Fully automatic constant-temperature and constant-pressure water supply system

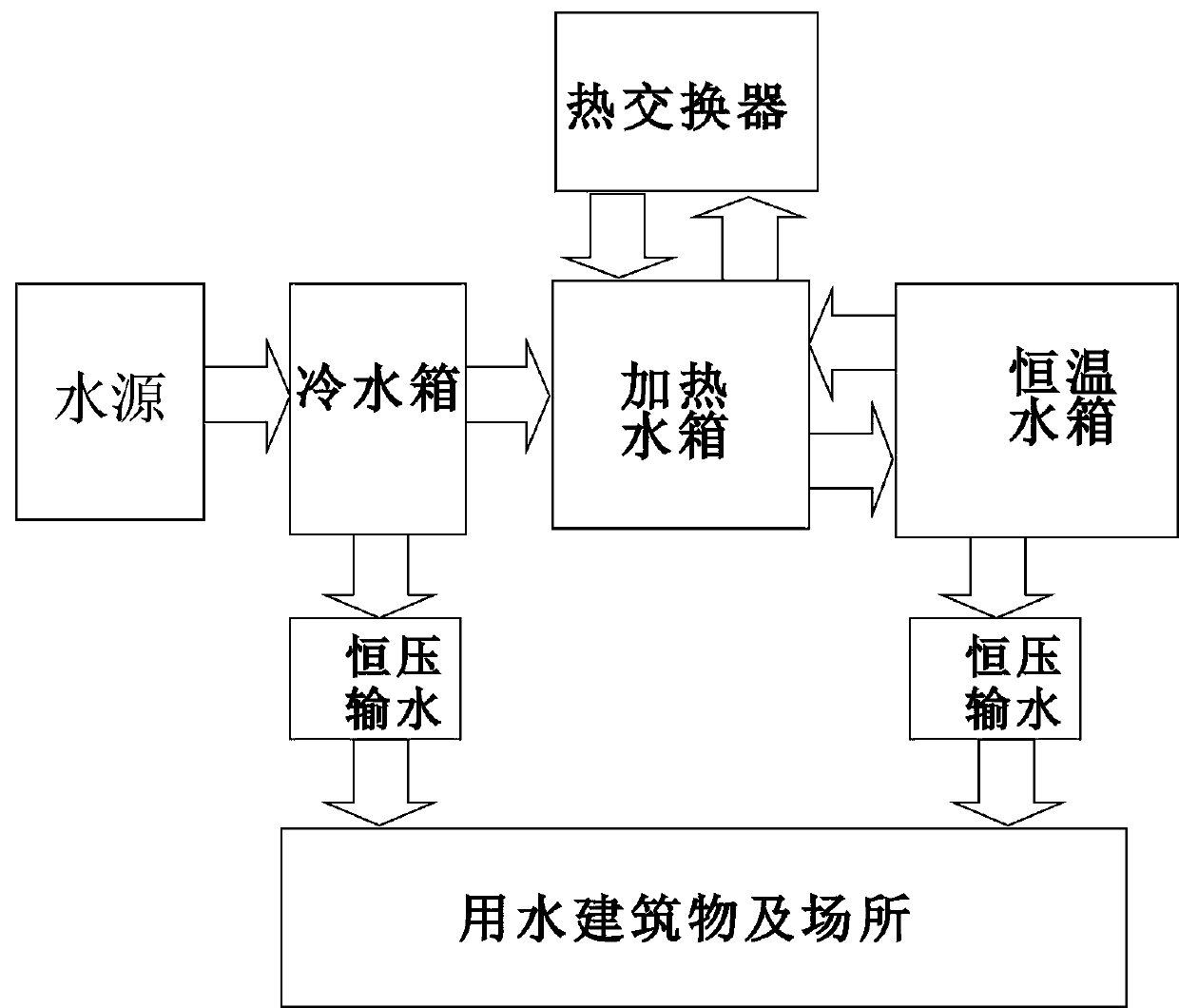

A constant temperature and constant pressure, water supply system technology, applied in heating systems, water supply pipeline systems, residential hot water supply systems, etc., can solve problems such as guest injuries, large pressure fluctuations, complaints, etc., to achieve universal, stable and reliable The effect of constant temperature and pressure water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

