Integrated valve

An integrated valve and valve body technology, applied in the field of integrated valves, can solve the problems of clean gas discharge, uncompact product structure, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

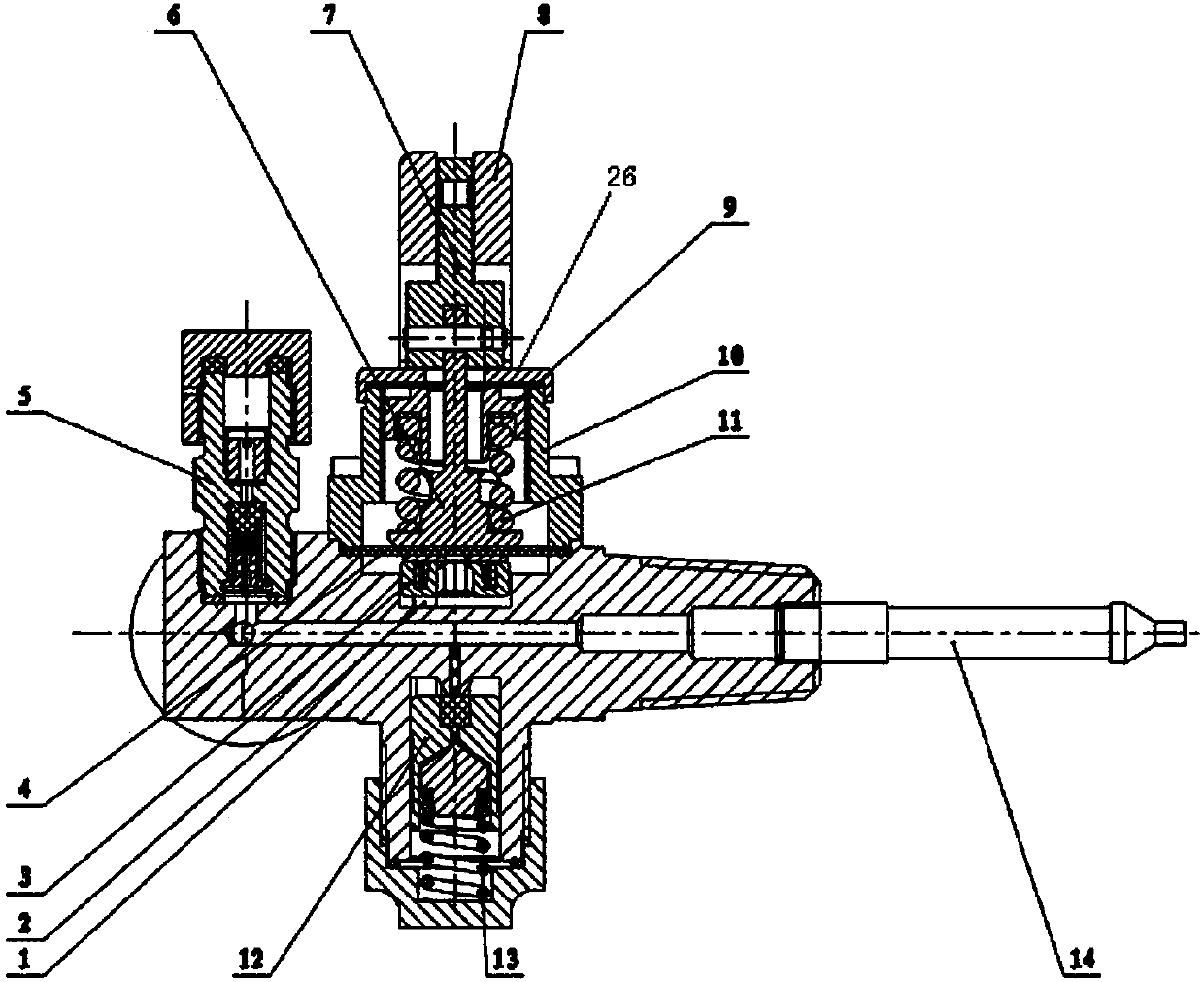

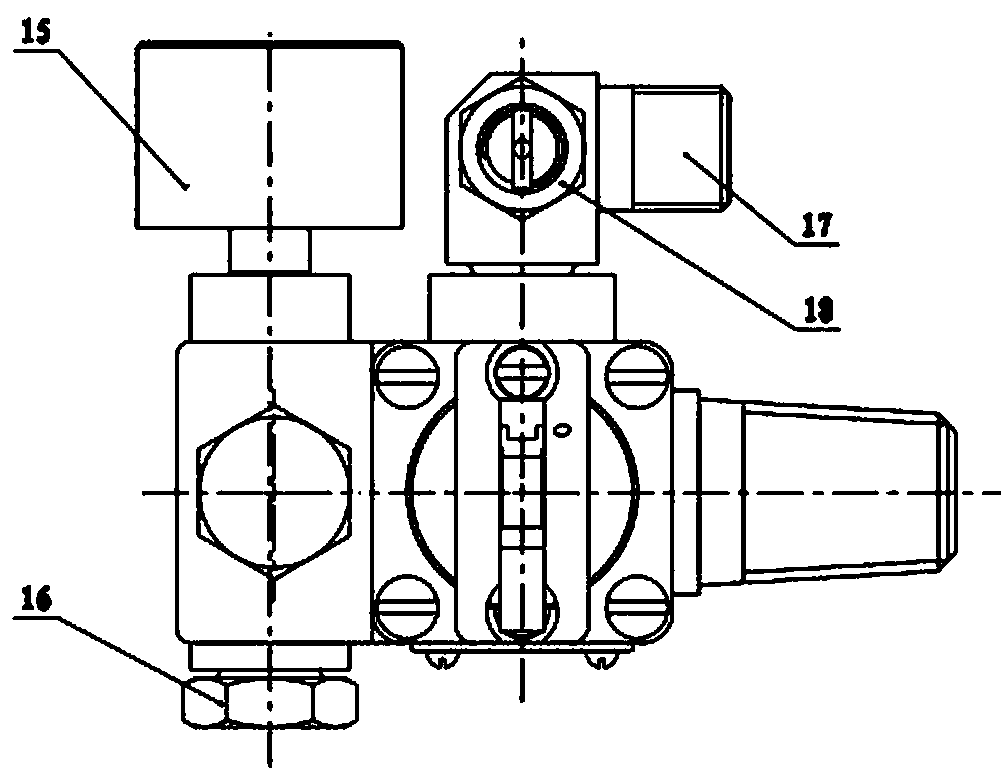

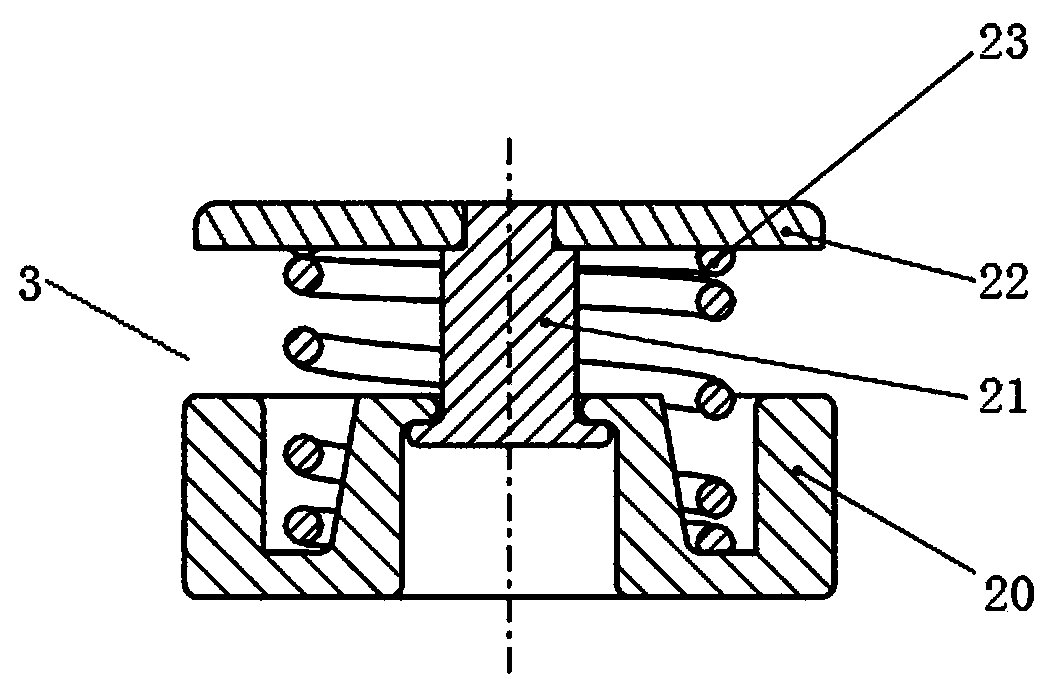

[0020] Examples of integrated valves are Figure 1~5 Shown: including the valve body 1, the valve body is provided with a gas cylinder interface and an air inlet channel and an air outlet channel 24 connected with the gas cylinder interface. Inflatable joint 5, pressure gauge 15 and blocking cap 16, inflating joint 5 has filter screen, can realize the filtration to gas impurity when inflating, and blocking cap 16 can realize the release of residual pressure in the bottle or as a spare interface. The inlet end of the air outlet channel and the outlet end of the inflatable channel share a section of gas path. The inlet end of the air outlet channel is provided with a filter 14, and the outlet end of the air outlet channel is provided with an air outlet joint 17 and a safety valve 18. The safety valve can ensure that the The pressure is not higher than the set value, such as 0.9Mpa, to ensure the safety of the back-end devices. A spool 12 is installed in the valve body to guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com