Fixing structure of light source panel of LED (light-emitting diode) lamp

A technology of LED light source and fixed structure, applied in the field of lighting, can solve the problems of complex process, difficult to realize automatic production, unable to guarantee production efficiency, etc., and achieve the effect of simple structure and high assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

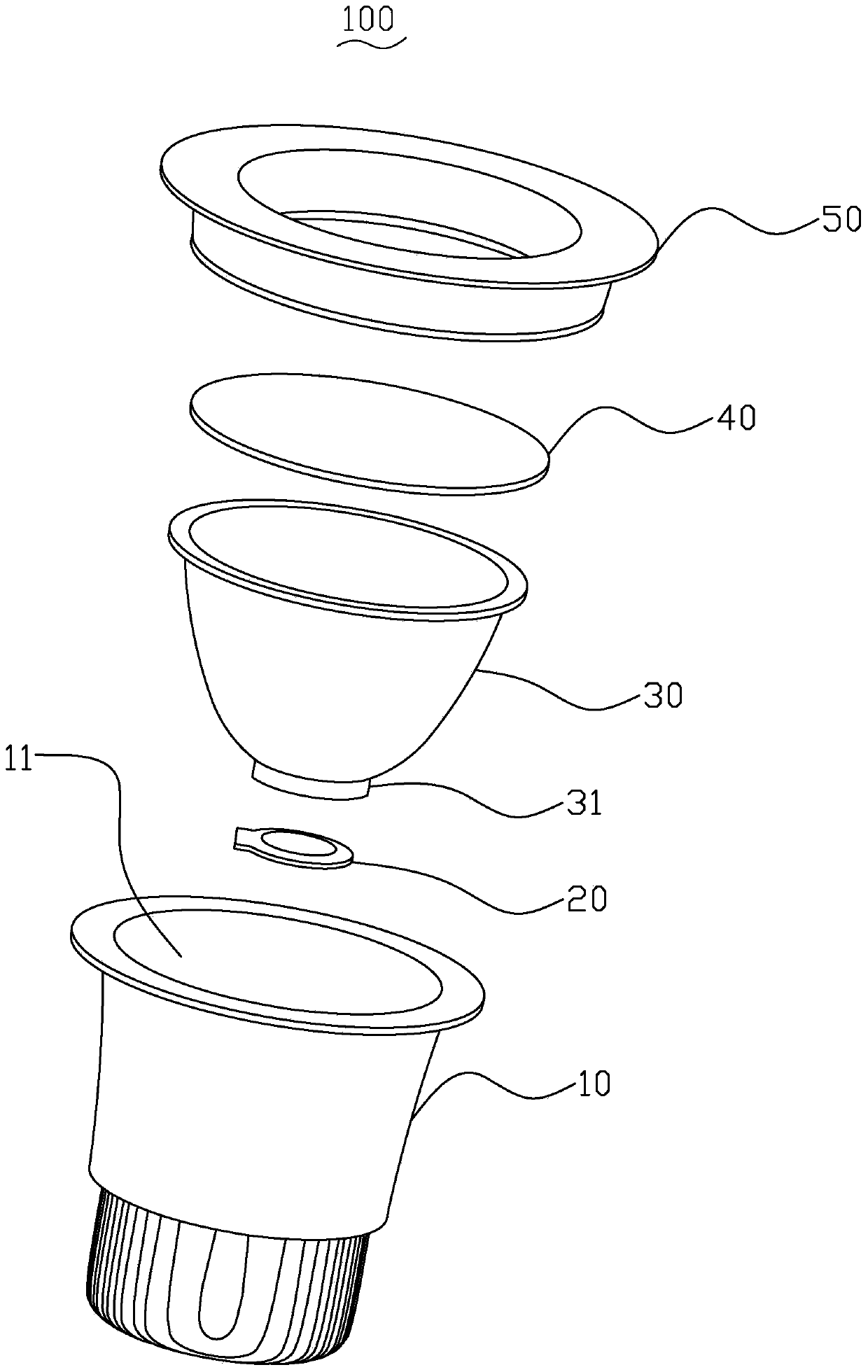

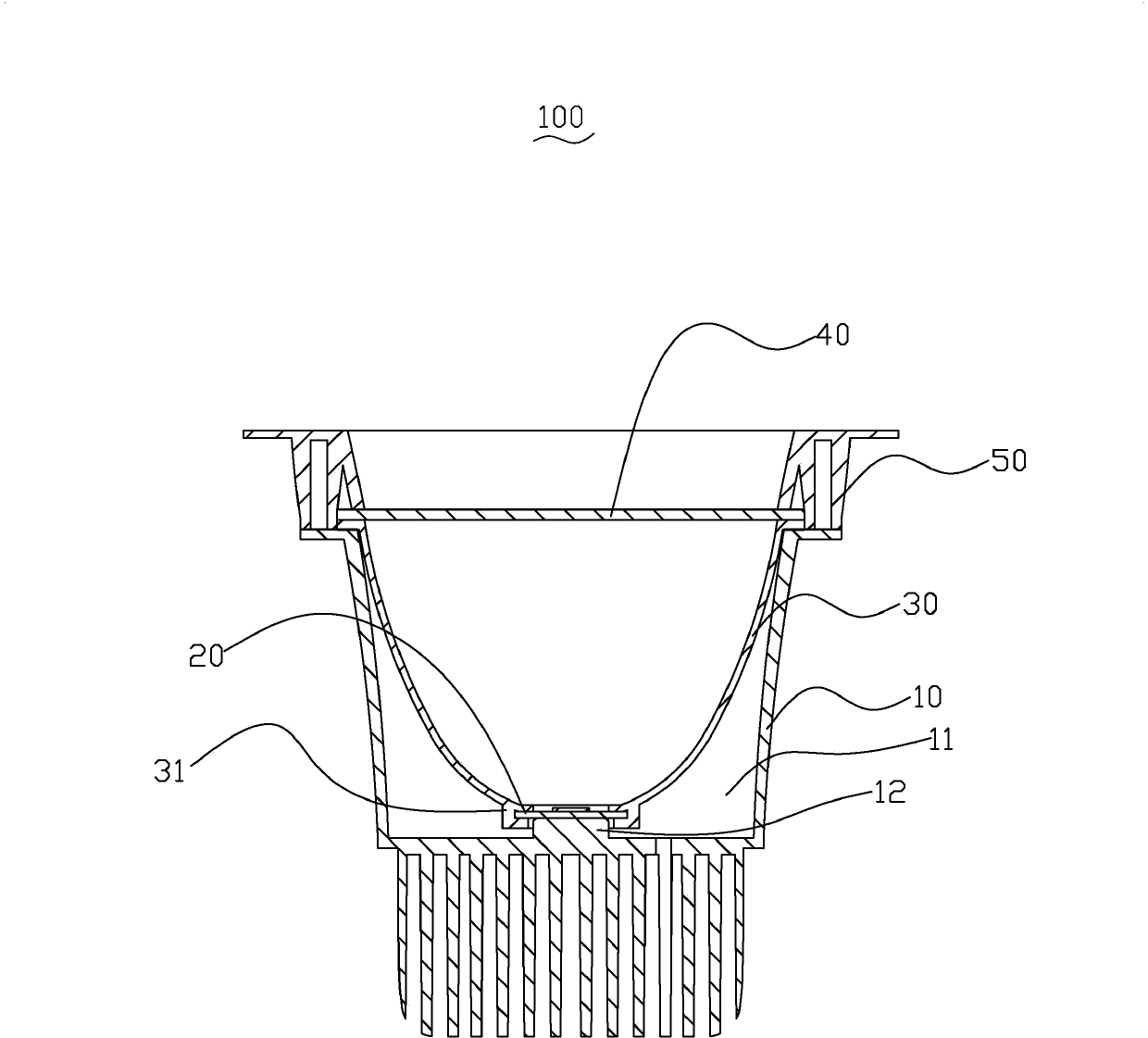

