Method for adjusting a rotation angle position of a coil frame and textile machines for producing coils

A creel and rotation angle technology, which is applied in the directions of transportation and packaging, thin material handling, and conveying filamentous materials, etc., can solve the problem of inability to accurately inspect the creel, and achieve the effect of easy visual inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

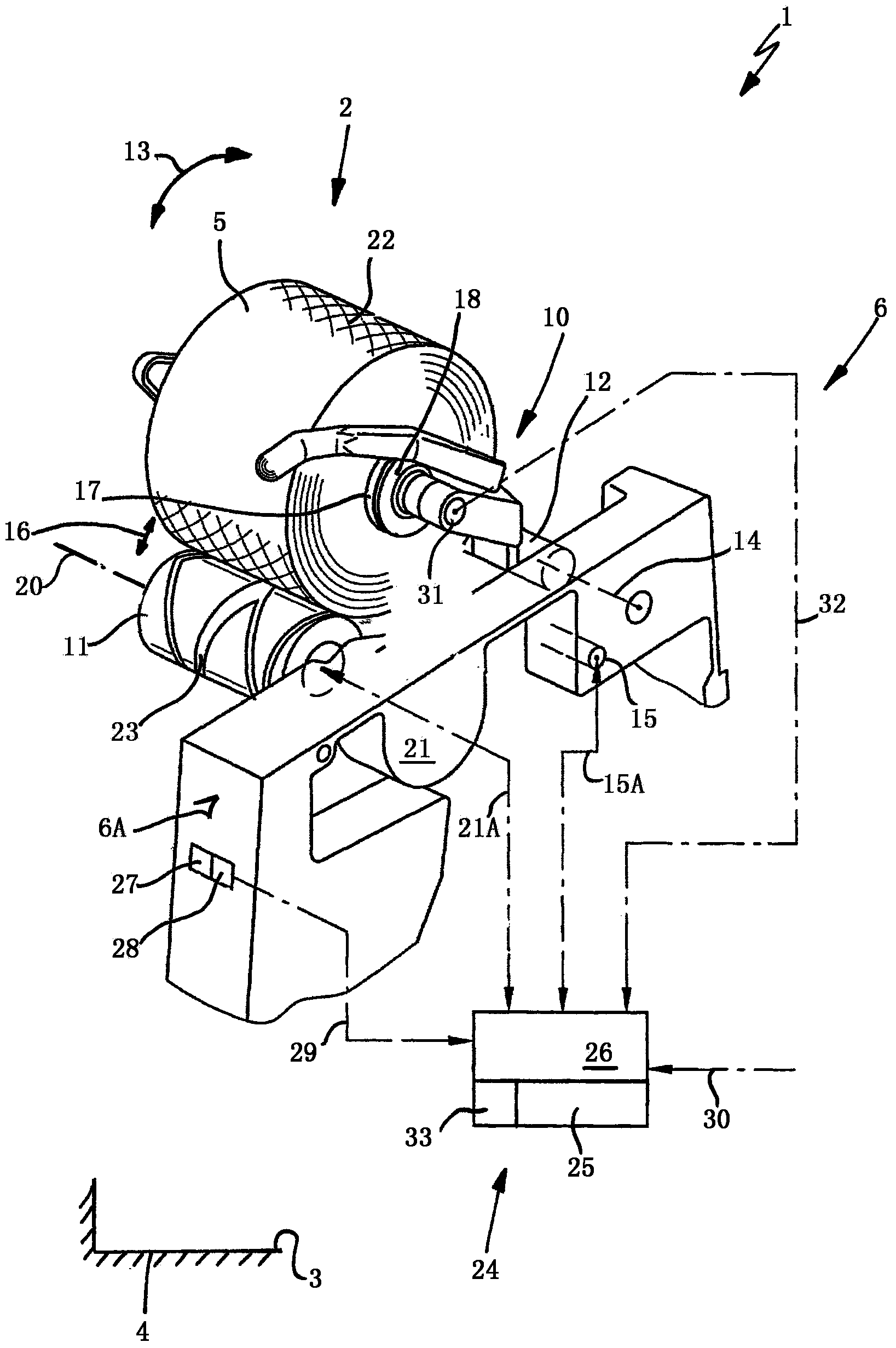

[0099] In this single figure, a winder 1 in a textile machine 3 for producing bobbins 2 is shown schematically, which has a plurality of such winders 1 in it.

[0100] The textile machine 3 for producing bobbins 2 shown in this embodiment is in particular a winding machine 4 for producing cross-wound bobbins 5 .

[0101] Each winding head 1 comprises a support frame 6 on which a creel 10 and a drive roller 11 are mounted.

[0102] For this purpose, a creel 10 is pivotably mounted on the support frame 6 about a pivot axis 14 according to the direction of rotation 13 by means of a swivel mount 12 in the form of a mount shaft and can be driven by a stepper motor 15 . In this respect, the creel 10 driven by the motor can be moved towards or placed on the drive roller 11 or moved or lifted away from the drive roller 11 . Here, the creel 10 must be adjustable relative to the drive roller 11 according to the bobbin diameter which also increases during the bobbin stroke.

[0103] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com