Overall drying and compressing die for multiple hydro-generator stator coils

A stator coil, integrated technology, applied in the field of multi-piece integral baking and pressing molds for hydroelectric stator coils, can solve the problems of large dispersion of coil geometric dimensions, unusable molds, and difficult control of consistency, and achieve saving in the oven. Regular space, geometric shape and size, and good coil consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

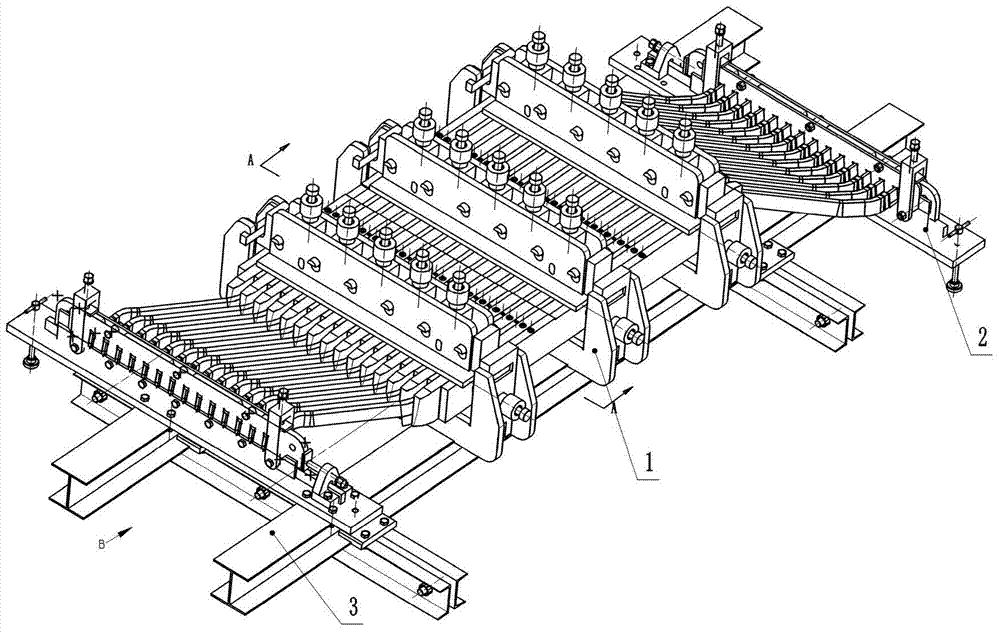

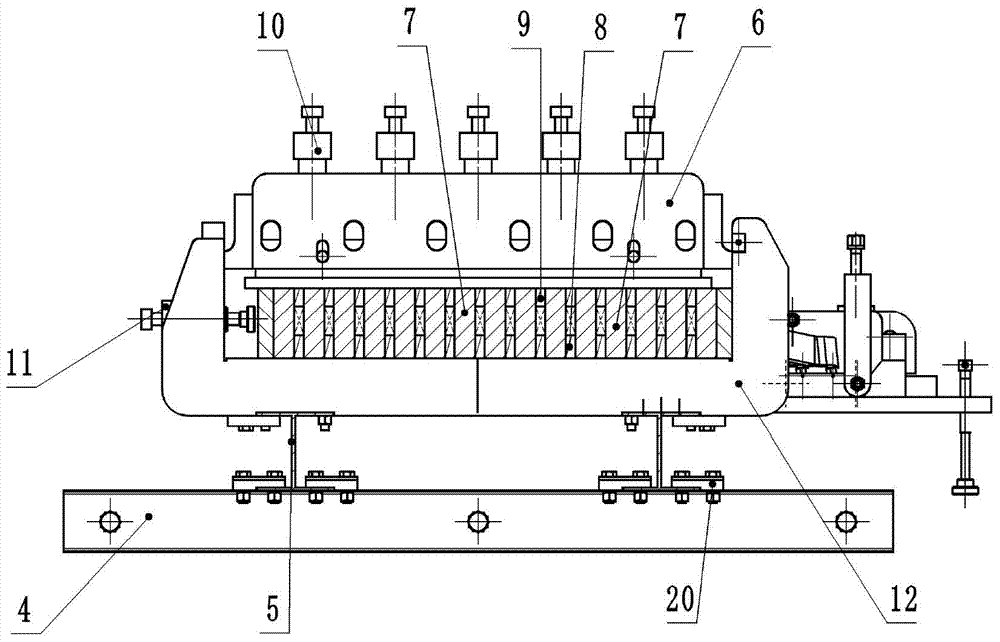

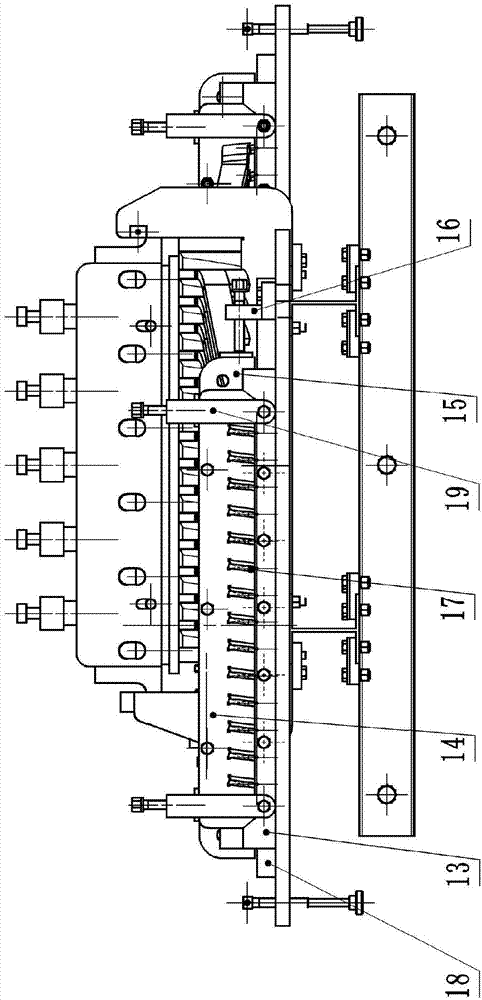

[0017] Such as figure 1 As shown in Fig. 1, there are multiple integral baking molds for hydroelectric stator coils. It consists of three parts: linear clamping body 1, end clamping body 2, and base 3. Wherein, the longitudinal support 5 is joined on the transverse support 4 with a pressure plate 20 and bolts, and the joint position can be adjusted according to the length of the stator coil to form the base 3, which is a common part. Linear clamping body parts such as figure 2 , consisting of a straight-line upper pressing beam 6, a straight-line spacer plate 7, a straight-line bottom pad iron 8, a straight-line upper weight iron 9, a pressurizing device 10, a straight-line C-shaped clip body 12, an end support plate 13, an end external tooth plate 14, The inner tooth plate 15 at the end, the side pressing and tightening device 16 at the end, the lifting block 17, the supporting plate 18 at the end and so on. According to the linear length of the coil, calculate and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com