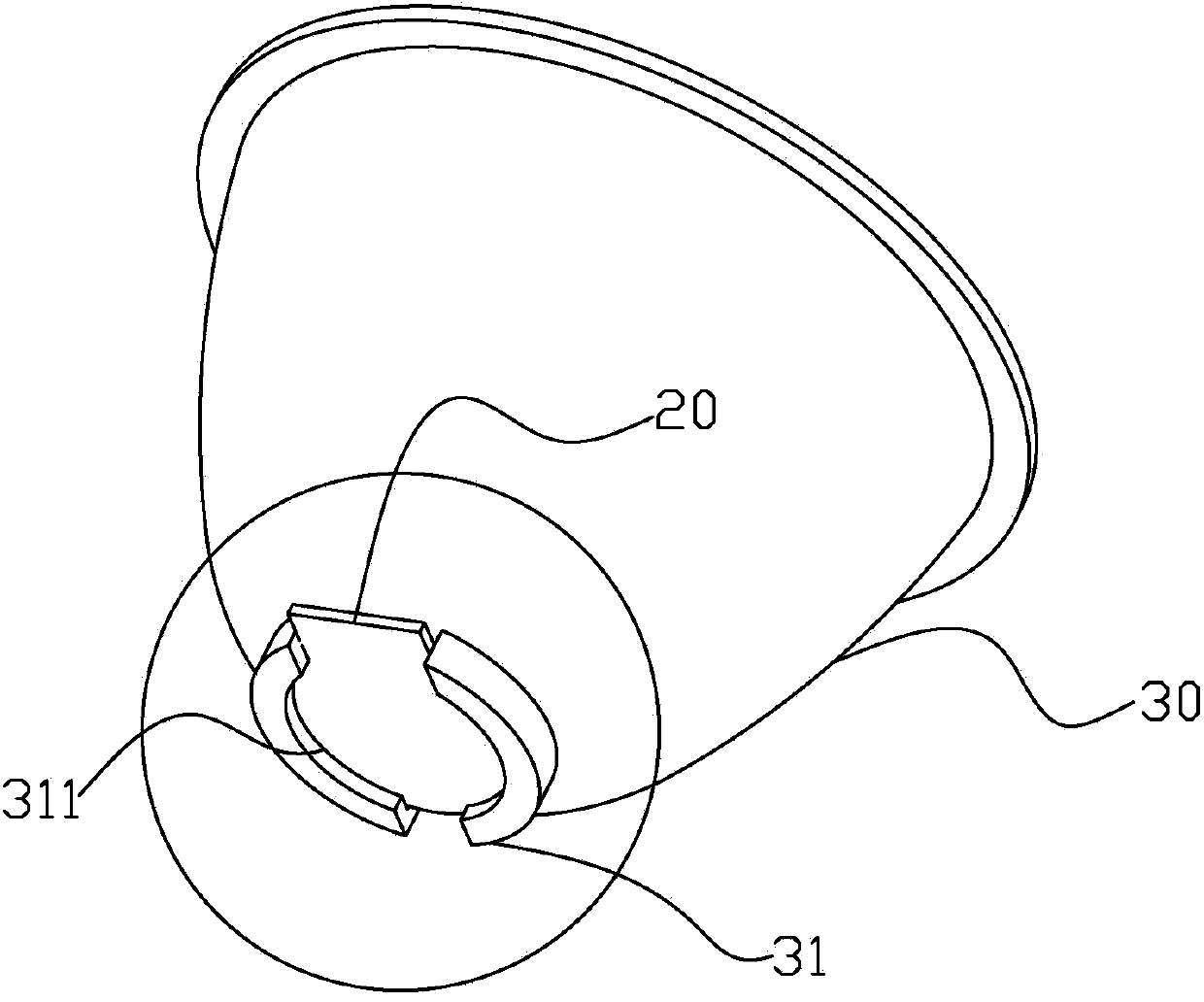

[0017] figure 1 It is a three-dimensional exploded view of the LED light source board fixing structure 100 of the first embodiment of the present invention applied to the LED lamp. The LED lamp includes a radiator 10, an LED light source board 20, a lamp cup 30, a lens 40 and a lamp body 50. The lamp body 50 is fixed on the top of the heat sink 10, the top of the lamp cup 30 is fixed on the lamp body 50, the LED light source board 20 is arranged on the heat sink 10, the top of the lamp cup 30 is provided with a lens 40, The lens 40 is set corresponding to the LED light source board 20 . The bottom of the lamp cup 30 is provided with a pressing member 31 corresponding to the LED light source board 20 , and the lamp cup 30 elastically presses the LED light source board 20 toward the heat sink 10 through the pressing member 31 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com