Automatic tube insertion machine and process for condenser and evaporator fins of air conditioner

An air conditioner condenser and evaporator technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor cost, low productivity, jamming, etc., to improve production efficiency and product quality, reduce manpower and material resources , the effect of fast and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

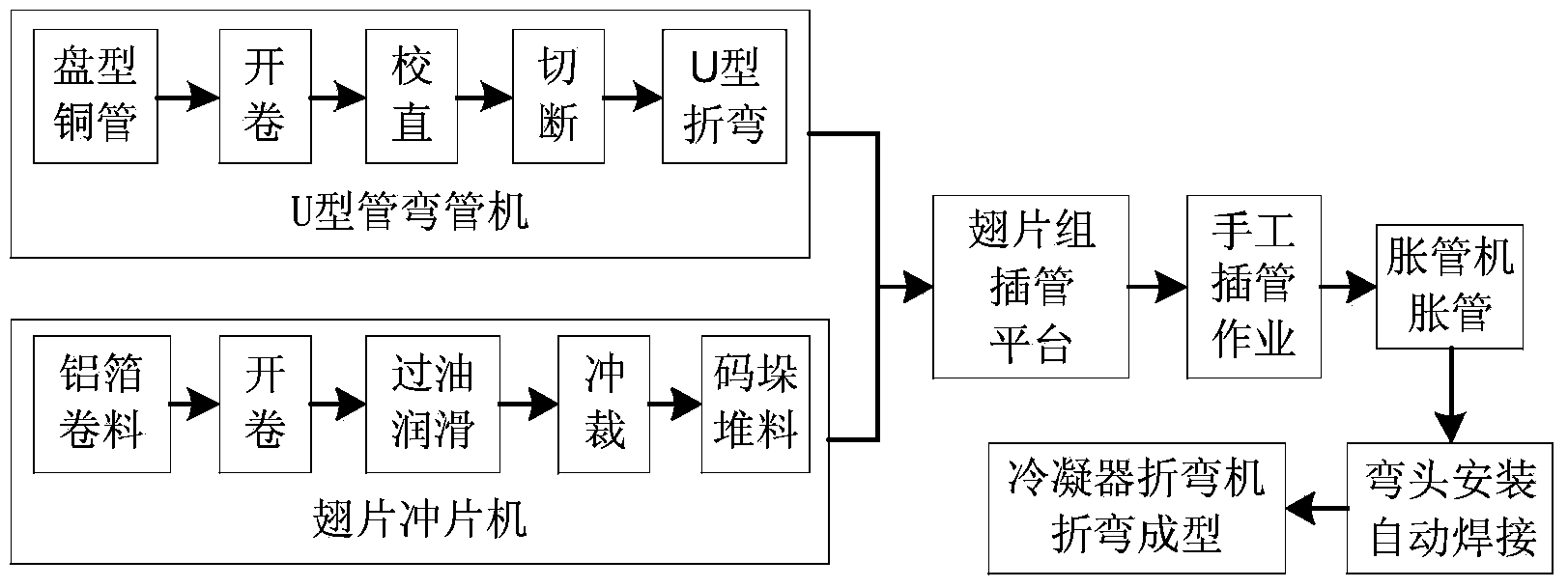

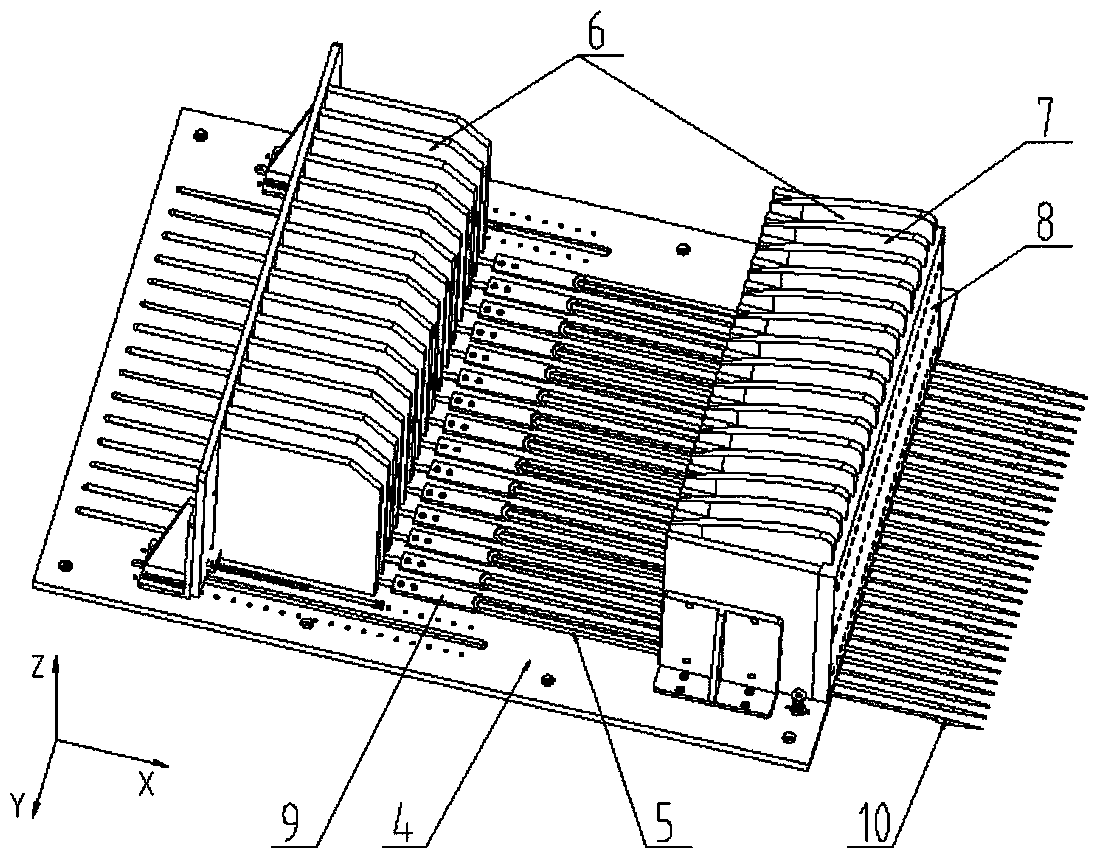

[0056] Such as Figure 1 to Figure 8 As shown, an automatic fin insertion machine for air-conditioning condensers and evaporators includes a frame 25 and two U-shaped tube feeding and positioning devices arranged side by side on the frame from left to right, and fins A group of feeding and positioning devices and two side-by-side automatic alignment and circulation feeding devices for guiding pins, the two U-shaped tube feeding and positioning devices and two automatic alignment and circulation feeding devices for guiding pins are parallel and symmetrical Set both sides of the rack 25;

[0057] The U-shaped tube feeding and positioning device includes a base plate 4, a U-shaped tube swing mechanism 6 and a profiling tube pushing mechanism 9, and the U-shaped tube swinging mechanism 6 and the profiling tube pushing mechanism 9 are fixedly arranged on the base plate 4, the base plate 4 is provided with an adjustment hole, which is used to adjust the position of the U-shaped tub...

