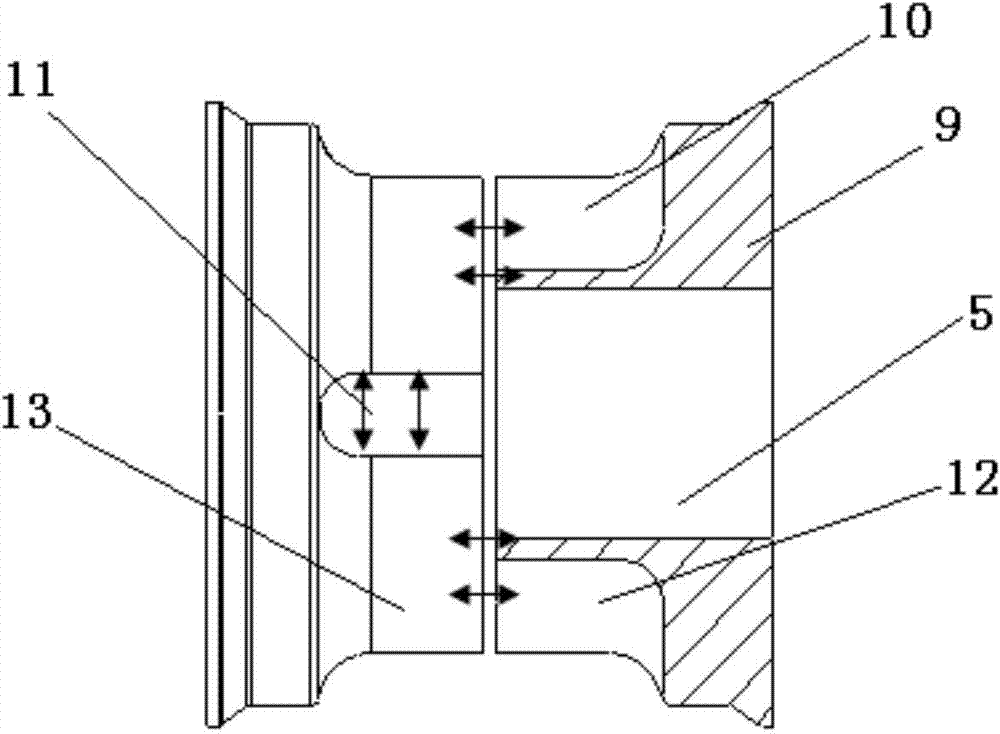

[0013] As shown in the figure, in implementation, the airborne equipment 4 needs to be hung on the aircraft body 1 through the pull rod 2, and the airborne equipment 4 is provided with a connecting seat 3 for hanging and a connecting hole on the connecting seat. One end connected to the body 1 is ready for installation, and the other end of the pull rod 2 is provided with a connecting fork 8 for hanging the airborne equipment, and the fork is provided with a connecting hole corresponding to the connecting hole of the equipment connecting seat. During installation, the airborne equipment 4 is placed in a suitable position through the ground support equipment. The shock-absorbing bushing 5 is embedded in the connection hole of the connecting seat 3 of the hanging equipment, and the connecting bolt 6 passes through the central hole of the shock-absorbing bushing 5 and the connecting hole on the connecting fork lug to fix the airborne equipment on the end of the tie rod 2 , the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com