A Mechanical Fault Diagnosis Method Based on Planar Clustering and Frequency-Domain Compressed Sensing Reconstruction

A frequency-domain compression, mechanical fault technology, applied in the field of mechanical equipment condition monitoring and fault diagnosis, can solve problems such as many interference sources, strong background noise in industrial sites, and unclear number of fault sources, and achieve the effect of weakening the impact of fault identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

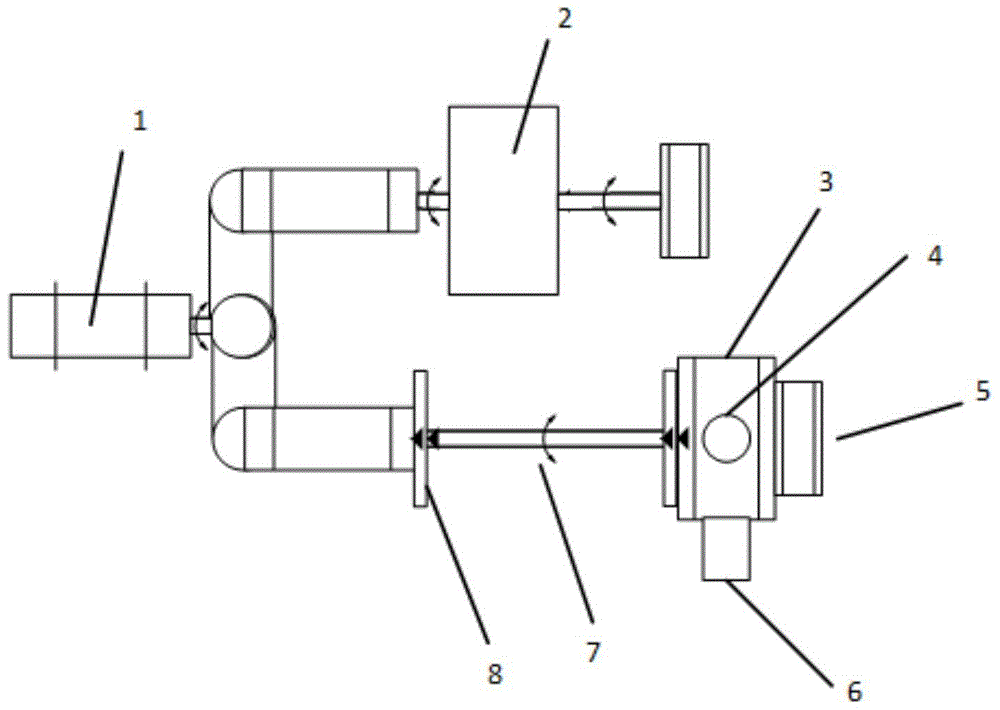

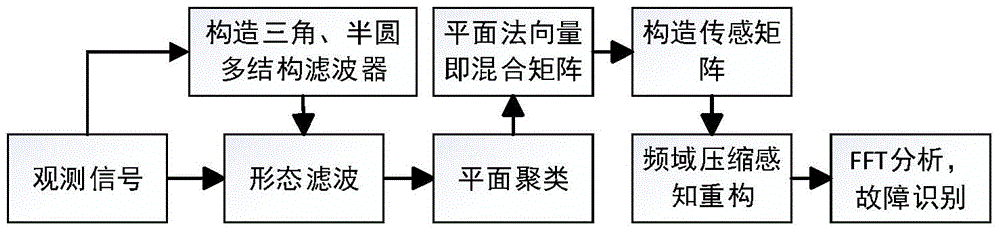

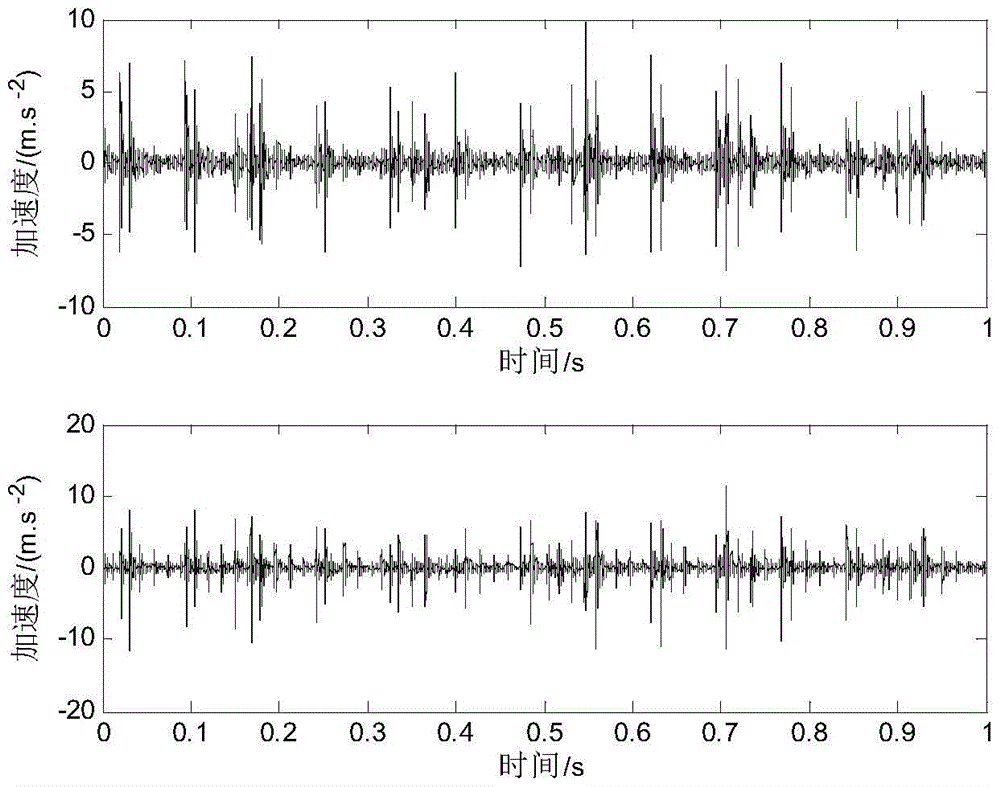

[0045] Embodiment 1: as Figure 1-6 As shown, a mechanical fault diagnosis method based on plane clustering and frequency-domain compressive sensing reconstruction, firstly, the acceleration sensor is installed on the surface of the mechanical equipment, and the observation signal of mechanical vibration is picked up by the acceleration sensor; the observation signal is averaged Then calculate the length and height set of the triangular and semicircular structural elements after the mean value processing; then construct the triangular structural element set and the semicircular structural element set, and then construct an improved multi-structure generalized closed-open combination morphological filter, The improved multi-structure generalized closed-open combined morphological filter is used to filter the averaged processing results of the observed signals to obtain the filtered signal; the filtered signal is estimated by the plane clustering algorithm to estimate the mixing ...

Embodiment 2

