Composite building wall module, modular building wall and preparation method and application

A composite material and building wall technology, applied in the field of new materials and temporary buildings, can solve the problems of poor fireproof performance, poor sound insulation effect and insufficient strength, and achieve the effects of increasing sound insulation effect, easy replacement and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

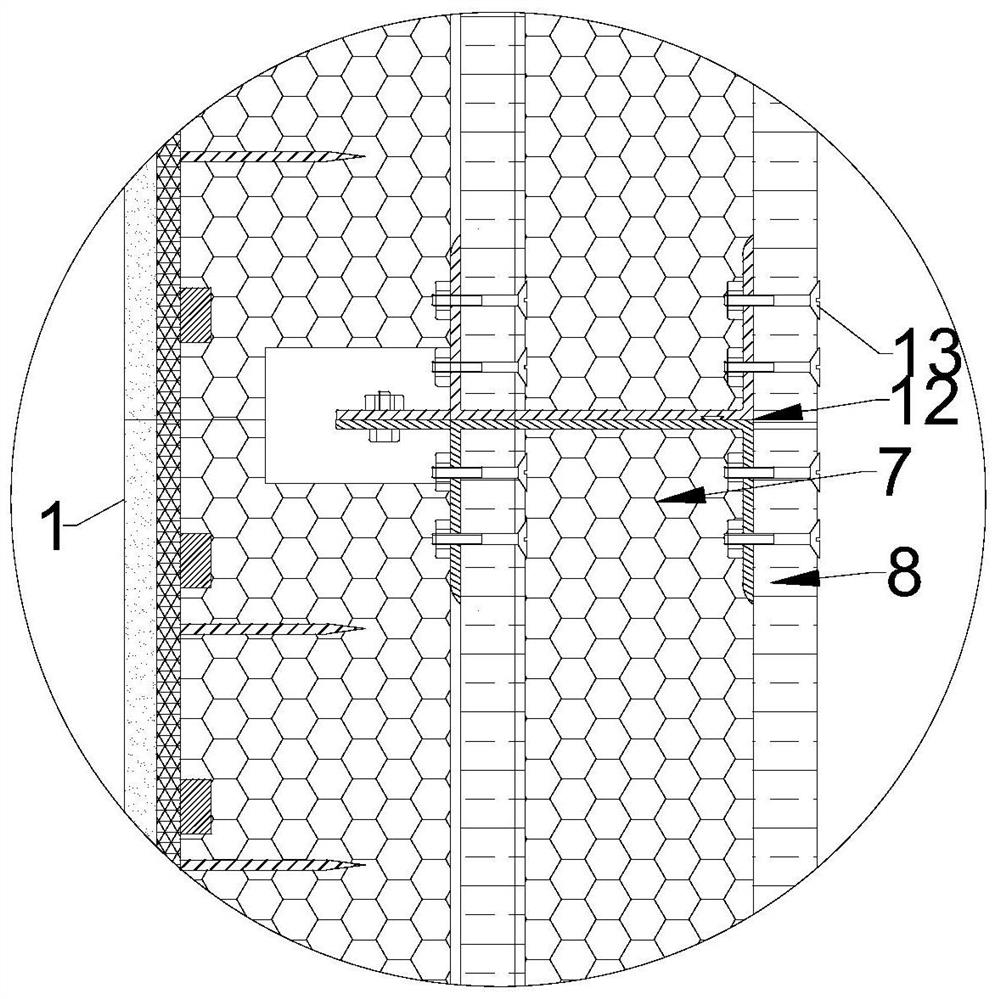

[0049] The third embodiment of the present invention provides a method for preparing a modular building wall, providing a plurality of the above-mentioned composite building wall modules, and connecting the bottom plates of the light steel connectors of every two composite building wall modules until the Assemble all composite building wall modules into one wall.

[0050] The fourth embodiment of the present invention provides an application of the above-mentioned composite material building wall module and / or modular building wall in the construction of temporary buildings.

[0051] In order to enable those skilled in the art to understand the technical solutions of the present invention more clearly, the technical solutions of the present invention will be described in detail below with reference to specific embodiments.

