180-degree slewing bend

A technology of curve and inner diameter, which is applied in the field of transmission devices, can solve the problems of large demand, shortened service life, complicated bearing force condition, etc., and achieves the effect of small power and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

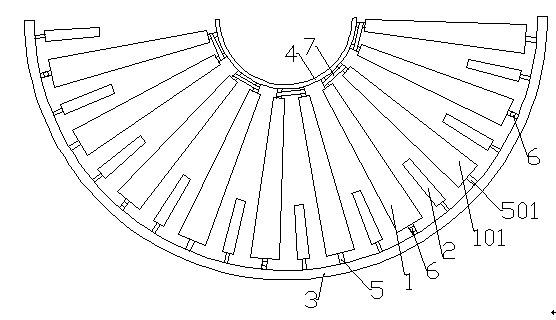

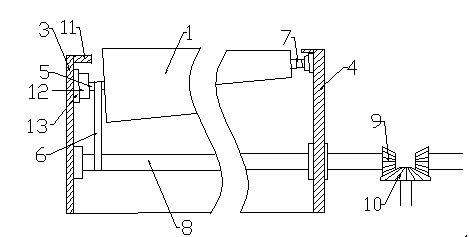

[0014] The specific embodiment of the present invention is described in conjunction with accompanying drawing, as figure 1 and figure 2 As shown, the 180-degree turning curve includes an outer diameter support 3 and an inner diameter support 4. The outer diameter support 3 and the inner diameter support 4 are concentric arcs, and also includes a plurality of roller sets. One of the roller sets is the driving roller 1, and the other It is the driven roller 101, the driving roller 1 and the driven roller 101 are the same tapered rollers, the driving roller 1 is installed on the outer diameter bracket 3 and the inner diameter bracket 4 through the shaft 5, and the driven roller 101 is passed through the driven shaft 501 Between them, the tapered rollers are arranged radially, and the center of the radiation is concentric with the outer diameter support 3; the shaft 5 and the driven shaft 501 are installed obliquely between the outer diameter support 3 and the inner diameter supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com