Outer spline gear and spline gear transmission device

A technology of external splines and involute external splines, which is applied in the directions of hoisting devices, portable lifting devices, belts/chains/gears, etc., and can solve problems such as large axial space and difficult transmission system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

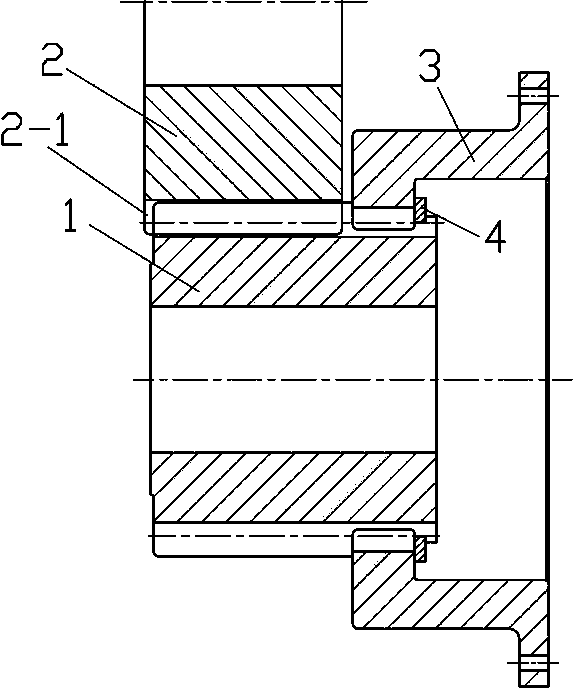

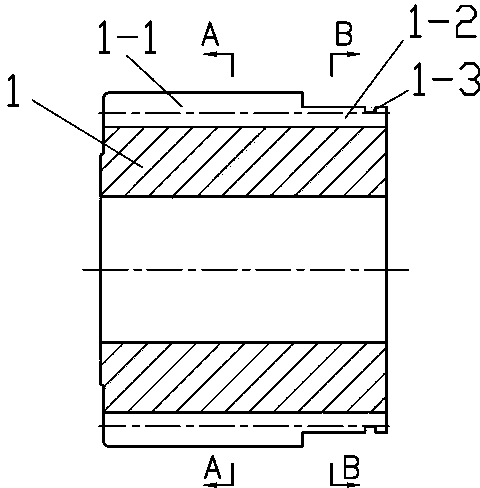

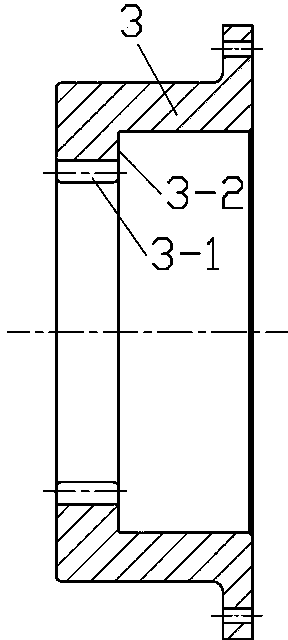

[0018] Such as figure 2 , 4 , 5, the external spline gear of the present invention, the teeth of the external spline gear 1 are straight teeth, and each tooth includes an involute gear tooth 1-1 segment and an involute external spline 1-2 sections of teeth, the 1-1 section of the involute gear teeth and the 1-2 section of the involute external spline teeth are integrated, and the 1-2 sections of the involute external spline teeth There is a slot 1-3 away from the involute gear teeth 1-1, and the number of teeth 1-2 of the involute external spline is z 2 , modulus m 2 , pressure angle α 2 , Variation coefficient X 2 and dedendum height factor h * f2 Teeth number z with involute gear teeth 1-1 1 , modulus m 1 , pressure angle α 1 , Variation coefficient X 1 and dedendum height factor h * f1 Same, the tooth height coefficient h of the involute external spline teeth 1-2 * a2 It is less than the tooth height coefficient h of the involute gear teeth 1-1 * a1 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com