Ceramic ferrule direction adjustment mechanism

A technology of ceramic ferrule and direction adjustment, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of the influence of size error, high discrimination error rate, and high equipment cost, and achieve high consistency of adjustment direction and fast adjustment speed. , cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

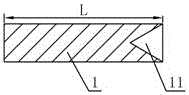

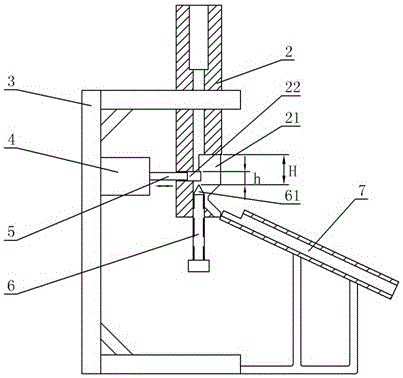

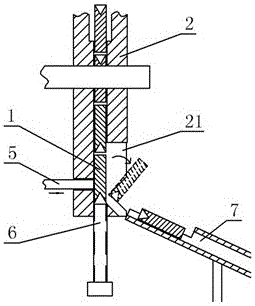

[0021] Such as figure 2 The shown ceramic ferrule direction adjustment mechanism includes a feeding pipe 2, a bracket 3, a cylinder 4, a push rod 5, a tip 6, and a feeding pipe 7.

[0022] The feeding pipe 2 is fixed on the upper part of the bracket 3, the feeding pipe 2 is vertically arranged, and there is a vertical pipe inside which the ceramic ferrule can pass through, and a plurality of ceramic ferrules can move along the pipeline in the feeding pipe 2 under the action of gravity. The bottom slides down, and the lower side wall of the feed pipe 2 has a discharge gap 21. The lower end of the feed pipe 2 is threaded to fix the tip 6, the tip 61 is upward and is located in the inner pipeline of the feed tube 2, and the tip 61 is facing the discharge gap 21, and the tip 61 can be inserted into the bottom of the bell mouth 11.

[0023] In order to ensure that the discharge gap 21 can only turn over one ceramic ferrule at a time, the distance H between the upper edge of the d...

Embodiment 2

[0032] Such as Figure 5 , Figure 6 The shown ceramic ferrule direction adjustment mechanism includes a feeding pipe 2, a bracket 3, a motor 8, a runner 9, a tip 6, and a feeding pipe 7.

[0033] Wherein, the structures of the bracket 3, the tip 6, and the material receiving pipe 7 are the same as those in the first embodiment.

[0034] The motor 8 is fixed to the support, and the rotating shaft of the motor 8 is fixed with a runner 9, and the runner 9 has a plurality of gear teeth 91 distributed in an array.

[0035] In order not to damage the ceramic ferrule when colliding, there is a transition arc between at least one outer edge of the gear tooth 91 and the outer edge of other parts of the runner 9, that is, when the runner 9 contacts the ceramic ferrule, the ceramic ferrule moves along the The smooth arc gradually touches the highest point of the gear teeth 91, such as Figure 6 shown.

[0036] There is a fan-shaped channel 23 on the side wall of the feed pipe 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com