Automobile with special steel-aluminum section connecting pieces

A technology for connecting parts and aluminum profiles, which is used in the connection between the superstructure sub-assemblies, vehicle components, and superstructures, etc., can solve the problems of high cost and low strength, and achieve a simple connection method, low cost, and scope of application. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

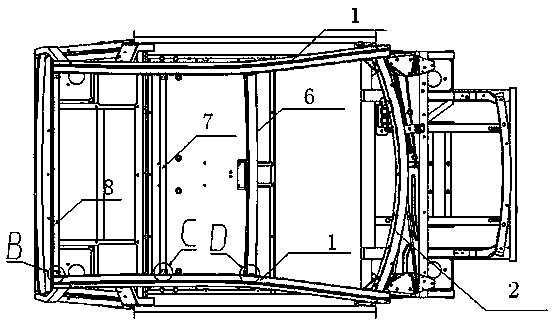

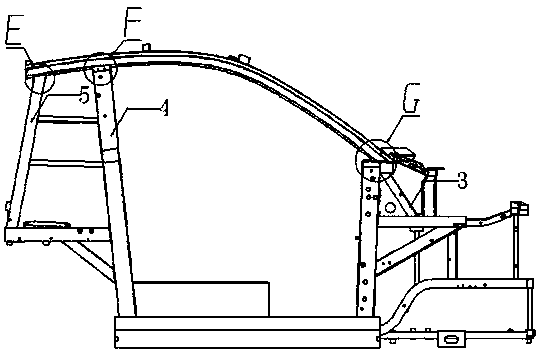

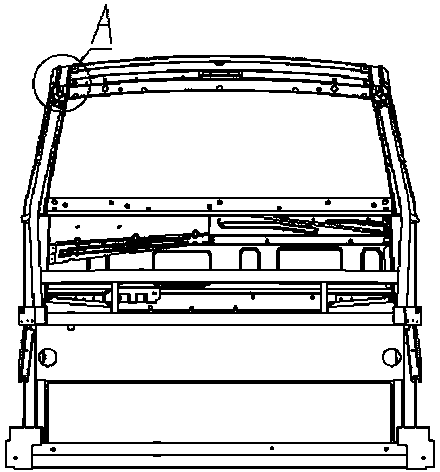

[0037]The present invention will be further described below in conjunction with accompanying drawing and embodiment, and a kind of automobile that the present invention discloses has special-made steel-aluminum profile connector, comprises vehicle frame, vehicle body; Beam 1, front windshield lower crossbeam 2, roof side beam 1, front windshield lower crossbeam 2; the vehicle body includes: A-pillar 3, B-pillar 4, C-pillar 5, front beam 6 prepared from steel profiles , the middle beam 7, the rear beam 8; it is characterized in that: a first connecting piece is arranged between the roof side beam 1 and the front beam 6; the first connecting piece is connected to the roof side beam 1 The other end of the first connecting piece is provided with a screw hole, and is connected with the front beam 6 by bolts; the roof side beam 1 and the A-pillar 3 are provided with a second connection The second connecting piece is welded to the side beam 1 of the top cover, and the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com