A sealing ring, a split sealing structure and a processing technology for the sealing ring

A technology of processing technology and sealing structure, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of complex processing procedures and poor sealing effect of sealing rings, shorten the processing time, increase the number of changes, and improve the sealing effect. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

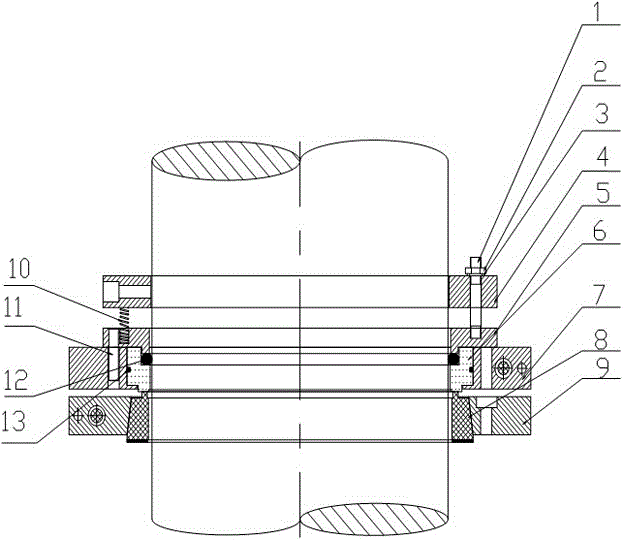

[0031] like figure 1 As shown, a split sealing structure of the present invention includes a static ring seat 9, a static sealing ring 8 is installed in the static ring seat 9, and the static sealing ring and the static ring seat 9 are fixedly connected by taper fit. , install this part on the equipment, and also include the dynamic ring seat 7, the dynamic ring seat 7 is located above the static ring seat 9, the dynamic sealing ring 6 is installed in the static ring seat, and the outer surface of the dynamic sealing ring 6 is provided with a buffer groove , a buffer strip 13 is installed in the buffer tank for sealing between the dynamic seal ring 6 and the dynamic ring seat 7, a push ring 5 is fixedly connected to the dynamic ring seat 7 by bolts, and a push ring 5 is arranged above the push ring 5 Spring seat 4, a plurality of springs 10 are installed between the spring seat 4 and the push ring 5, and the adjusting screw rod 1 that regulates the spacing between the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com