Embodiment 1

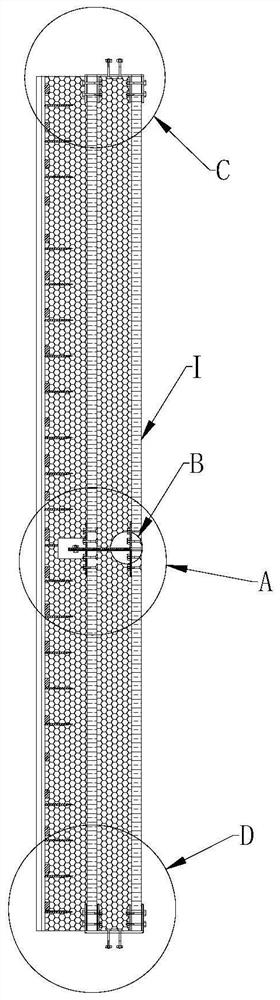

[0053] A modular building wall such as figure 1 As shown, it is assembled from a plurality of composite building wall modules I.

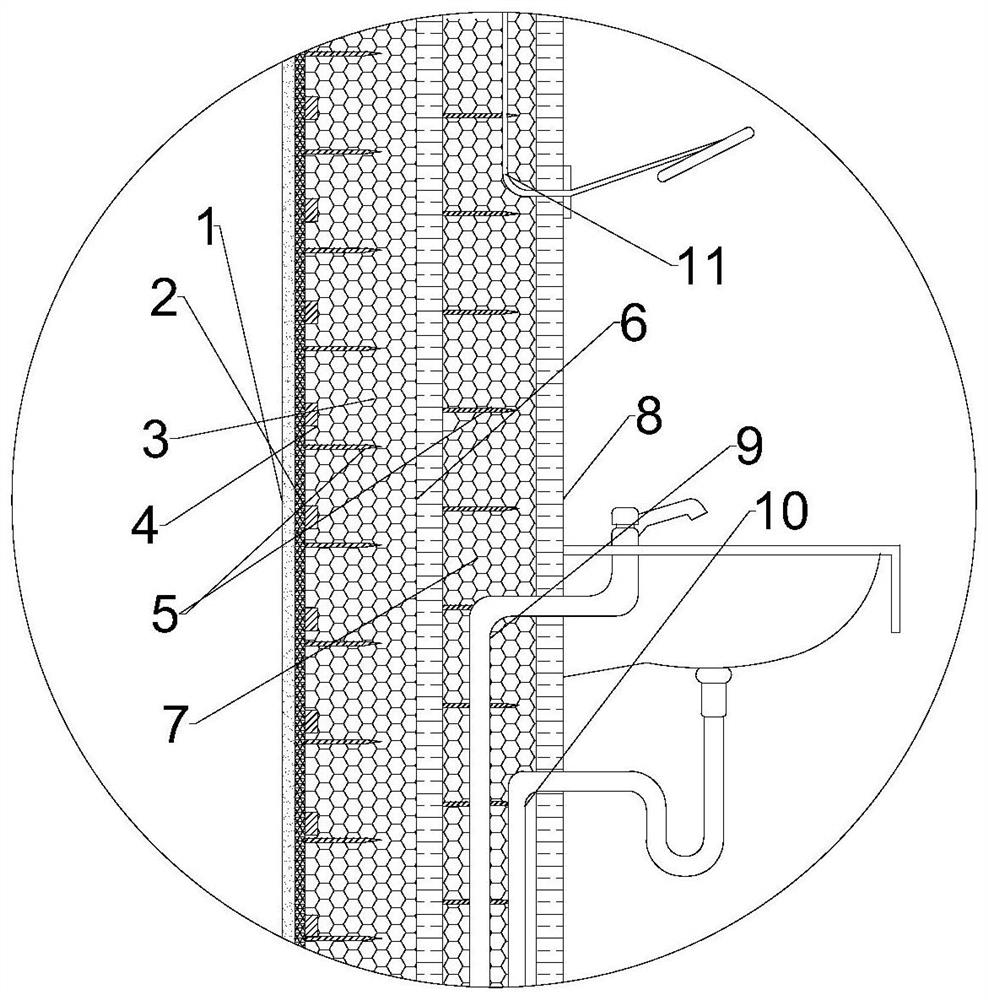

[0054] Composite building wall modules such as figure 2 As shown, the cement mortar surface layer 1, the bonding reinforcement layer 2, the first thermal insulation layer 3, the first glass fiber reinforced composite board 6, the second thermal insulation layer 7 and the second glass fiber reinforced composite board ( i.e. veneer panels) 8. The second insulation layer 7 is embedded with a functional pipe network, which includes a water supply pipe 9 , a drainage pipe 10 and an electric wire pipe 11 . Among them, the second glass fiber reinforced composite board 8 is attached with decorative panels on the surface according to requirements, and embedded with functional accessories such as lamps and sockets. The cement mortar surface layer 1 is made of cement mortar and quartz sand, which is waterproof and sunscreen, and is firm and durable. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com