Embodiment 2

[0063] An automatic fin insertion machine for air conditioner condensers and evaporators, the structure of which is as described in Embodiment 1, the difference is that the pinch groove is set as a V-shaped pinch groove.

Embodiment 3

[0065] Such as Figure 9 Shown, a kind of automatic intubation process of above-mentioned air-conditioning condenser and evaporator fin automatic intubation machine, comprises the following steps,

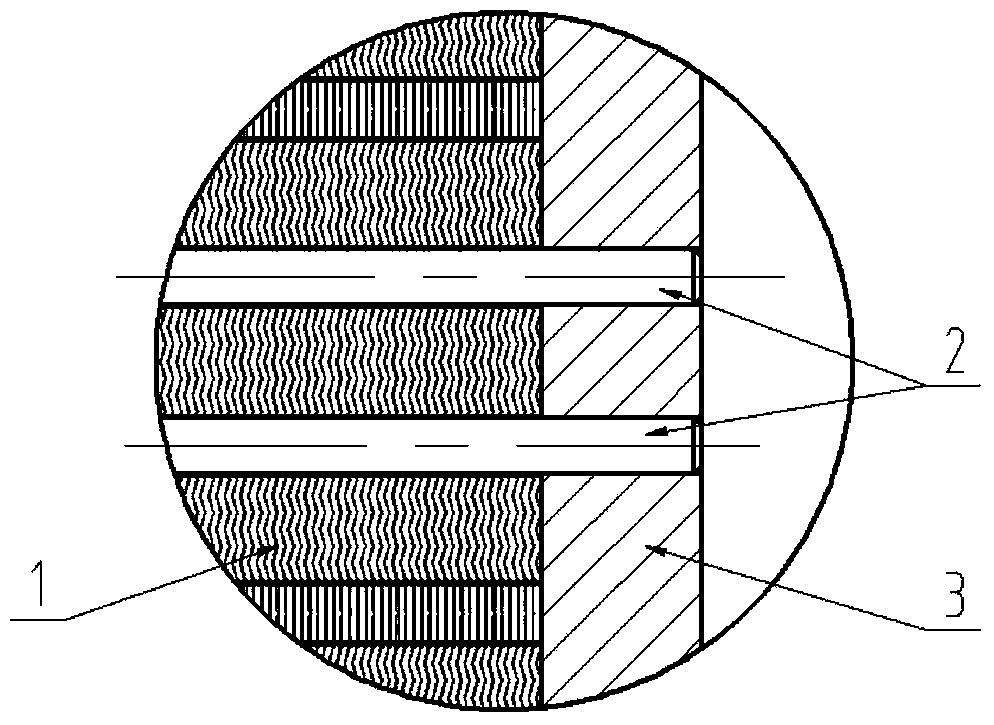

[0066] (1) The fin group 29 formed by stacking the fins of the fin punching machine uses two long tapered guide pins 2 and the positioning baffle 3 to carry out "two holes on one side" positioning, and the positioned fin group 29 is placed on the Fin group motion platform 30;

[0067] (2) Put the formed U-shaped tube 5 bulk material into the U-shaped tube feeding and positioning device of the first station and the second station to swing the tube, and use the U-shaped tube Y-direction correction plate 7 and the U-shaped tube The Z-direction correction plate 8 guides and positions the U-shaped pipe 5;

[0068] (3) The pilot pin automatic alignment and circulation feeding device 31 and the pilot pin automatic alignment and circulation feeding device 32 arrange the pilot pins 10 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com