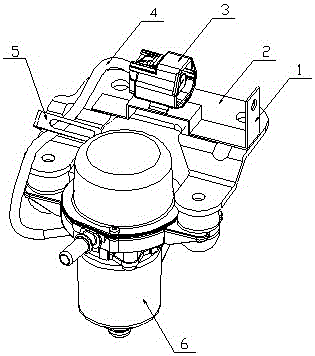

An electronic vacuum pump mounting bracket

A technology for electronic vacuum pumps and mounting brackets, which is applied to the layout of pumps/compressors, etc., can solve the problems of inability to achieve vibration and noise reduction, inability to achieve first-level assembly, and affecting comfort, etc., to achieve easy assembly and the best vibration reduction performance The effect of optimization and structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The electronic vacuum pump bracket involved in the present invention has the characteristics of simple structure, small space occupation, simple molding process, and low manufacturing cost. This article does not explain it, but mainly focuses on its functions of attenuating vibration and noise and integrating wiring harness layout.

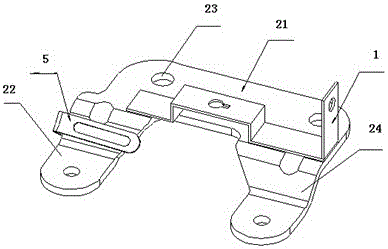

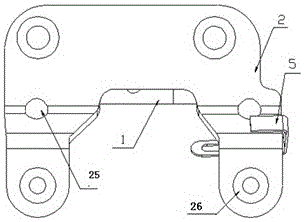

[0020] see figure 2 and image 3 , The bracket involved in the present invention is composed of a bracket body 2, a "several" character bracket 1, a line card 5 and a vibration damping washer 8 in four parts. The bracket body 2 is composed of two parts, one is a flat connecting portion 21 and the other is a mounting ear 22 . Two bolt mounting holes 23 are provided on the flat connecting portion 21 for connecting and fixing the bracket with the vehicle body or the transmission housing. A mounting ear 22 is respectively provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com