Screw extrusion filtering type vacuum kneading machine

A vacuum kneader and screw extrusion technology, applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of equipment failure, seal damage, material extrusion, etc., and achieve convenient maintenance and cleaning , reduce production costs, and install firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

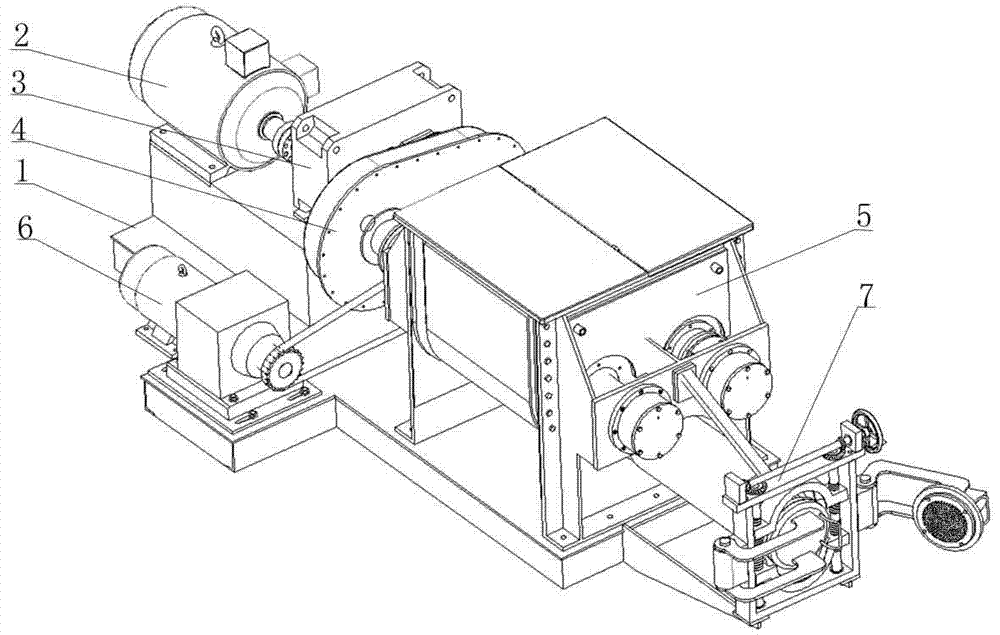

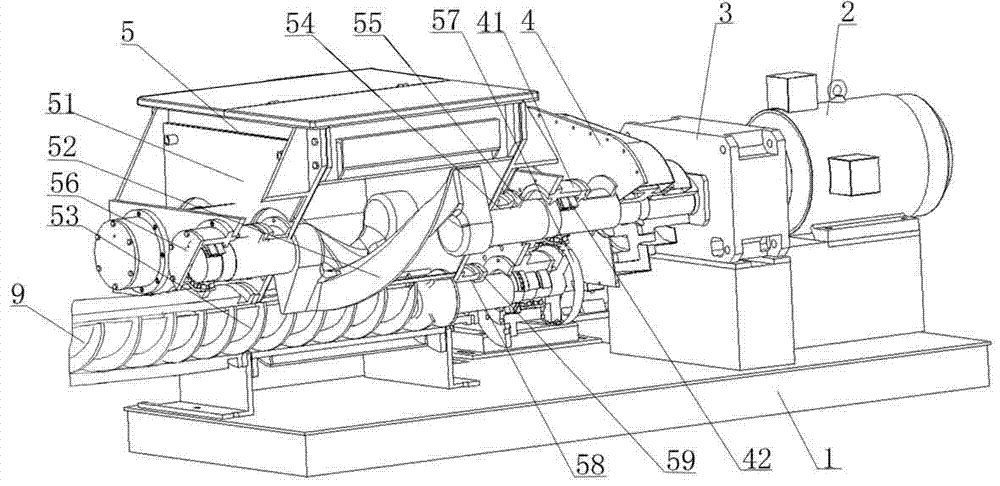

[0021] Refer to attached figure 1 , screw extrusion filter type vacuum kneader, which includes base 1, main motor 2, reducer 3, gear transmission mechanism 4, stirring extrusion mechanism 5, main motor 2 is installed behind the base 1, and the front end of the main motor 2 is driven and connected to decelerate Machine 3, the front end of the reducer 3 is driven and connected to the gear transmission mechanism 4, the front end of the gear transmission mechanism 4 is connected to the stirring and extruding mechanism 5, the stirring and extruding mechanism 5 is installed on the upper end of the base 1, and the front end of the stirring and extruding mechanism 5 is equipped with an extrusion filter device 7 .

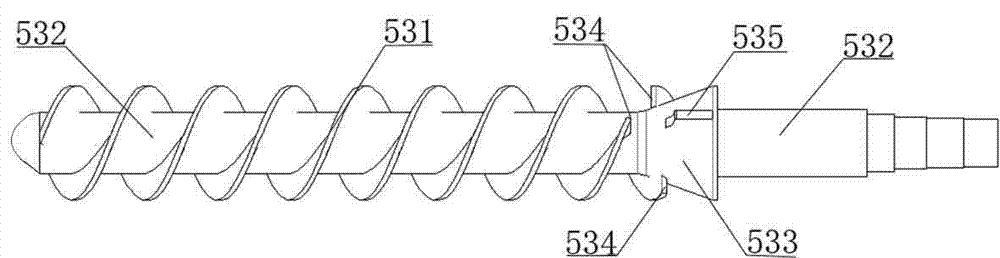

[0022] The stirring and extruding mechanism 5 includes a stirring cylinder 51, a stirring paddle 52, and a screw rod 53. There are two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com