[0046] Embodiment 2: as Figure 1-6 As shown, a mechanical fault diagnosis method based on plane clustering and frequency-domain compressive sensing reconstruction, firstly, the acceleration sensor is installed on the surface of the mechanical equipment, and the observation signal of mechanical vibration is picked up by the acceleration sensor; the observation signal is averaged Then calculate the length and height set of the triangular and semicircular structural elements after the mean value processing; then construct the triangular structural element set and the semicircular structural element set, and then construct an improved multi-structure generalized closed-open combination morphological filter, The improved multi-structure generalized closed-open combined morphological filter is used to filter the averaged processing results of the observed signals to obtain the filtered signal; the filtered signal is estimated by the plane clustering algorithm to estimate the mixing ...

Embodiment 3

[0063] Embodiment 3: as Figure 1-6 As shown, a mechanical fault diagnosis method based on plane clustering and frequency-domain compressive sensing reconstruction, firstly, the acceleration sensor is installed on the surface of the mechanical equipment, and the observation signal of mechanical vibration is picked up by the acceleration sensor; the observation signal is averaged Then calculate the length and height set of the triangular and semicircular structural elements after the mean value processing; then construct the triangular structural element set and the semicircular structural element set, and then construct an improved multi-structure generalized closed-open combination morphological filter, The improved multi-structure generalized closed-open combined morphological filter is used to filter the averaged processing results of the observed signals to obtain the filtered signal; the filtered signal is estimated by the plane clustering algorithm to estimate the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com