A paper corner strip stacking platform binding device

A technology of a binding device and a stacking platform, which is applied in the field of binding and stacking paper corner strips, can solve the problems of low production efficiency and high labor intensity, and achieve the effects of low manufacturing cost, reduced labor intensity, and favorable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

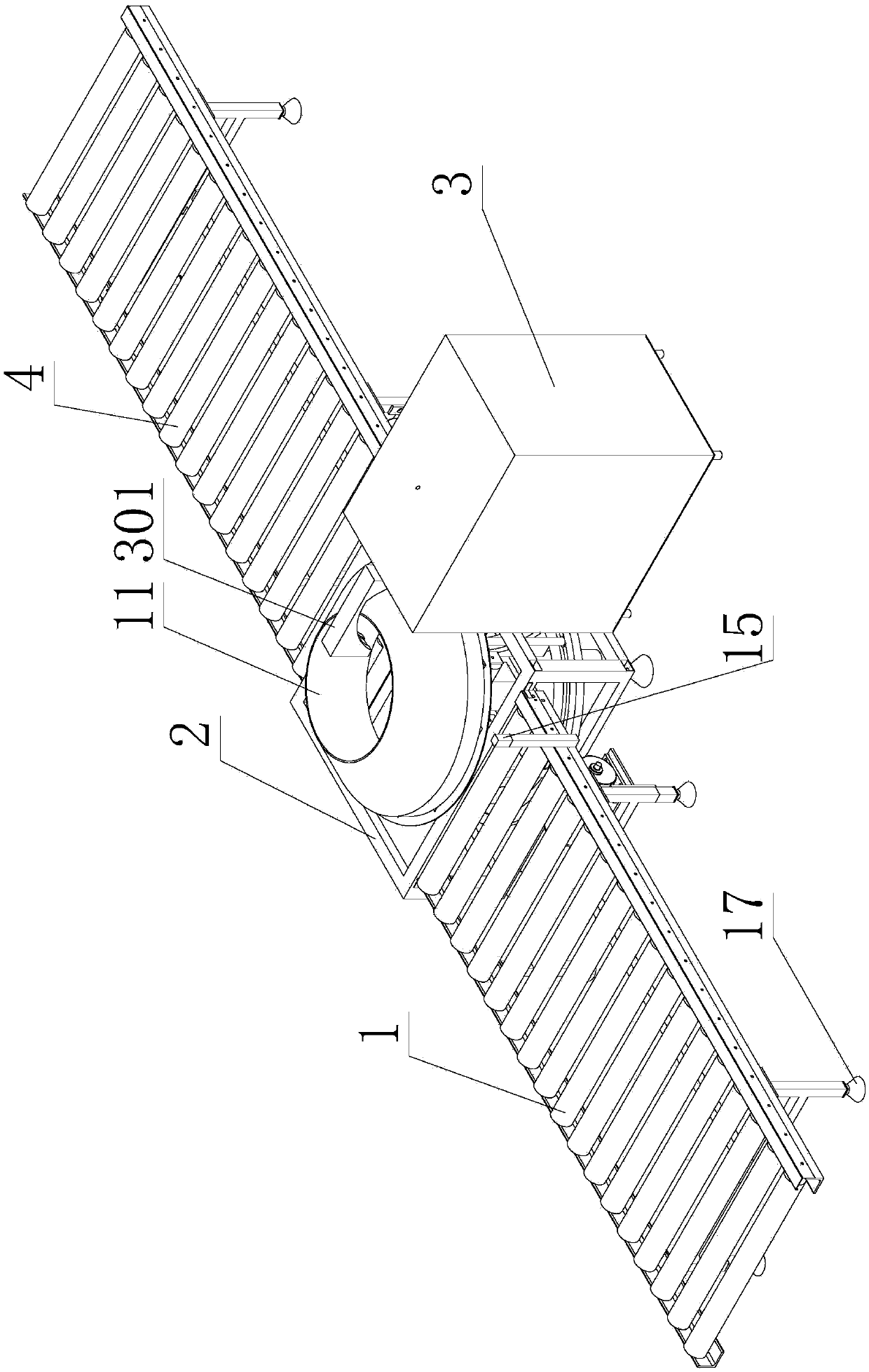

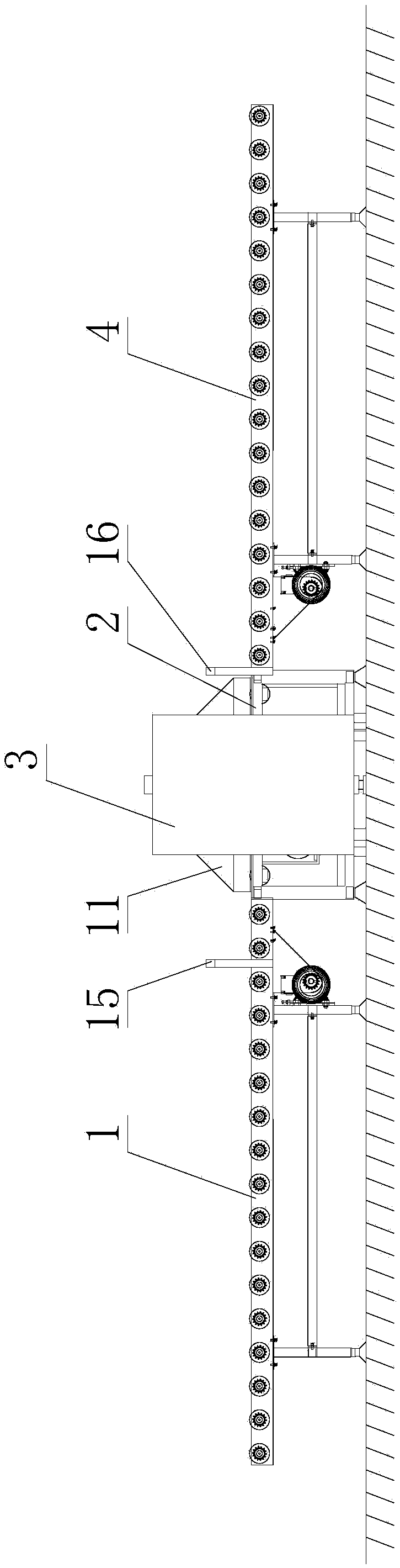

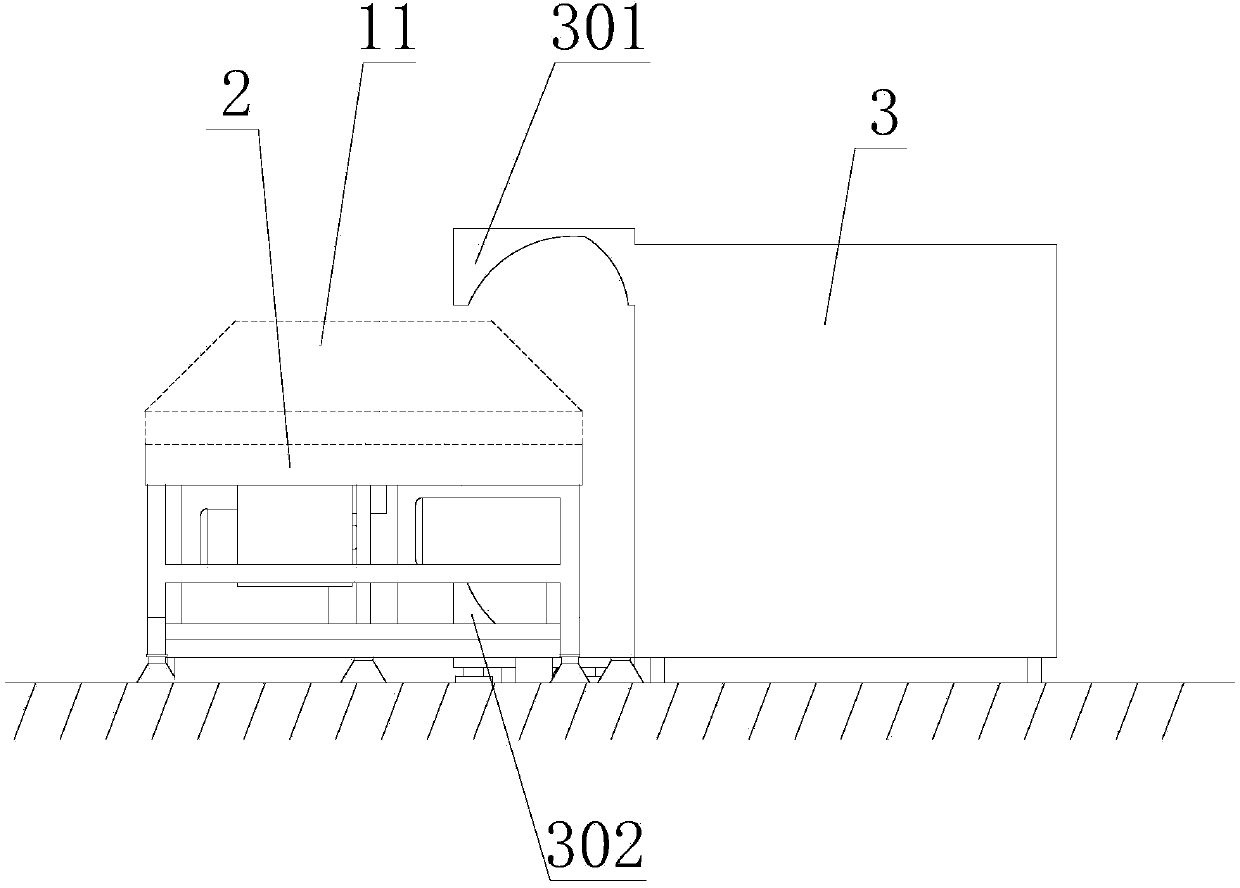

[0044] The present invention will be further described below in conjunction with accompanying drawing.

[0045] Such as Figure 5 As shown, the rotary strapping platform 2 includes a hollow square base 5 and an octagonal rotating disk 6 horizontally arranged at the center above the base 5, and two ropes are opened from the two sides of the rotating disk 6 toward the center. mouth 8, a vertical rotating shaft 9 is fixed at the center of the lower surface of the rotating disk 6 between the two rope openings 8, the lower end of the rotating shaft 9 is driven by the first motor installed in the inner frame of the base 5, and can rotate around its own axis Rotate, the rotation angle of rotating shaft is positive and negative 180 °.

[0046] Between the two rope passages 8, two horizontal installation frame bars 10 are arranged at intervals perpendicular to the length direction. The installation frame bar 10 is an angle iron bent at 90°, and its vertical lower end is fixed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com