Method for producing no/n2 gaseous mixtures intended for the medical field

A technology for gaseous mixtures, mixtures, applied in the direction of mixing methods, gas and gas/vapor mixing, nitrogen compounds, etc., can solve problems such as high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

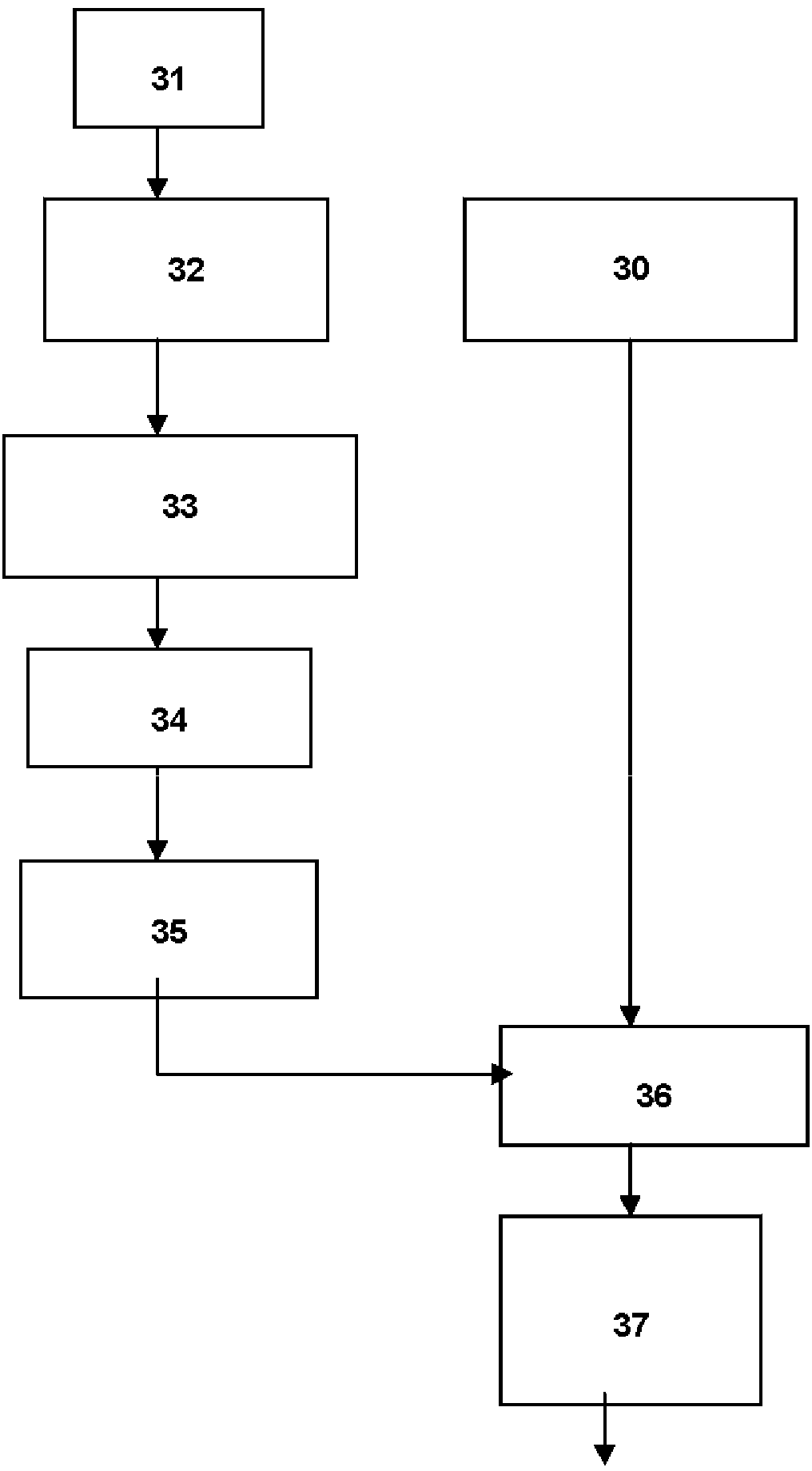

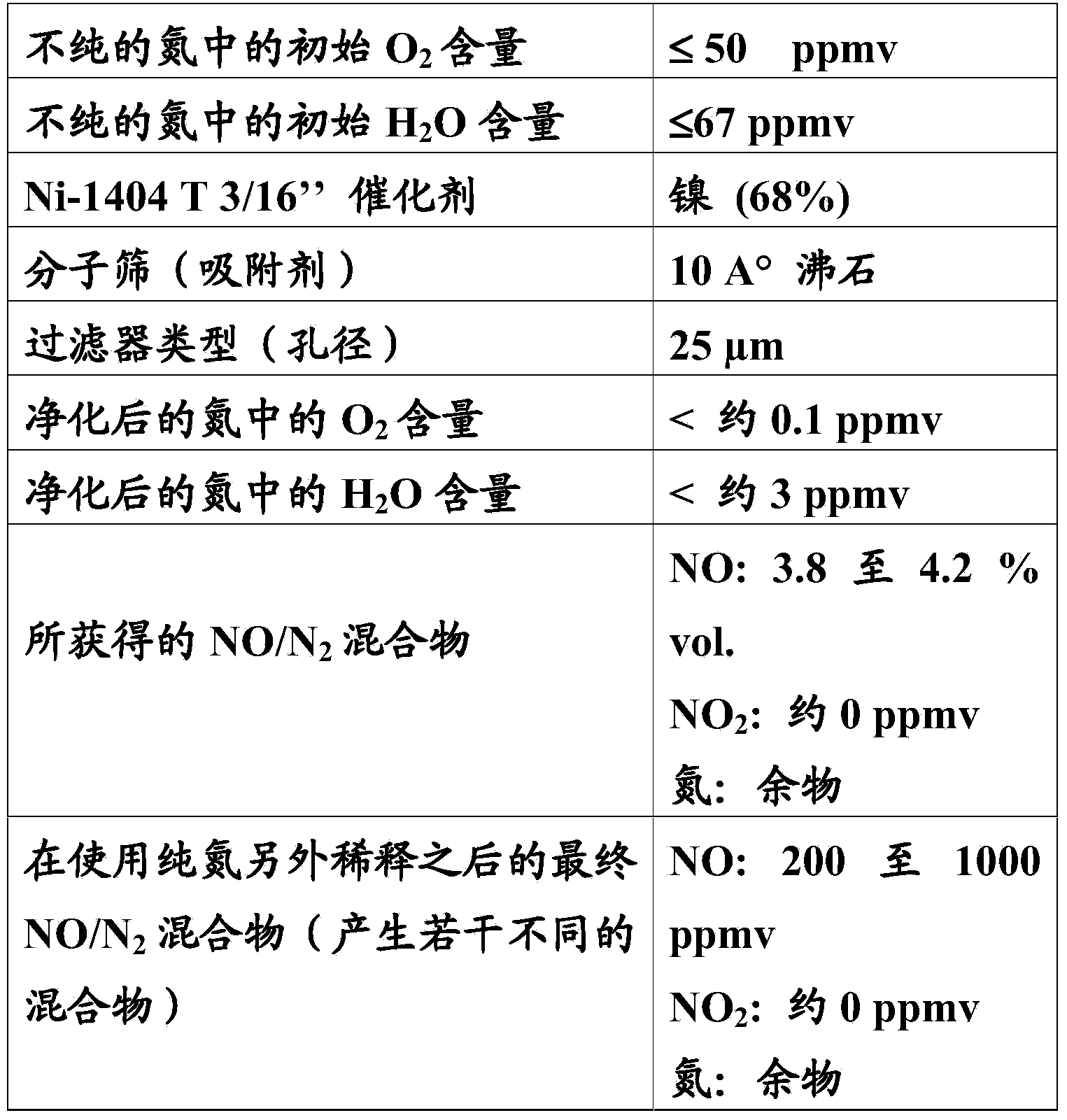

[0038] figure 1 Schematically shows an embodiment of the production method according to the invention, which produces no or almost no NO 2 NO / N of impurities 2 Gaseous mixtures, e.g. NO / N containing about 4% NO and nitrogen as remainder 2 gaseous mixture.

[0039] According to the method, the following successive steps are performed:

[0040] - (at 31) feeding impure nitrogen with the following composition: O 2 ≤50ppmv, CO≤5ppmv, CO 2 ≤300ppmv,H 2 O≤67ppmv, and N as remainder 2 (about 99.5%v)

[0041] - Purging of gaseous nitrogen containing the above-mentioned impurities is performed by the following steps:

[0042] i) (at 32) contacting the impure nitrogen with, for example, a nickel catalyst to eliminate or convert at least a portion of the O 2 type impurities, especially by converting them into water vapor or H 2 O,

[0043] ii) (at 33) contacting the nitrogen purified in sub-step i) with a molecular sieve such as 10A° zeolite to eliminate at least a portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com