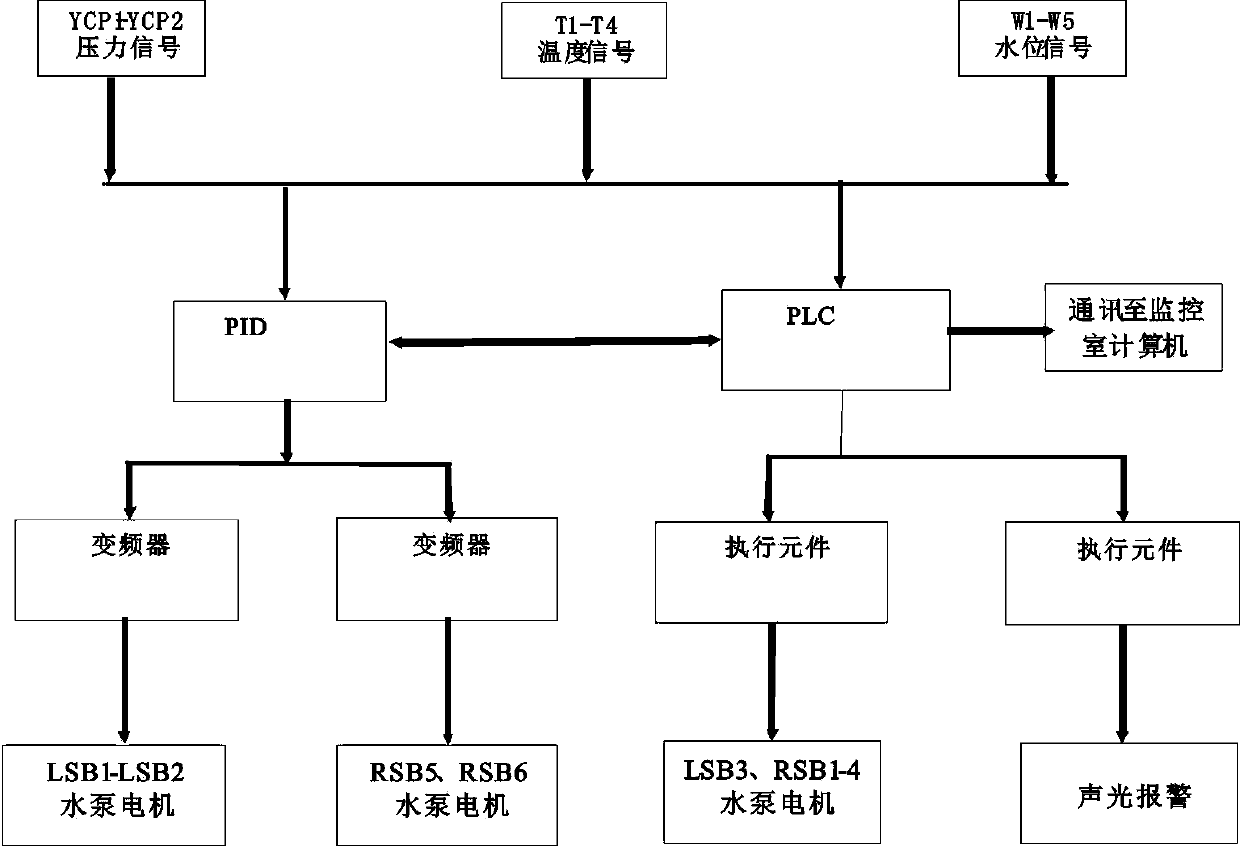

Method used

Image

Examples

Embodiment

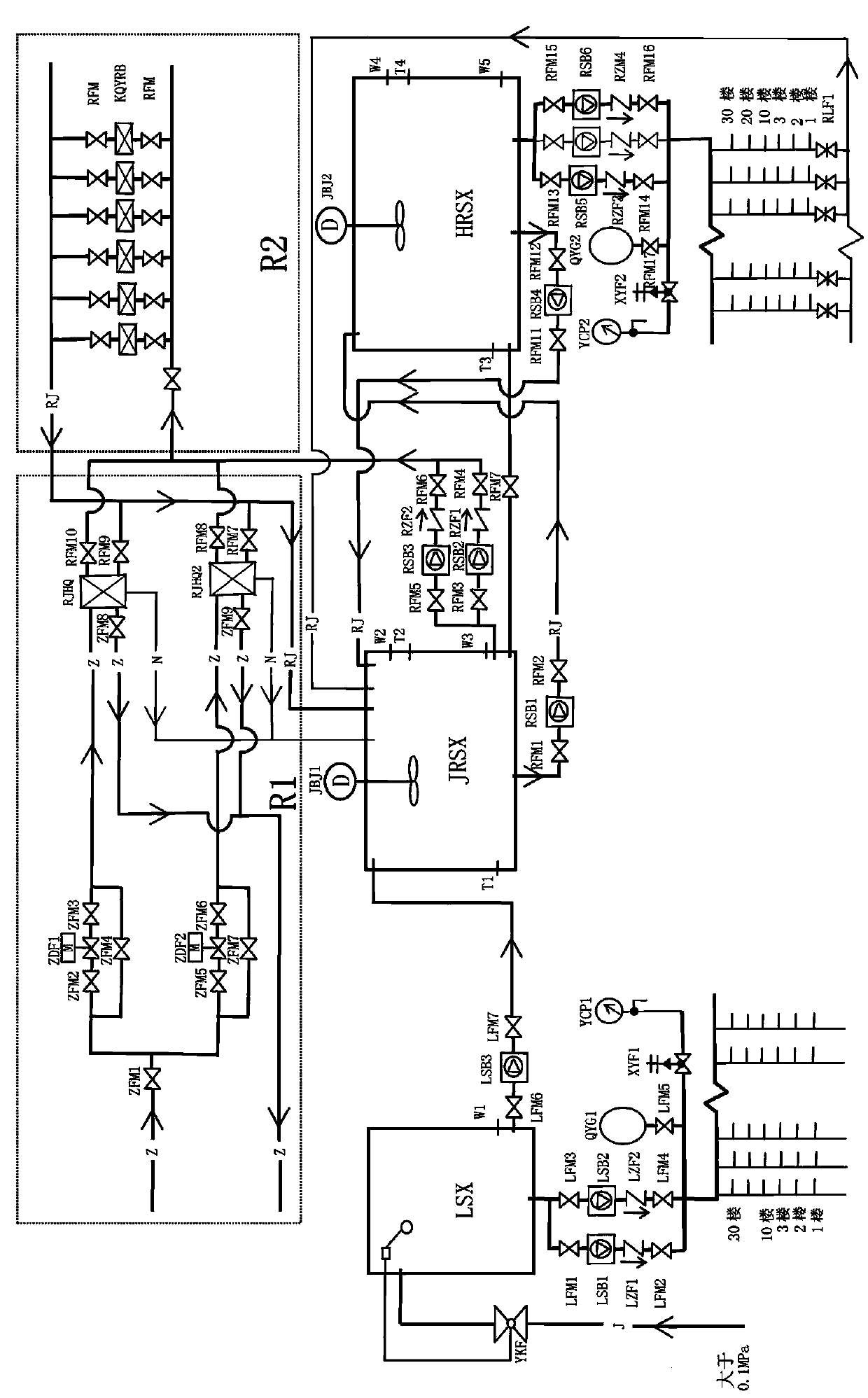

[0033] Such as image 3 As shown, the components include: cold water tank LSX, heating water tank JRSX, constant temperature water tank HRSX, remote control float valve YKF, cold water butterfly valve LFM1-7, first cold water check valve LZF1, second cold water check valve LZF2, first cold water pump LSB1 , the second cold water pump LSB2, the third cold water pump LSB3, the first remote pressure gauge YCP1, the second remote pressure gauge YCP2, the first mixer JBJ1, the second mixer JBJ2, hot water butterfly valve RFM1-17, hot water pump RSB1- 6. Hot water check valve RZF1-4, return water regulating valve RLF1-N, steam valve ZFM1-9, steam solenoid valve ZDF1-2, first heat exchanger RJHQ1, second heat exchanger RJHQ2, digital thermometer T1 -4, liquid level switch W1-5, steam pipe Z, hot water pipe RJ, condensate pipe N, domestic water pipe J, first diaphragm pressure tank QYG1, second diaphragm pressure tank QYG2, pressure relief valve XYF1-2, hot water Butterfly valve RFM1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com