Trip device and spring operating mechanism using the trip device

A technology of tripping device and operating mechanism, which is applied in the direction of contact operating mechanism, power device inside the switch, contact vibration/shock damping, etc., and can solve the problem of damage to the moving contact, failure of tripping, and affecting the initial speed of opening and other problems, to achieve the effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

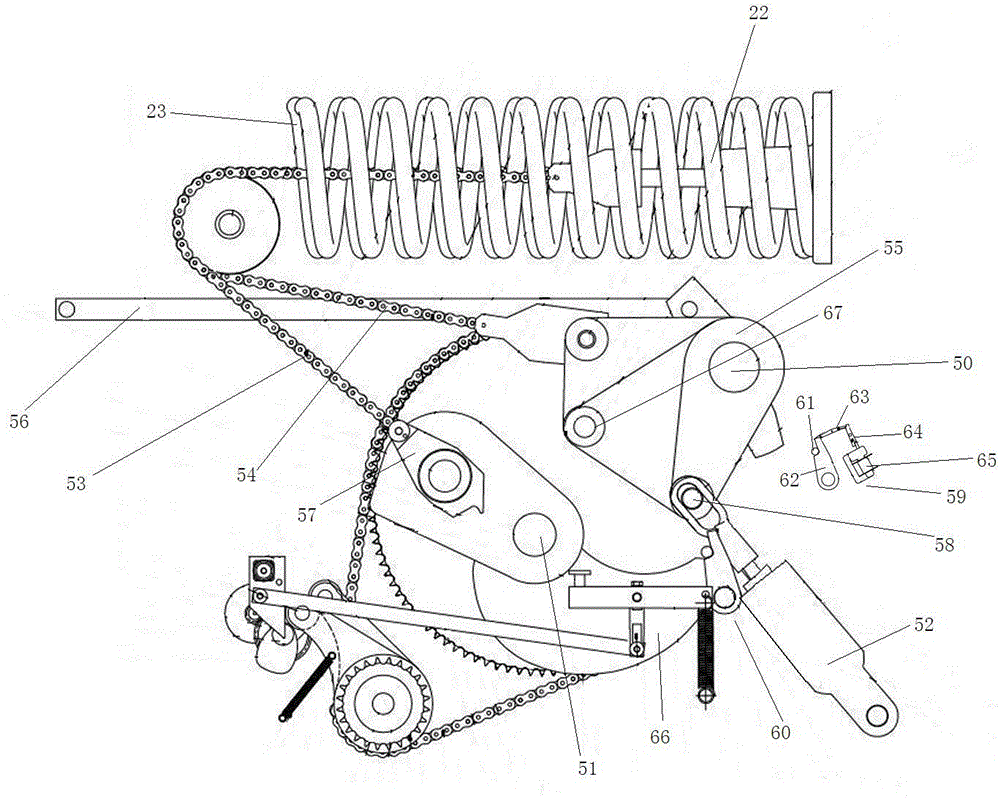

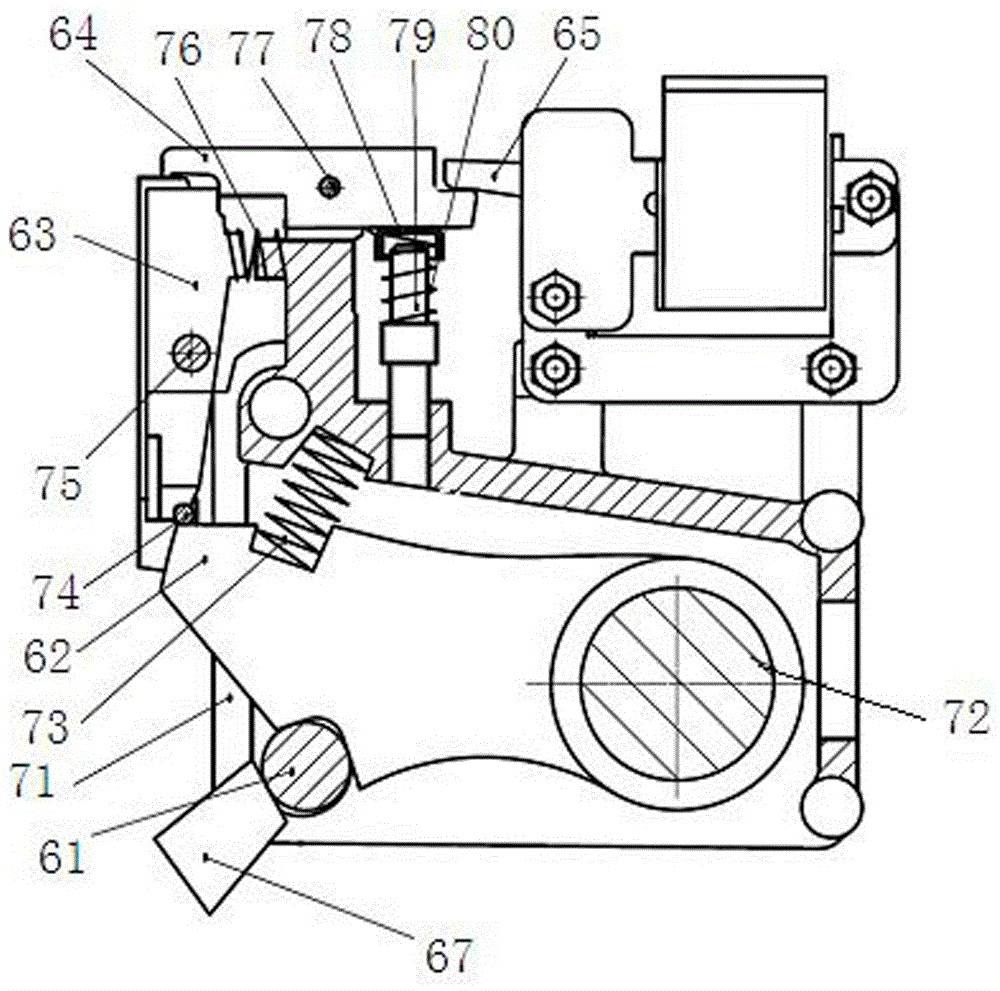

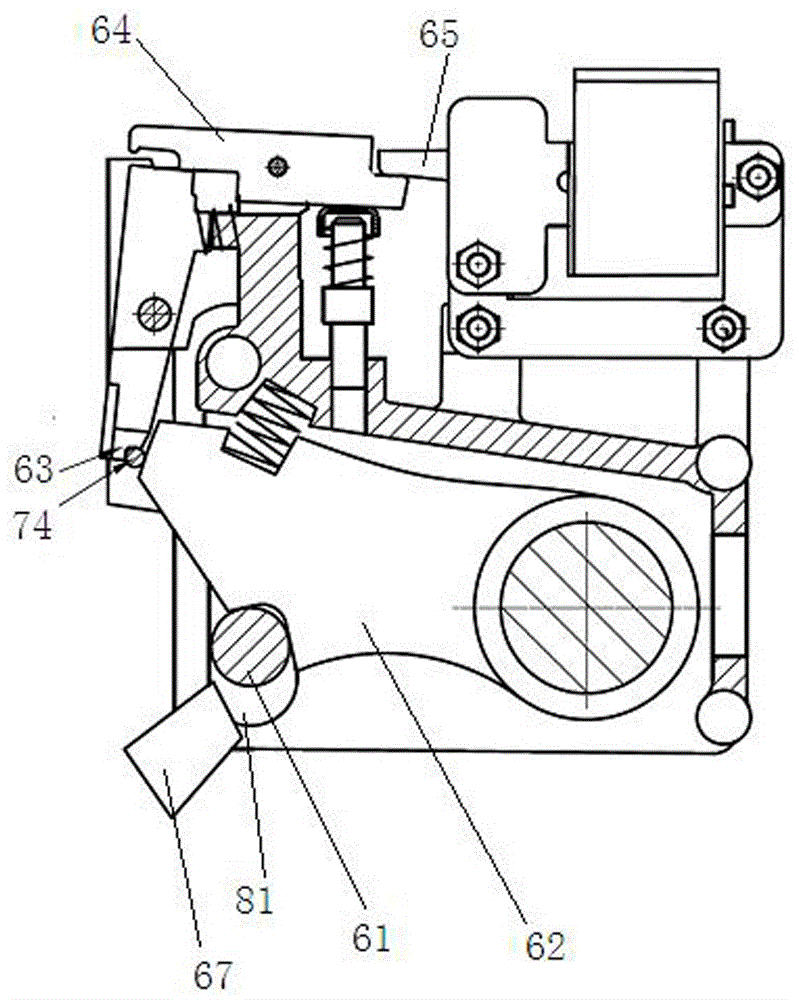

[0033] Examples of spring-operated mechanisms are Figure 1~14 Shown: including a frame, the frame is provided with an energy storage spring buffer 52 and an output shaft 50 and an energy storage shaft 51 whose axis extends in the left and right directions. The energy storage spring is divided into an opening spring 23, a closing spring 22, an energy storage The shaft is provided with the energy storage shaft cam and the energy storage detent 57 connected with the closing spring by the closing spring chain 53, and the energy storage shaft sprocket is also arranged on the energy storage shaft, and the closing and release mechanism is arranged on the energy storage shaft sprocket. Buckle fittings, a closing and tripping device 60 is arranged next to the energy storage shaft, and the spring operating mechanism also includes a motor that is connected to the sprocket of the energy storage shaft through a transmission mechanism. The switch arm 55, the buffer lever is an integrated l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com