a vacuum fryer

A vacuum fryer and tank technology, applied in the direction of oil/fat baking, oven door/flap gate, etc., can solve the problems of inaccurate installation position, dripping on the workbench, waste, etc., to achieve convenient operation, Precisely placed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

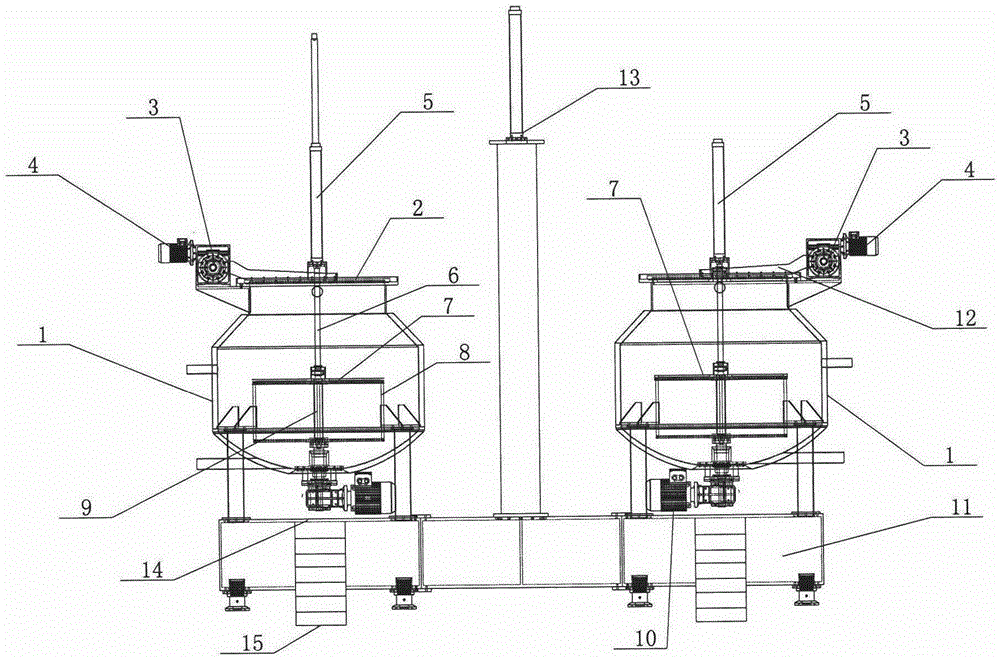

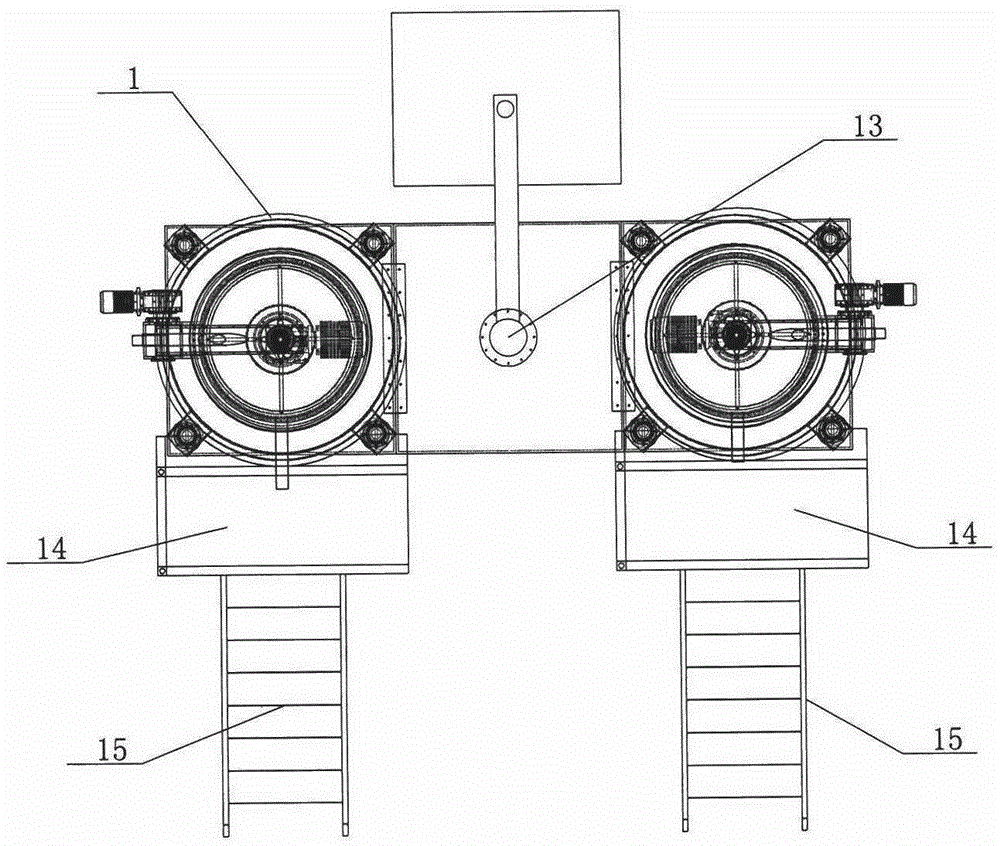

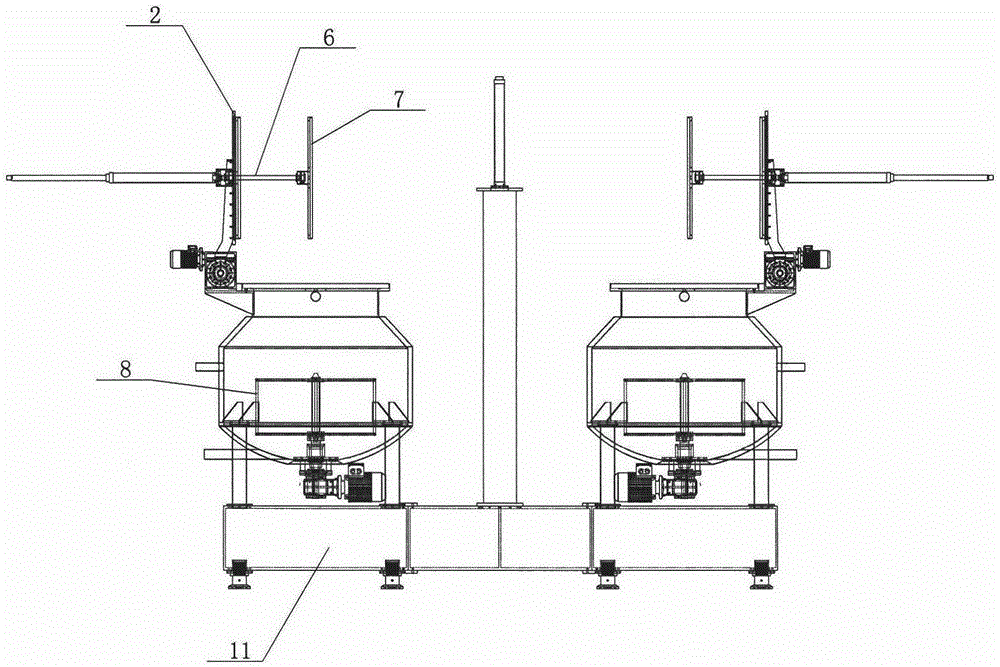

[0010] see Figure 1-3 , the specific embodiment adopts the following technical scheme: it comprises a tank body 1, a tank body upper cover 2, a rotating device 3, a first motor 4, a vertical shaft 5, a connecting shaft 6, a material column cover 7, a material column 8, a deoiling Assembly 9, second motor 10, support frame 11, connecting rod 12, manipulator 13, console 14 and ladder 15; the top of support frame 11 is provided with two tank bodies 1, and the top of tank body 1 is provided with tank body Cover 2, one side of the tank upper cover 2 is connected with the rotating device 3 through the connecting rod 12, the rotating device 3 is connected with the first motor 4, the upper part of the tank upper cover 2 is vertically provided with a vertical shaft 5, and the inside of the tank body 1 A material column 8 is provided, and the upper part of the material column 8 is provided with a material column cover 7, and the material column cover 7 is fixed on the tank body upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com