Eccentric winding mechanism of glass fiber covered wires

A wire-wrapped, eccentric technology, applied in the field of eccentric wrapping mechanisms for glass-wrapped wires, can solve the problems affecting the bending resistance of glass-wrapped wires, poor wire-bending capacity, and small concentric wrapping pitch. Good, slow winding speed, small wrapping pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

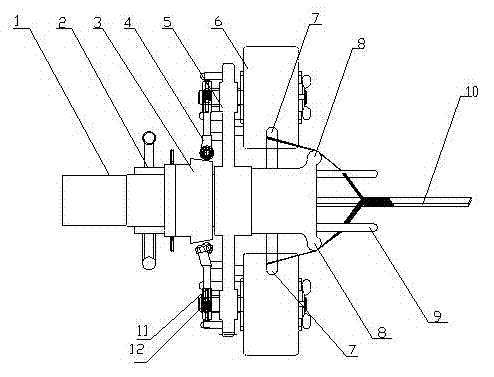

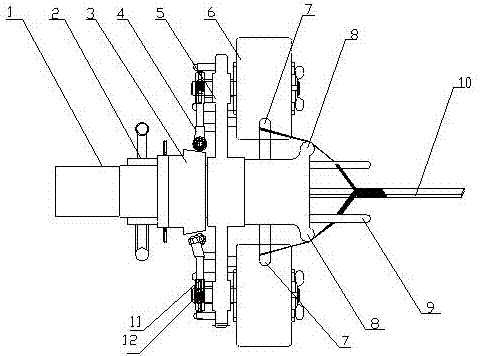

[0012] Hereinafter, in conjunction with the drawings and preferred embodiments, the specific implementation manners and features provided according to the present invention are described in detail as follows:

[0013] Such as figure 1 As shown, a glass fiber covered wire eccentric wrapping mechanism includes a hollow shaft 1, an adjusting tension hand wheel 2, an adjusting tension cone disk 3, a tension lever 4, a planetary disk 5 (synchronous wheel), a yarn spreading ring 7, The yarn spreading disc 8, the spreading wire rod 9, the friction block 11 and the friction roller 12; the tension adjusting hand wheel 2 and the hollow shaft 1 are connected by concentric threads; the tension adjusting cone 3 is concentrically located at the front end of the tension adjusting hand wheel 2, It is connected with the hollow shaft 1 for bearing connection and rotation; the planetary disk 5 is concentrically located at the front end of the tension adjustment cone 3 and is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com