Up-conversion composite material modified by cyclodextrin derivatives and its preparation method and application

A composite material, cyclodextrin technology, applied in analytical materials, luminescent materials, material excitation analysis, etc., can solve the problem of unreported cholesterol-selective fluorescent probes, eliminate background fluorescence interference, improve signal-to-noise ratio, The effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

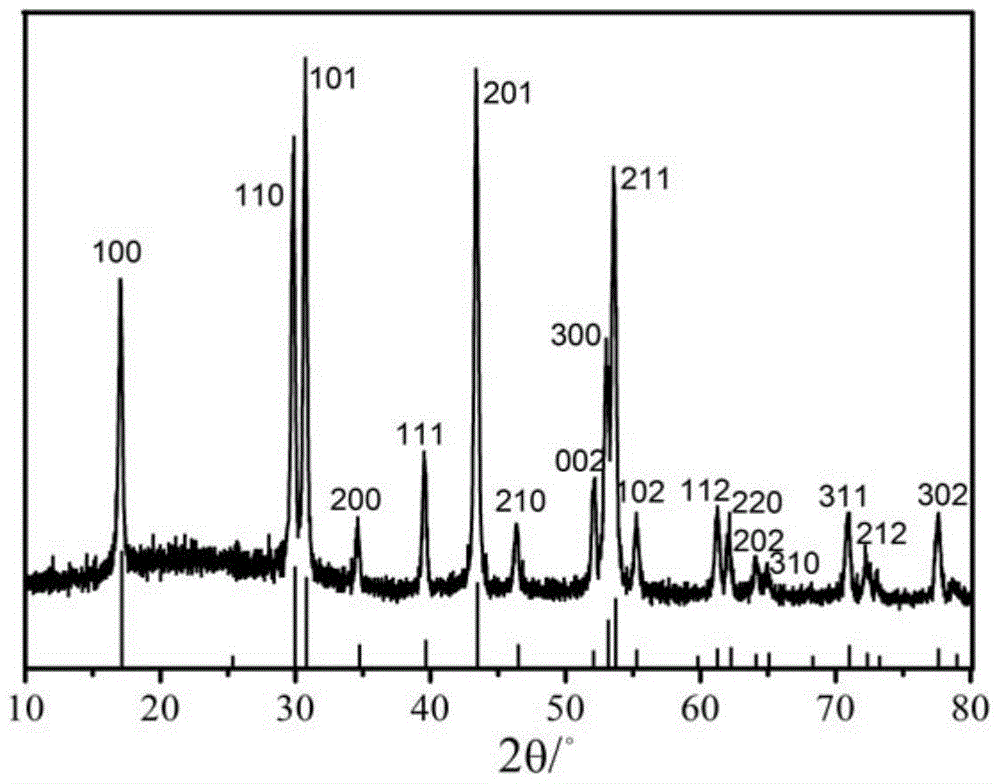

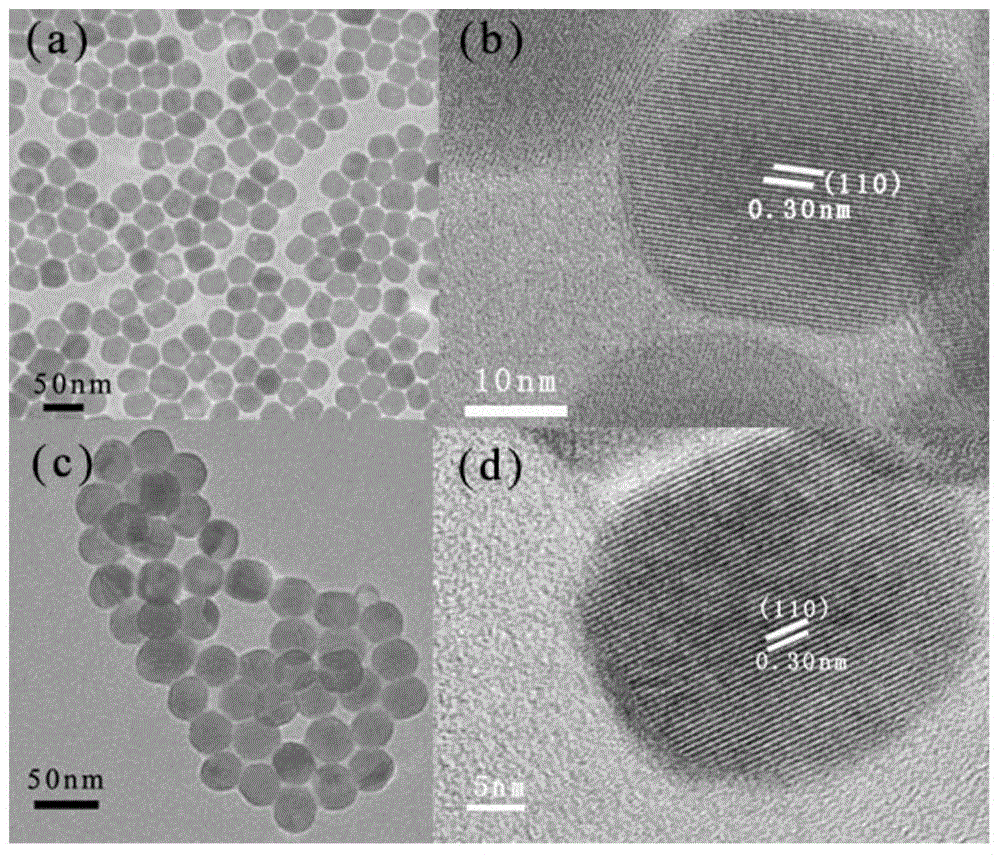

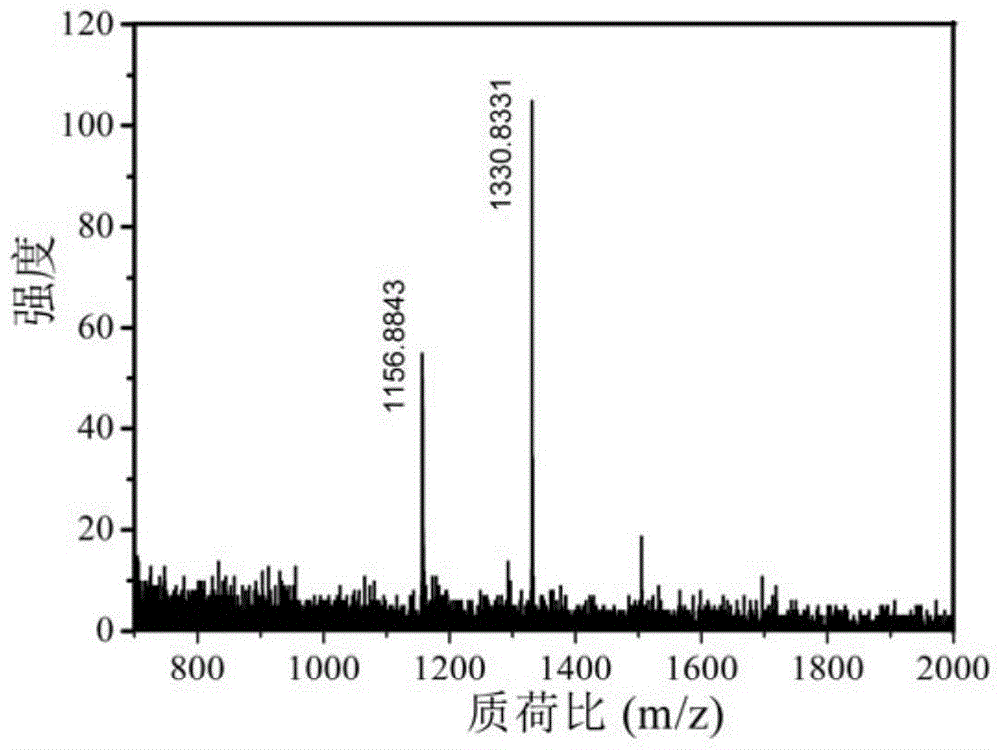

[0032] Example 1. Preparation of Upconversion Composite Materials Modified by Cyclodextrin Derivatives

[0033] Step 1. With 1mmol RECl 3 (0.78mmol YCl 3 ,0.2mmol YbCl 3 ,0.02mmol ErCl 3 ) as the reaction raw materials, add 7.5mL oleic acid and 17.5mL 1-octadecene, stir evenly, and heat the solution to 160°C for 30min. Cool to room temperature, add 4mmol NH 4 F and 2.5mmol NaOH in methanol solution, stirred for 30min. Methanol was evaporated, and the solution was heated to 300° C. under the protection of argon, reacted for 1 h, and cooled to room temperature. The reaction solution was precipitated by adding ethanol, centrifuged, washed with water and ethanol several times to obtain a white precipitate, namely OA-UCNPs;

[0034] Step 2. Disperse 100 mg of OA-UCNPs in 10 mL of aqueous solution, add 0.1 M hydrochloric acid solution dropwise until pH = 4, and stir at room temperature for 4 h. Centrifuge and wash several times with ethanol aqueous solution to obtain ligand-f...

Embodiment 2

[0038] Example 2. Preparation of Upconversion Composite Materials Modified by Cyclodextrin Derivatives

[0039] The up-conversion composite material modified by cyclodextrin derivatives was prepared according to the steps of Example 1, but NH 4 The amount of substance F was 1.6 and 2.8 mmol, respectively, and the other steps were the same. Result is with embodiment 1.

Embodiment 3

[0040] Example 3. Preparation of Upconversion Composite Materials Modified by Cyclodextrin Derivatives

[0041] The upconversion composite material modified by cyclodextrin derivatives was prepared according to the steps of Example 1, but in step 1, the solution was heated to 280° C. under the protection of argon, and the other steps were the same. Result is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com