split nozzle

A split-type, nozzle technology, applied in the field of 3D printer accessories, can solve problems such as affecting the accuracy of 3D printers, large nozzle motion inertia, slowing down printing speed, etc., to ensure smooth transmission, improve printing quality, and reduce the effect of load inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

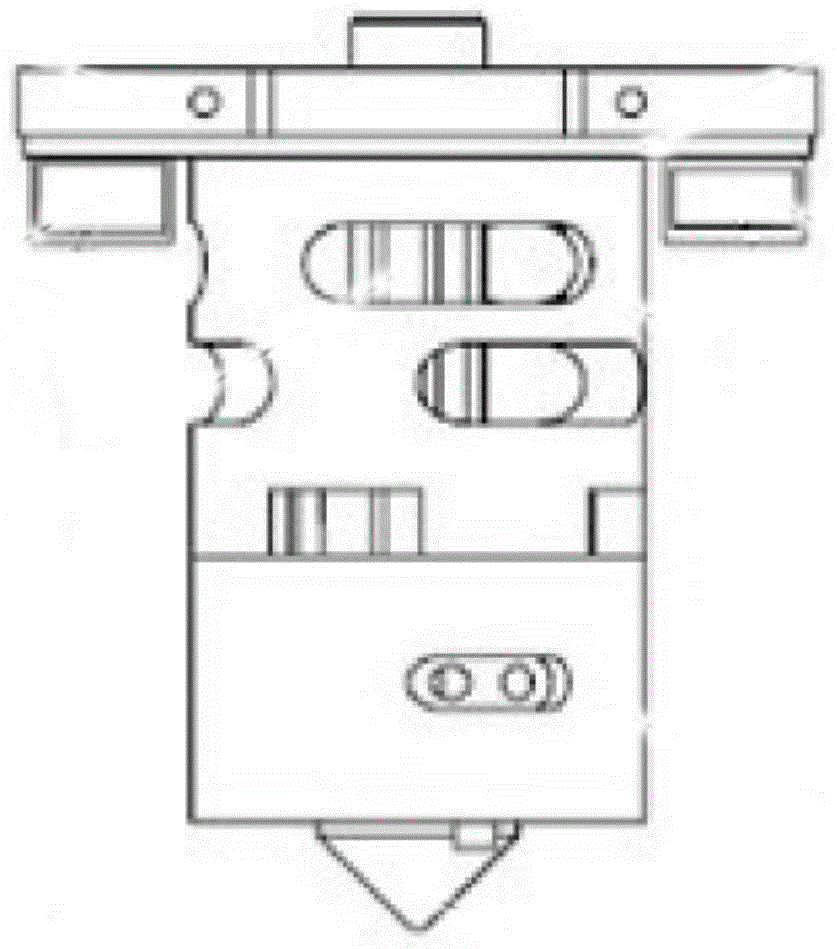

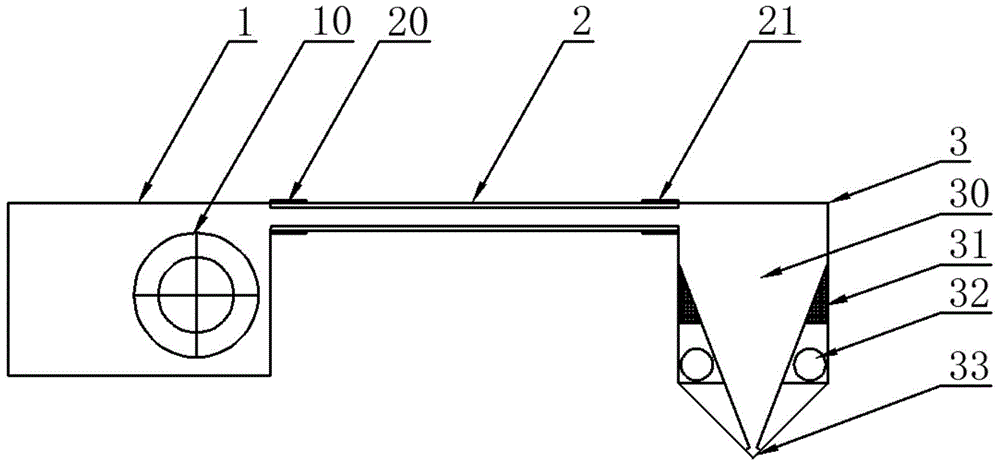

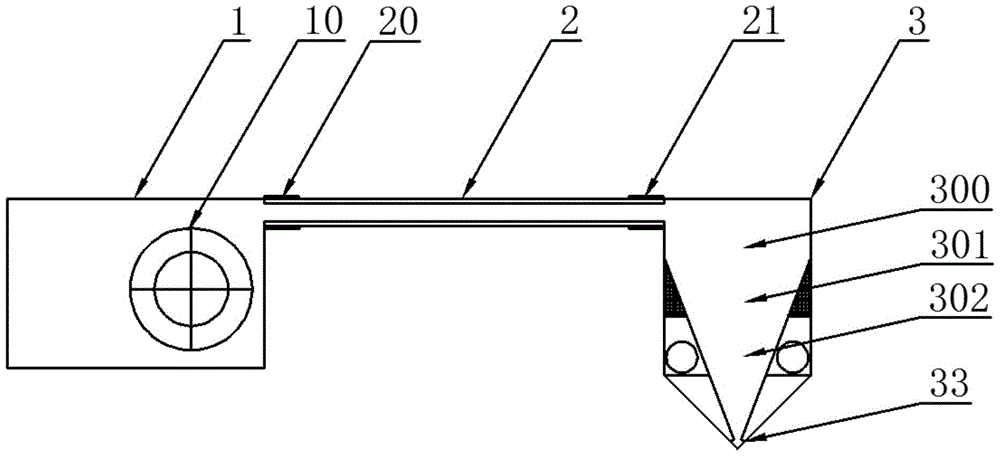

[0025] Such as figure 2 , 3 As shown, the split nozzle includes a feeder 1, a wire feeding tube 2 and a moving nozzle 3, and the feeder 1 and the moving nozzle 3 are connected through the wire feeding tube 2; the moving nozzle 3 includes a cavity 30 and a cooling fin 31 , a thermocouple 32 and a nozzle 33, the lower end of the cavity 30 is fixedly connected to the nozzle 33, a cooling fin 31 is fixed in the center of the outer side of the cavity 30, and a thermocouple 32 is arranged on the outer side of the cavity 30, between the cooling fin 31 and the nozzle 33, and the thermocouple 32 is fixedly connected with the cavity 30.

[0026] The movable nozzle 3 is installed on the motion shaft of the 3D printer, and is used for heating and melting the printing material and extruding the printing material during printing, and is responsible for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com