Magnetorheological fluid special for optical glass polishing and preparation method thereof

A technology of magnetorheological fluid and optical glass, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of subsurface damage and low efficiency of polishing processing, so as to avoid damage to the human body, expand feasibility, and reduce hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

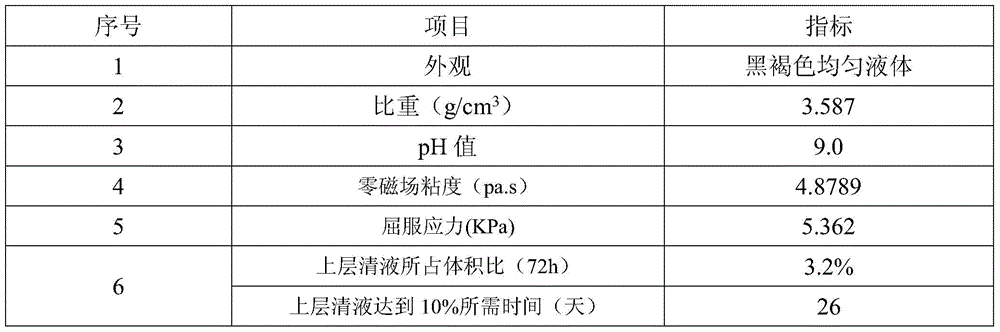

Embodiment 1

[0020] A method for preparing a special magnetorheological fluid for optical glass polishing, comprising the following steps:

[0021] (1) Take the following components by weight percentage: 70% of carbonyl iron powder, 10% of diamond particles with a particle diameter of 40 μm, 2% of sodium carboxymethyl cellulose, 2% of sodium carbonate, polyethylene glycol 6001%, Triethanolamine 0.5%, potassium tetraborate 0.5%, benzotriazole 0.6%, hexamethylenetetramine 0.6%, purified water 12.8%;

[0022] (2) At room temperature, add sodium carbonate to water and stir to dissolve; heat, at 60°C, add potassium tetraborate while stirring to dissolve, add benzotriazole to dissolve, add hexamethylenetetra Amine is dissolved, triethanolamine is added to dissolve, polyethylene glycol is added to dissolve;

[0023] (3) The solution obtained in step (2) was cooled to room temperature while stirring, and sodium carboxymethylcellulose was added and stirred for 30 minutes; carbonyl iron powder was ...

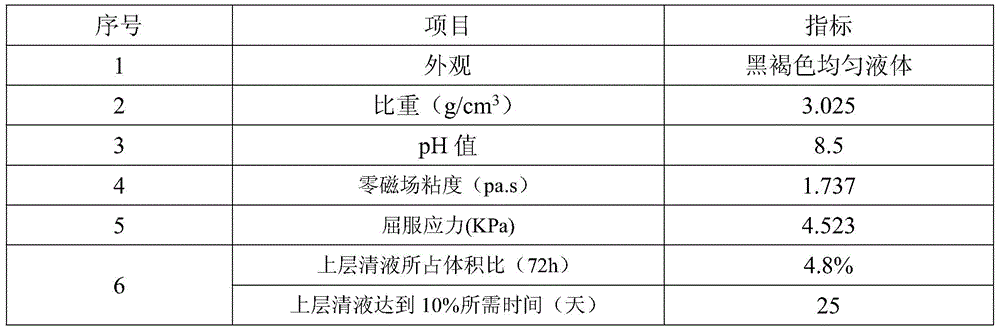

Embodiment 2

[0029] A method for preparing a special magnetorheological fluid for optical glass polishing, comprising the following steps:

[0030] (1) Take the following components by weight percentage: 50% of carbonyl iron powder, 10% of diamond particles with a particle diameter of 20 μm, 3% of sodium carboxymethyl cellulose, 1% of sodium carbonate, polyethylene glycol 6002%, Triethanolamine 1%, potassium tetraborate 0.5%, benzotriazole 1.5%, hexamethylenetetramine 0.4%, purified water 30.6%;

[0031] (2) At room temperature, add sodium carbonate to water and stir to dissolve; heat, at 60°C, add potassium tetraborate while stirring to dissolve, add benzotriazole to dissolve, add hexamethylenetetra Amine is dissolved, triethanolamine is added to dissolve, polyethylene glycol is added to dissolve;

[0032] (3) The solution obtained in step (2) was cooled to room temperature while stirring, and sodium carboxymethylcellulose was added and stirred for 20 minutes; carbonyl iron powder was ad...

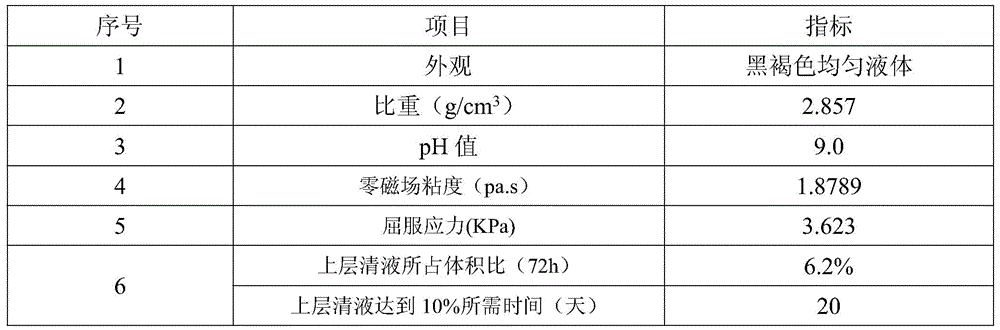

Embodiment 3

[0039] A method for preparing a special magnetorheological fluid for optical glass polishing, comprising the following steps:

[0040] (1) Take the following components by weight percentage: 30% of carbonyl iron powder, 5% of diamond particles with a particle diameter of 10 μm, 5% of sodium carboxymethyl cellulose, 1% of sodium carbonate, polyethylene glycol 6002%, Triethanolamine 0.5%, potassium tetraborate 1%, benzotriazole 2%, hexamethylenetetramine 1%, purified water 52.5%;

[0041] (2) At room temperature, add sodium carbonate to water and stir to dissolve; heat, at 50°C, add potassium tetraborate while stirring to dissolve, add benzotriazole to dissolve, add hexamethylenetetra Amine is dissolved, triethanolamine is added to dissolve, polyethylene glycol is added to dissolve;

[0042] (3) The solution obtained in step (2) was cooled to room temperature while stirring, and sodium carboxymethylcellulose was added and stirred for 30 minutes; carbonyl iron powder was added u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com