Large flow assembled grinding device for nano sand mill

A grinding device and a sand mill technology, which are used in the field of mixing and dispersing solid powder and liquid, homogenizing, large-flow assembled grinding rotor device, and emulsification, which can solve the problem of high replacement and maintenance costs, and the inability to manufacture large Diameter and large structure size, small grinding energy and other problems, to achieve the effect of improving production efficiency and production quality, stable and efficient grinding process, and good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

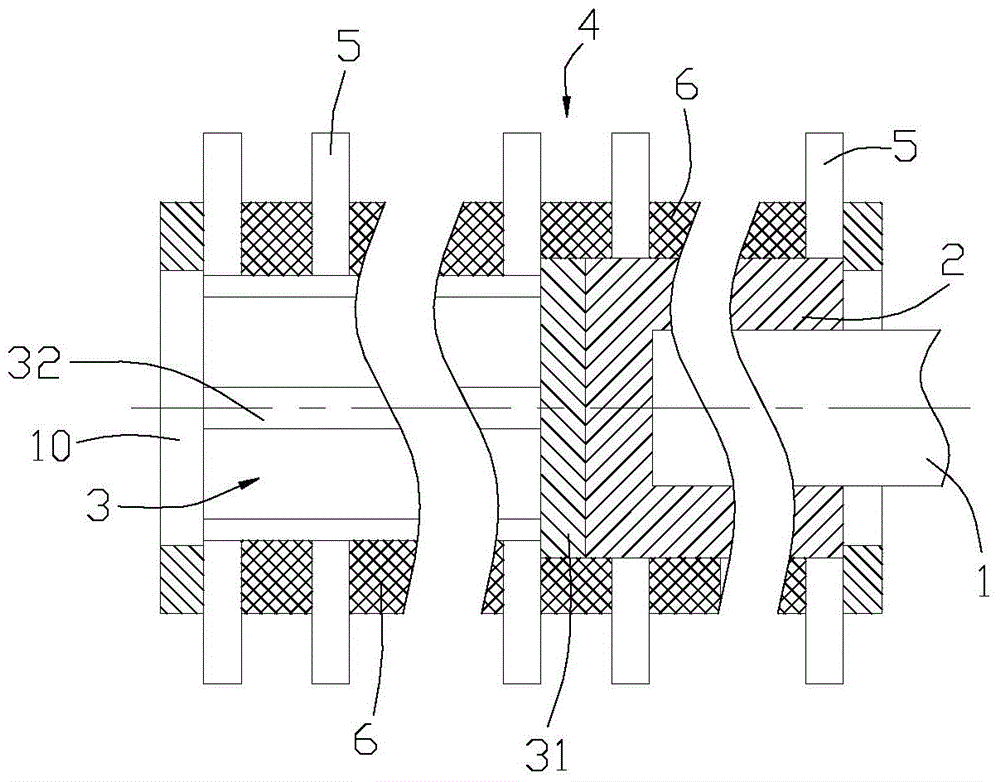

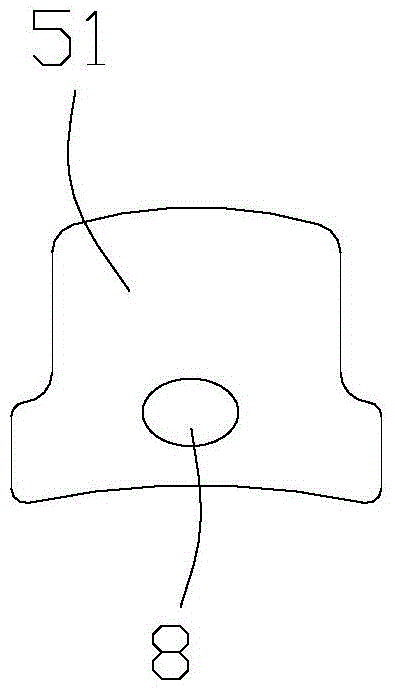

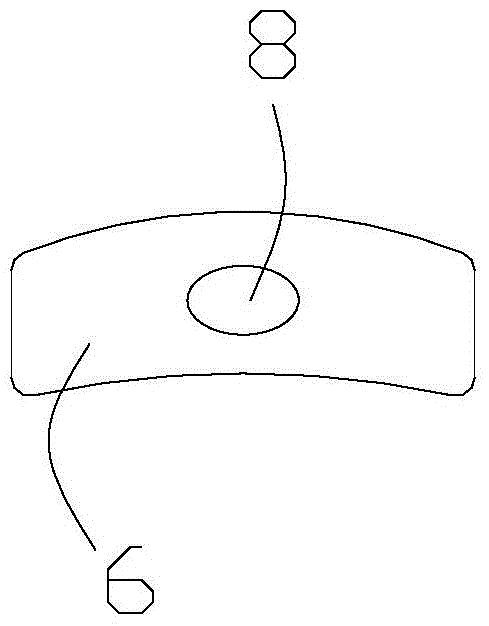

[0022] Such as figure 1 , the grinding rotor of the present invention includes a rotating core 2 that is connected to the main shaft 1 at one end and driven to rotate by the main shaft. The other end of the rotating core is fixed with a hollow grinding frame 3, and a separator is arranged in the grinding frame. The rotating core and the grinding frame form a concentric The rotating body 4 with the same diameter, the rotating core drives the grinding frame to rotate, and several rows of detachable grinding blocks 5 are installed on the peripheral wall of the rotating body along the circumferential direction, and detachable grinding blocks 5 are installed between two adjacent grinding blocks in each row. Isolation block 6; a feed opening is formed between every adjacent two rows of grinding blocks on the grinding rack, and the feeding opening communicates with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com